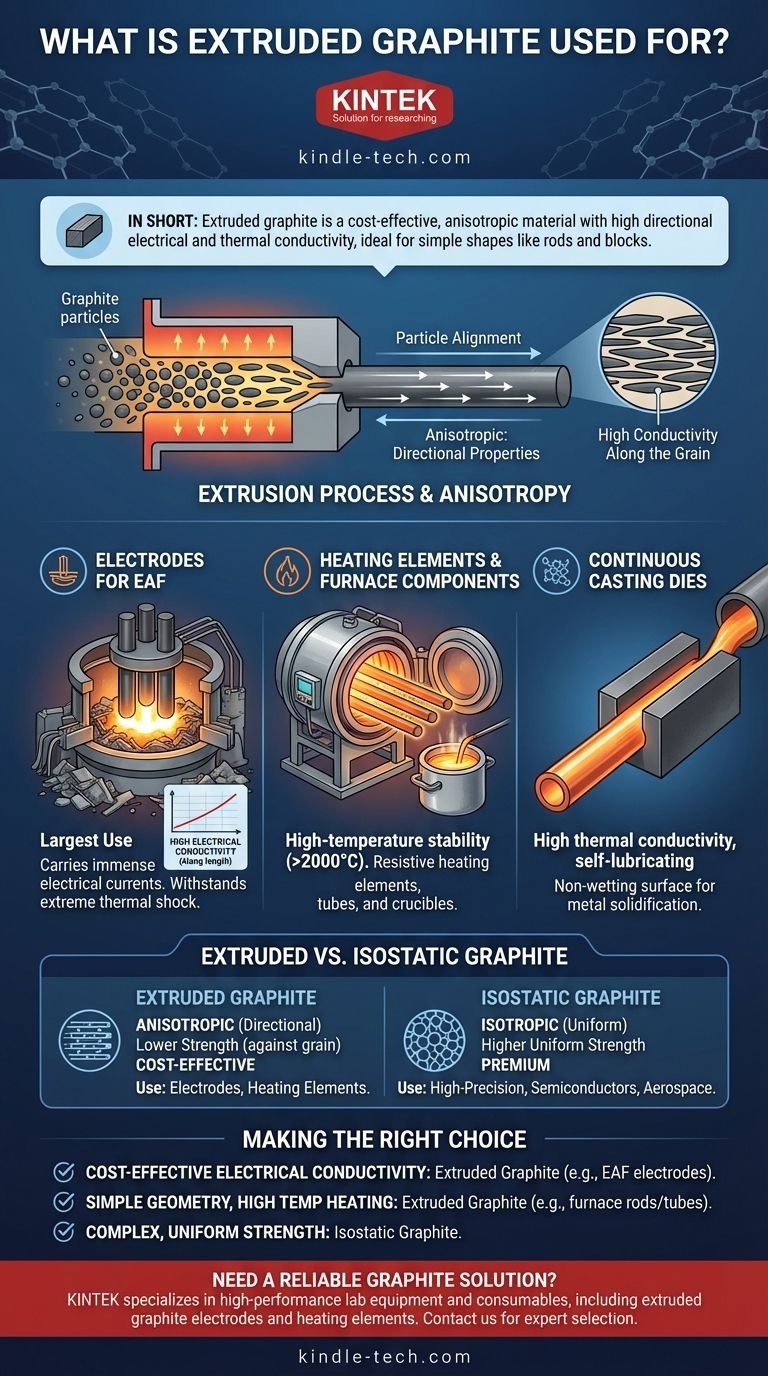

In short, extruded graphite is primarily used for applications where cost-effectiveness and high electrical or thermal conductivity in a specific direction are critical. Its most common uses are as electrodes in electric arc furnaces for steel recycling, heating elements in high-temperature industrial furnaces, and crucibles for melting metals.

The core principle to understand is that the extrusion process aligns the graphite particles, creating a material with excellent directional properties. This makes it the ideal, economical choice for simpler shapes like rods and blocks but less suitable for complex components requiring uniform strength in all directions.

The Defining Properties of Extruded Graphite

To understand its applications, we must first understand how extruded graphite is made and what characteristics result from that process. It is not an all-purpose material; it is a specialized tool for specific jobs.

The Extrusion Process and Anisotropy

Extruded graphite is produced by mixing petroleum coke and a binder, heating it, and forcing it through a die to form a shape, typically a rod or block.

This process forces the flat, plate-like graphite particles to align parallel to the direction of extrusion. This alignment creates a material that is anisotropic, meaning its properties are different when measured along the grain versus against the grain.

Directional Conductivity

The primary consequence of this anisotropy is excellent electrical and thermal conductivity along the length of the extruded shape (with the grain). The aligned particles create an efficient path for electricity and heat to travel.

Conductivity is significantly lower when measured across the grain, a crucial factor in engineering design.

Cost-Effectiveness

Compared to other methods of producing synthetic graphite, such as isostatic pressing, extrusion is a more economical, high-volume manufacturing process. This makes it the default choice for applications that consume large quantities of graphite.

Primary Applications in Detail

The unique combination of conductivity, high-temperature stability, and cost-effectiveness makes extruded graphite indispensable in several key industries.

Electrodes for Electric Arc Furnaces (EAF)

This is the largest single use for extruded graphite. Massive graphite electrodes, often over two feet in diameter, are used to carry immense electrical currents into electric arc furnaces.

The current melts scrap steel as part of the recycling process. Extruded graphite is the only material that can provide the required electrical conductivity and withstand the extreme thermal shock of this environment at an acceptable cost.

Heating Elements and Furnace Components

In vacuum or inert-atmosphere furnaces that operate at very high temperatures, extruded graphite rods and tubes are often used as resistive heating elements.

Their ability to maintain strength and conduct electricity at temperatures well over 2000°C is critical. They are also formed into crucibles for metallurgical processes involving the melting of non-ferrous metals.

Continuous Casting Dies

In the production of metals like copper and aluminum, molten metal is often pulled through a die to form rods, tubes, and other shapes.

Extruded graphite is an excellent material for these dies due to its high thermal conductivity (which helps solidify the metal), self-lubricating nature, and the fact that most molten metals will not wet its surface.

Understanding the Trade-offs: Extruded vs. Isostatic Graphite

Choosing the right type of graphite is critical. The most common alternative to extruded graphite is isostatic graphite, which serves a very different purpose.

Anisotropy vs. Isotropy

As we've covered, extruded graphite is anisotropic. Its strength and conductivity are directional.

Isostatic graphite is made by pressing graphite powder from all directions at once, resulting in a random particle orientation. This makes it isotropic, meaning its properties are uniform and consistent in all directions.

Strength and Grain Structure

Isostatic graphite has a much finer grain structure and higher mechanical strength. Its uniformity makes it ideal for machining intricate, high-precision components that cannot have weak points.

Extruded graphite has a larger grain structure and lower mechanical strength, particularly against the grain. It is not suitable for complex structural parts that experience multi-directional stress.

Cost and Performance

This is the essential trade-off. Extruded graphite is the cost-effective workhorse. Isostatic graphite is a premium, high-performance material used in demanding, advanced applications like semiconductor manufacturing, nuclear reactors, and aerospace components.

Making the Right Choice for Your Goal

Your application's specific requirements for performance, geometry, and cost will determine which material is appropriate.

- If your primary focus is cost-effective electrical conductivity for large-scale processes: Extruded graphite is the industry standard for applications like electric arc furnace electrodes.

- If your primary focus is high-temperature heating elements with simple geometries: Extruded graphite offers the best balance of performance and cost for furnace components like rods and tubes.

- If your primary focus is complex components requiring uniform strength and fine detail: You must specify a higher-grade isotropic material, such as isostatic graphite.

Ultimately, selecting the correct material begins with understanding that not all graphite is created equal.

Summary Table:

| Property | Extruded Graphite | Isostatic Graphite |

|---|---|---|

| Structure | Anisotropic (directional) | Isotropic (uniform) |

| Primary Use | Electrodes, heating elements, crucibles | High-precision components, semiconductors |

| Cost | Cost-effective | Premium |

| Strength | Directional, lower against the grain | High, uniform in all directions |

Need a reliable graphite solution for your industrial or lab application? KINTEK specializes in high-performance lab equipment and consumables, including extruded graphite components like electrodes and heating elements. Our experts can help you select the right material for cost-effective conductivity and high-temperature stability. Contact us today to discuss your specific needs and enhance your process efficiency with KINTEK's trusted solutions.

Visual Guide

Related Products

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- High Purity Pure Graphite Crucible for Evaporation

- 1200℃ Muffle Furnace Oven for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of electron beam hardening? Achieve Superior Precision and Speed

- What is the point of sintering? Create Strong, Complex Parts Without Melting

- What is the electric arc furnace? A Sustainable Solution for Modern Steel Recycling

- How does a laboratory electric drying oven contribute to the formation of the initial coating? Expert Insights

- What core process function does a Laboratory Oven perform during the coating modification of glass fiber membranes?

- What is the difference between batch furnace and continuous furnace? Choose the Right System for Your Production Volume

- How does a precision oven ensure epoxy and nanosheet coating quality? Achieve Perfect Cross-Linking and Bond Strength

- How does the sputtering process work? A Guide to Thin Film Deposition