At its core, plasma discharge sintering is a high-speed consolidation technique for powdered materials. Also known as Spark Plasma Sintering (SPS) or Field-Assisted Sintering Technique (FAST), it uses pulsed direct electrical current and uniaxial pressure to fuse particles together. The process generates a discharge plasma between the powder particles, creating rapid, localized heating that achieves full material density in minutes at significantly lower temperatures than conventional methods.

While traditional sintering relies on slow, external furnace heating, plasma discharge sintering uses a direct electrical current to heat the material internally and externally, achieving superior densification with unprecedented speed and efficiency.

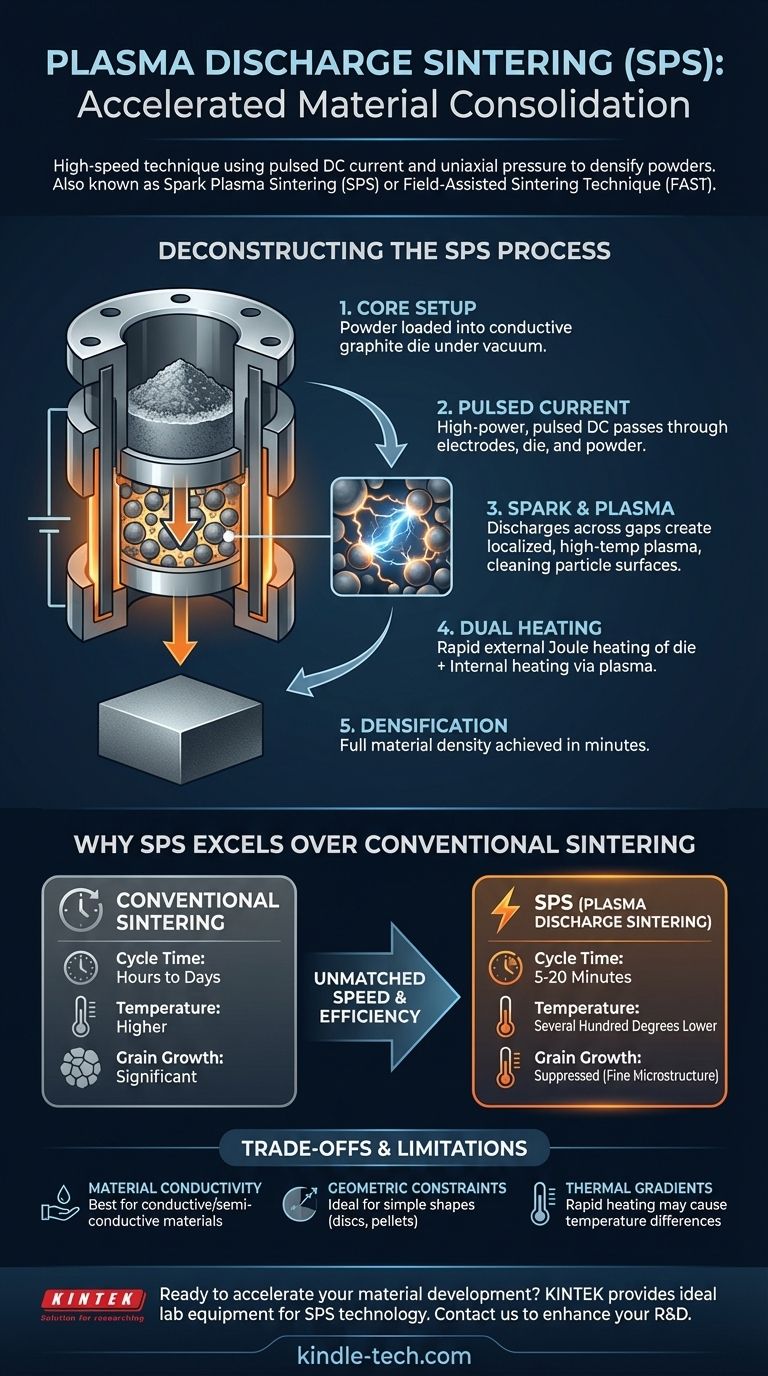

Deconstructing the SPS Process

To understand plasma discharge sintering, it's best to break down its unique mechanism. The combination of electrical current and pressure creates an environment unlike any other sintering method.

The Core Setup

The process begins by loading a loose powder into a conductive die, which is typically made of graphite. This die assembly is then placed between two electrodes within a vacuum chamber and subjected to mechanical pressure.

The Role of Pulsed Current

Once under pressure, a high-power, pulsed direct current (DC) is passed directly through the electrodes, the conductive die, and the powder itself. This direct application of energy is the defining feature of the technique.

The Spark and Plasma Generation

The "spark" or "plasma" is the key to the process's efficiency. At the microscopic level, the electrical current creates discharges or sparks across the tiny gaps between individual powder particles. These discharges generate localized, high-temperature plasma—an ionized gas—that strips away contaminants and activates the particle surfaces, preparing them for bonding.

A Dual Heating Mechanism

Heating is extraordinarily fast because it happens in two ways simultaneously. The entire graphite die heats up due to electrical resistance (Joule heating), heating the powder externally. At the same time, the current passing through the powder and the plasma discharges between particles provide direct internal heating.

Why SPS Excels Over Conventional Sintering

The unique heating mechanism gives SPS significant advantages over traditional furnace-based sintering, which has been the standard for decades in ceramics and powder metallurgy.

Unmatched Speed

An SPS cycle is typically completed in 5 to 20 minutes. In contrast, a conventional sintering process can take many hours or even days. This is due to the extremely rapid heating and cooling rates (up to 1000°C/minute) that direct electrical heating allows.

Lower Sintering Temperatures

SPS consistently achieves full densification at temperatures several hundred degrees lower than conventional methods. The plasma activation of particle surfaces enhances the diffusion and bonding processes, so less thermal energy is required to fuse the material.

Preserving Material Microstructure

The combination of lower temperatures and extremely short processing times is critical for materials science. It suppresses grain growth, allowing for the creation of materials with very fine, and often superior, mechanical properties like strength and hardness.

Understanding the Trade-offs and Limitations

Despite its power, plasma discharge sintering is not a universal solution. Its specific mechanism brings about a unique set of constraints that must be considered.

Material and Die Conductivity

The process relies on current flowing through the die and, ideally, the sample. This makes it exceptionally well-suited for conductive and semi-conductive materials. While insulating ceramics can be sintered, it requires careful die design and process control as heating is less direct.

Geometric Constraints

The need for a rigid, uniaxial die limits the complexity of the parts that can be produced. The technique is ideal for simple geometries like discs, pellets, and rectangular blocks but is not suitable for intricate, three-dimensional shapes.

Potential for Thermal Gradients

The extremely rapid heating can sometimes create temperature differences between the core and the surface of a large sample. Managing these thermal gradients is a key parameter for ensuring the final part is uniform and free of stress.

Making the Right Choice for Your Goal

Selecting the appropriate sintering technique depends entirely on your material, desired geometry, and final performance requirements.

- If your primary focus is rapid material discovery or processing advanced composites: SPS is the ideal choice due to its speed, low-temperature processing, and ability to preserve novel microstructures.

- If your primary focus is mass-producing complex metal or ceramic shapes: A traditional press-and-sinter process or metal injection molding (MIM) is often more cost-effective and geometrically flexible.

- If your primary focus is densifying materials with extremely high melting points: SPS offers significant energy and time savings over conventional high-temperature furnaces, resulting in superior final properties.

Ultimately, plasma discharge sintering empowers engineers and scientists to create dense, high-performance materials that were previously difficult or impossible to fabricate efficiently.

Summary Table:

| Feature | Plasma Discharge Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Cycle Time | 5 - 20 minutes | Hours to Days |

| Typical Temperature | Several hundred degrees lower | Higher |

| Grain Growth | Suppressed (fine microstructure) | More significant |

| Ideal For | Rapid R&D, advanced composites, high-melting-point materials | Mass production of complex shapes |

Ready to accelerate your material development with superior sintering?

Plasma discharge sintering is a powerful tool for creating dense, high-performance materials with fine microstructures. If you are researching advanced composites, ceramics, or other specialized materials, KINTEK can provide the ideal lab equipment to harness the speed and efficiency of SPS technology.

Contact KINTEK today to discuss how our sintering solutions can enhance your R&D and help you achieve groundbreaking results faster.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the process advantages of using a vacuum hot press vs. HIP? Simplify your steel preparation workflow.

- What is the primary function of a hot pressing furnace? Achieve High-Density LLZO/LLTO Electrolytes

- What is the primary role of the Vacuum Hot Pressing Sintering Furnace? Prepare High-Purity W-Si Alloy Targets

- What conditions does a vacuum hot press provide for Al2O3/ZrO2 sintering? Achieve 1550°C and 30 MPa Densification

- What is the function of a hot press in UHTCMC densification? Master High-Strength Ceramic Consolidation

- What are the advantages of spark plasma sintering? Achieve Faster, Superior Material Densification

- What is the primary function of a Vacuum Hot Pressing Furnace in Ti/Al composites? Optimize Bond Quality & Purity

- How is hot isostatic pressing done? A Complete Guide to the HIP Process