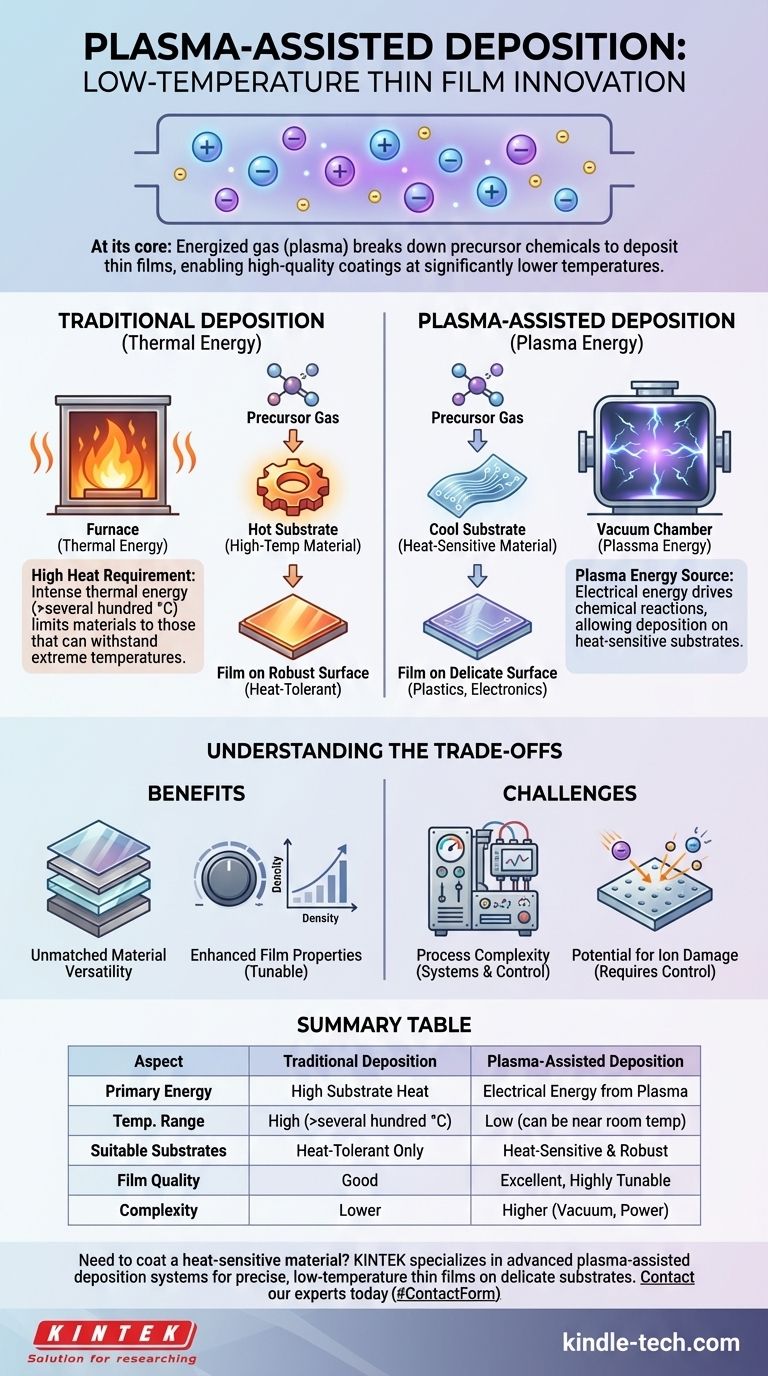

At its core, plasma-assisted deposition is a process that uses an energized gas, or plasma, to help deposit a thin film onto a material's surface. Unlike traditional methods that rely solely on high heat, this technique uses the energy within the plasma to break down precursor chemicals and form a coating. This allows for high-quality deposition at significantly lower temperatures.

The fundamental challenge with traditional deposition is the intense heat required, which limits the types of materials that can be coated. Plasma-assisted deposition solves this by using the electrical energy of a plasma to drive the necessary chemical reactions, opening the door to coating heat-sensitive substrates like plastics and complex electronics.

How Traditional Deposition Sets the Stage

The High-Heat Requirement

In a conventional process like Chemical Vapor Deposition (CVD), a precursor gas is introduced into a chamber containing the object to be coated (the substrate).

The substrate is heated to very high temperatures, often several hundred or even over a thousand degrees Celsius. This intense thermal energy breaks the chemical bonds in the gas, causing the material to deposit as a solid thin film on the hot surface.

The Limitations of Heat

The reliance on high heat creates a major constraint: it can only be used on substrates that can withstand it.

Materials like plastics, polymers, or delicate electronic components would be damaged, melted, or destroyed by the temperatures required for traditional CVD. This severely limits the range of potential applications.

The Role of Plasma: A New Energy Source

Creating the Plasma

Plasma is often called the fourth state of matter. In this process, a gas (like argon or nitrogen) is introduced into a vacuum chamber and energized, typically by applying a strong electric field.

This energy strips electrons from the gas atoms, creating a highly reactive mixture of ions, electrons, and neutral radical species. This energized gas is the plasma.

Activating the Precursor Gas

The true innovation happens when the precursor gas (the source of the coating material) is introduced into this plasma.

The high-energy electrons and radicals in the plasma collide with the precursor gas molecules. These collisions transfer enough energy to break the chemical bonds—a task previously accomplished only by extreme heat.

Enabling Low-Temperature Deposition

Because the plasma provides the energy needed for the chemical reaction, the substrate itself no longer needs to be the primary heat source.

The substrate can remain at a much lower temperature while the activated chemical species condense and form a high-quality, dense film on its surface.

Understanding the Trade-offs

Benefit: Unmatched Material Versatility

The most significant advantage is the ability to coat materials that are sensitive to heat. This makes it possible to apply hard, protective, or functional coatings to plastics, flexible electronics, and other temperature-limited substrates.

Benefit: Enhanced Film Properties

The energy supplied by the plasma can be precisely controlled. This allows for fine-tuning the properties of the resulting film, such as its density, adhesion, and internal stress, often achieving results not possible with purely thermal methods.

Challenge: Process Complexity

Introducing a plasma source adds layers of complexity. The process requires sophisticated vacuum systems, radio-frequency (RF) or direct-current (DC) power supplies, and meticulous control over gas pressure, flow rates, and power levels.

Challenge: Potential for Ion Damage

While the plasma's energy is useful, the high-energy ions can also bombard the surface of the growing film. If not properly controlled, this bombardment can introduce defects or stress, potentially compromising the film's quality.

Making the Right Choice for Your Goal

Selecting the right deposition method requires a clear understanding of your material constraints and desired outcome.

- If your primary focus is coating heat-sensitive materials: Plasma-assisted deposition is often the superior, and sometimes only, viable method for creating a durable thin film.

- If your primary focus is high-volume coating of robust, heat-tolerant materials: Traditional thermal CVD might be a simpler and more cost-effective solution if its high-temperature nature is not a limitation.

- If your primary focus is achieving highly specific film characteristics: The precise control over energy and ion bombardment in a plasma process can provide unique capabilities for engineering material properties.

By viewing plasma as a tunable energy source rather than just a process, you can select the precise method your application truly requires.

Summary Table:

| Aspect | Traditional Deposition | Plasma-Assisted Deposition |

|---|---|---|

| Primary Energy Source | High substrate heat | Electrical energy from plasma |

| Typical Substrate Temperature | High (hundreds to >1000°C) | Low (can be near room temperature) |

| Suitable Substrates | Heat-tolerant materials only | Heat-sensitive materials (plastics, electronics) |

| Film Quality & Control | Good | Excellent, highly tunable |

| Process Complexity | Lower | Higher (requires vacuum, RF/DC power) |

Need to coat a heat-sensitive material?

KINTEK specializes in advanced lab equipment, including plasma-assisted deposition systems, to help you achieve precise, low-temperature thin films on even the most delicate substrates like plastics and complex electronics. Our expertise ensures you get the right solution for your specific material challenges.

Contact our experts today to discuss how we can enhance your coating process!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the advantages of plasma enhanced chemical vapor deposition? Enable Low-Temperature, High-Quality Film Deposition

- What are the advantages of plasma CVD? Achieve Superior Low-Temperature Thin Film Deposition

- How does PECVD equipment facilitate SiC deposition on sensitive substrates? Unlock Low-Temp Thin Film Solutions

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the primary purposes of utilizing alumina or quartz dielectric layers in DBD reactors? Ensure Plasma Stability

- How does a rotating sample stage improve PECVD coatings? Achieve Uniformity for Porous Membranes

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is Plasma Enhanced Chemical Vapor Deposition (PECVD)? High-Quality Film Deposition at Low Temperatures