In essence, plasma arc technology is a method of waste disposal that uses extremely high temperatures to break down waste into its fundamental chemical components. Instead of burning waste through combustion, it uses plasma—an electrically charged gas often called the fourth state of matter—to convert solid or liquid waste into a combustible gas and a non-hazardous, glass-like solid.

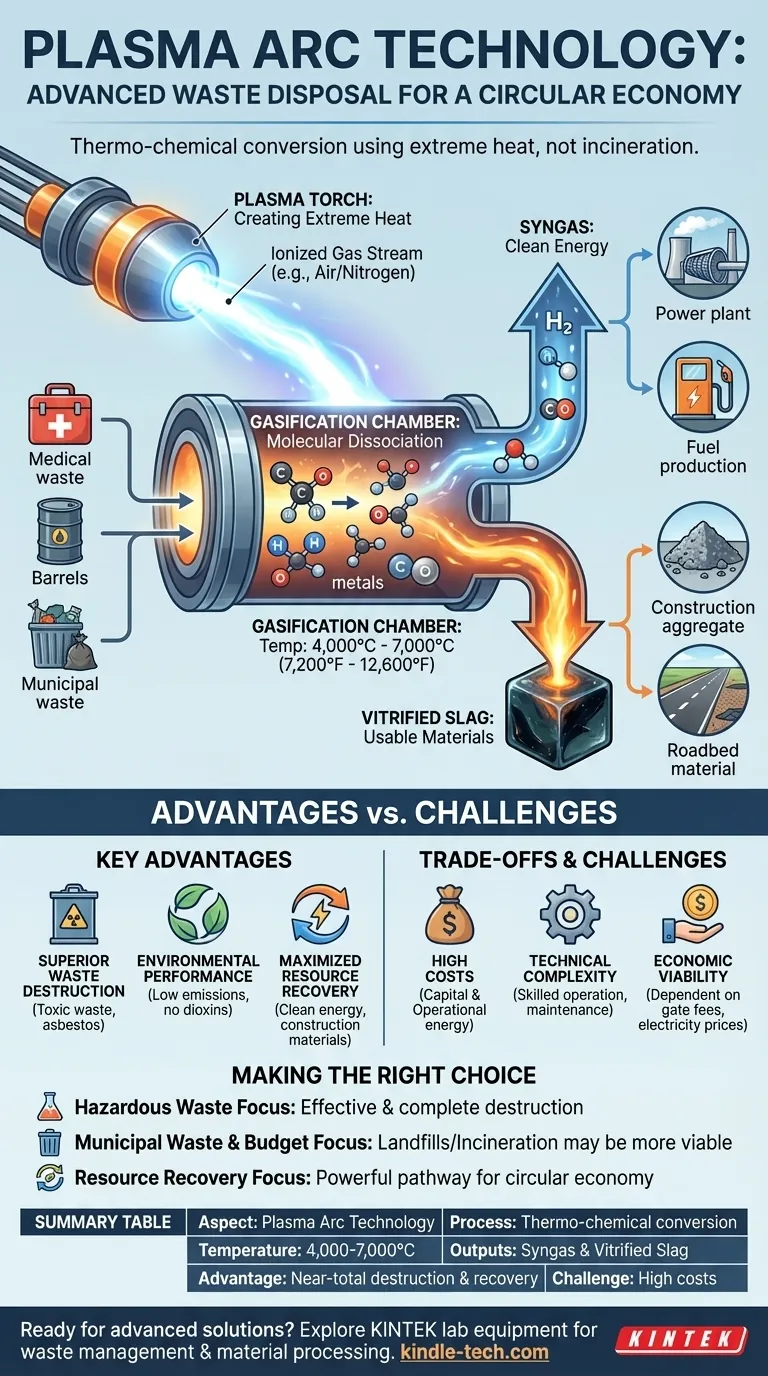

The core principle to understand is that plasma gasification is not incineration. It is a thermo-chemical conversion process that deconstructs waste at a molecular level, transforming a liability into valuable resources like clean energy and construction materials.

How Plasma Gasification Works

To understand the technology's potential, we must first look at the core mechanics of the process, which happens in a controlled, low-oxygen environment.

The Plasma Torch: Creating Extreme Heat

The heart of the system is the plasma torch, which uses a high-voltage electric current to ionize a gas (like air or nitrogen), creating a plasma stream.

This process generates immense heat, with temperatures inside the gasifier reaching between 4,000°C and 7,000°C (7,200°F to 12,600°F)—hotter than the surface of the sun.

The Gasification Chamber: Molecular Dissociation

Waste material is fed into a sealed chamber, known as a gasifier. The intense heat from the plasma torch doesn't burn the waste in the traditional sense because of the very low oxygen levels.

Instead, the energy is so powerful it causes molecular dissociation. Organic materials are broken down into their simplest constituent elements, primarily forming a synthetic gas.

The Primary Outputs: Syngas and Vitrified Slag

The process results in two main, highly stable, and useful byproducts.

- Syngas: A mixture of primarily hydrogen (H₂) and carbon monoxide (CO). This gas can be cleaned of impurities and then used as a fuel in gas turbines or engines to generate electricity, or as a chemical building block for producing fuels like ethanol.

- Vitrified Slag: The inorganic components of the waste (glass, metals, soil) melt and fuse together. Upon cooling, they form a hard, inert, glass-like material called slag. This material is non-leachable, meaning hazardous elements are permanently trapped within its structure, making it safe for use as construction aggregate or in roadbeds.

Key Advantages Over Traditional Methods

Plasma gasification is considered a next-generation technology because it addresses many of the shortcomings of landfilling and conventional incineration.

Superior Waste Destruction

The extreme temperatures ensure the complete destruction of a wide range of waste, including highly toxic materials like medical waste, chemical sludge, and asbestos, which are difficult or impossible to treat otherwise.

Environmental Performance

Because the process is not based on combustion, it largely avoids the formation of toxic byproducts like dioxins and furans, which are a major concern with traditional incinerators. The resulting syngas is cleaned before it is used, allowing for much tighter control over emissions.

Maximized Resource Recovery

This technology embodies the principles of a circular economy. It diverts nearly 100% of waste from landfills and converts it into two valuable commodities: clean energy (from syngas) and usable materials (from slag).

Understanding the Trade-offs and Challenges

Despite its significant advantages, plasma gasification is not a universal solution. It comes with its own set of practical and economic hurdles.

High Capital and Operational Costs

Plasma facilities are extremely expensive to build. Furthermore, the plasma torches consume a significant amount of electricity, making the operational energy cost one of the primary economic challenges.

Technical Complexity

Operating a plasma gasification plant requires highly skilled personnel. The technology is complex, and maintaining the systems, especially the high-temperature refractory linings and the plasma torches themselves, can be demanding.

Economic Viability

The business case for a plasma facility often depends on a combination of factors: high "gate fees" for accepting waste (especially hazardous waste), the local price of electricity, a stable market for the slag, and government subsidies for renewable energy. Without these, economic feasibility can be difficult to achieve.

Making the Right Choice for Your Goal

Deciding whether to implement plasma gasification requires a clear understanding of the specific waste problem you are trying to solve.

- If your primary focus is destroying hazardous or specialized waste: Plasma gasification is one of the most effective and environmentally sound technologies available for ensuring complete destruction and containment.

- If your primary focus is managing large volumes of municipal solid waste on a strict budget: The high capital and operational costs may make advanced landfills or modern waste-to-energy incinerators a more economically viable choice.

- If your primary focus is maximizing resource recovery and achieving circular economy goals: Plasma gasification offers a powerful pathway to convert diverse waste streams into high-value energy and materials with minimal environmental impact.

Ultimately, plasma arc technology is a specialized and powerful tool in the modern waste management hierarchy, offering near-total waste conversion at the cost of high technical and financial investment.

Summary Table:

| Aspect | Plasma Arc Technology |

|---|---|

| Process | Thermo-chemical conversion (not incineration) |

| Temperature | 4,000°C - 7,000°C (7,200°F - 12,600°F) |

| Primary Outputs | Syngas (for energy) & Vitrified Slag (for construction) |

| Key Advantage | Near-total waste destruction and resource recovery |

| Main Challenge | High capital and operational costs |

Ready to explore advanced solutions for your laboratory's waste management and material processing needs?

At KINTEK, we specialize in providing cutting-edge lab equipment and consumables. Whether you are researching waste conversion technologies, developing new materials, or need reliable equipment for high-temperature processes, our expertise can help you achieve your goals efficiently and safely.

Contact us today to discuss how KINTEK can support your laboratory's specific challenges and drive your innovation forward.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition