Plasma melting is a high-purity metallurgical process that uses a jet of high-temperature ionized gas (plasma) to melt metals and other materials. Unlike conventional methods that heat the material indirectly, a plasma arc transfers intense, concentrated energy directly to the target, enabling extremely high temperatures and precise control.

The central advantage of plasma melting is not just its heat, but its precision and purity. It creates an ultra-clean melting environment, making it the superior choice for producing high-performance alloys and processing reactive metals that would be contaminated by other methods.

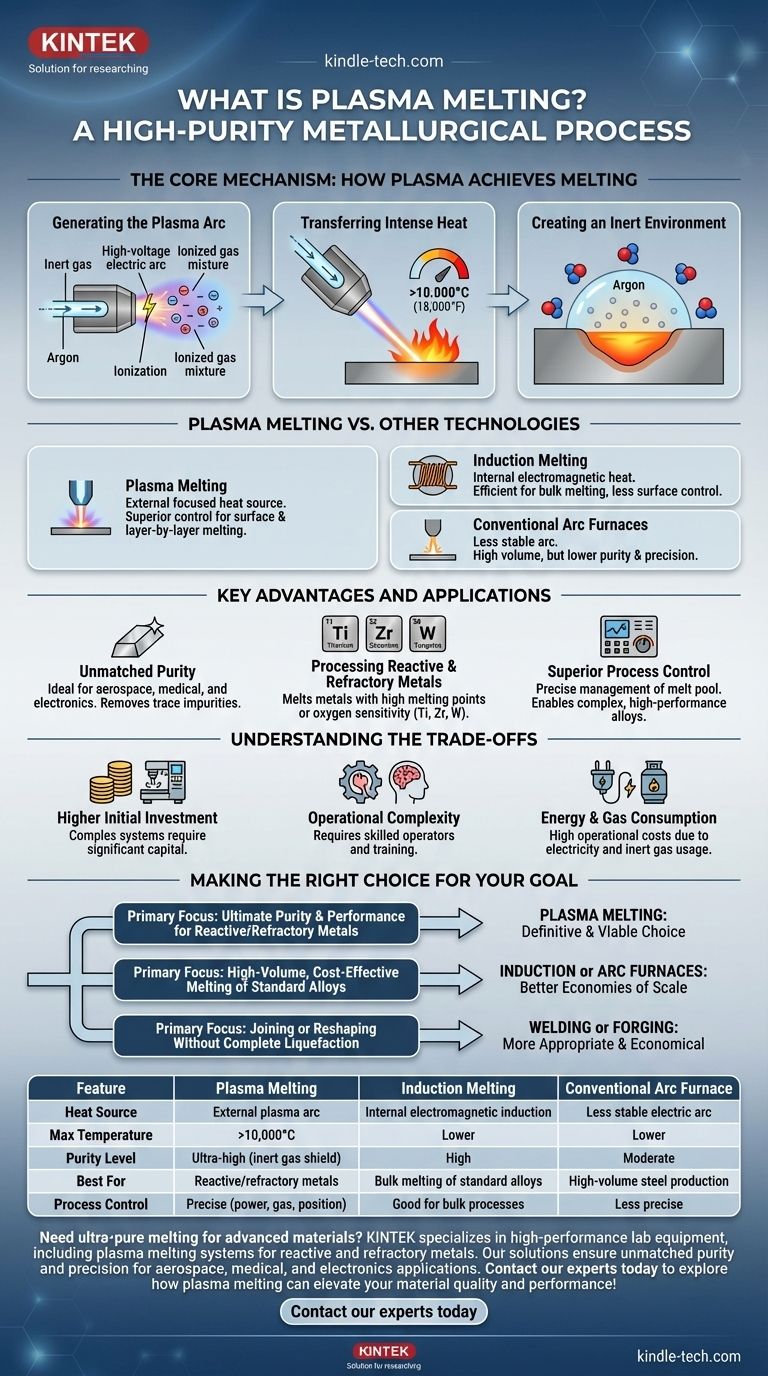

The Core Mechanism: How Plasma Achieves Melting

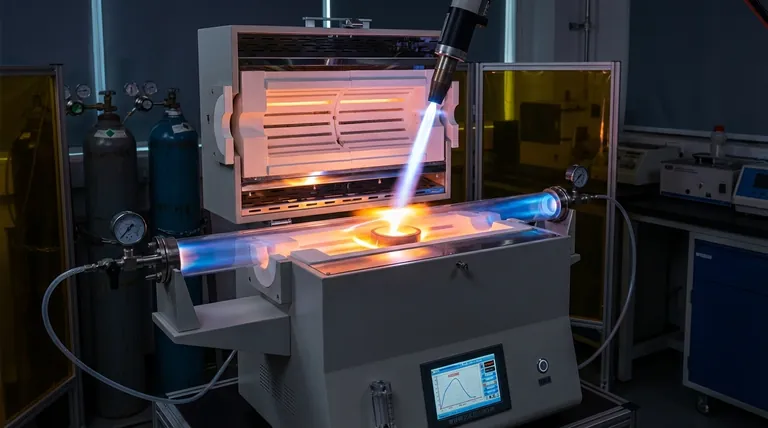

Plasma melting technology is centered around the plasma torch, which functions as a highly controlled heat source. The process is both elegant and powerful, relying on fundamental principles of physics to achieve its results.

Generating the Plasma Arc

A plasma torch works by passing an inert gas, such as argon, through a high-voltage electric arc. This intense energy strips electrons from the gas atoms, a process called ionization. The resulting mixture of ions and electrons is plasma—an electrically conductive state of matter.

Transferring Intense Heat

This plasma is forced through a nozzle at high velocity, creating a focused jet that can reach temperatures exceeding 10,000°C (18,000°F). When this jet strikes the target metal, it transfers its thermal energy with incredible efficiency, causing rapid and localized melting.

Creating an Inert Environment

Because the process uses an inert gas like argon, the molten metal is shielded from oxygen and nitrogen in the atmosphere. This prevents the formation of oxides and nitrides, which are impurities that can degrade the quality and performance of the final material.

Plasma Melting vs. Other Technologies

To understand the value of plasma melting, it's essential to compare it to more common industrial processes. Its unique characteristics make it suitable for applications where other methods fall short.

Comparison with Induction Melting

Induction melting, as described in the references, uses an electromagnetic field to generate heat within the metal itself. This is highly efficient for bulk melting but offers less control over the surface and can be less effective for materials with poor electrical conductivity.

Plasma melting, in contrast, applies heat externally with a focused arc. This provides superior control for surface treatments and for melting materials in a more controlled, layer-by-layer fashion if needed.

Comparison with Conventional Arc Furnaces

Traditional electric arc furnaces also use an electric arc, but it is much less stable and focused than a plasma jet. They are the workhorses of steel recycling and production but do not offer the same level of purity or temperature control as a plasma system.

Key Advantages and Applications

The unique properties of plasma melting give it distinct advantages in specialized, high-value manufacturing and materials science.

Unmatched Purity

The inert gas environment and the clean nature of the heat source result in an exceptionally pure final product. This is critical for applications in the aerospace, medical, and electronics industries, where even trace impurities can lead to material failure.

Processing Reactive and Refractory Metals

Plasma is the ideal technology for melting metals like titanium, zirconium, and tungsten. These metals have very high melting points (refractory) or react aggressively with oxygen at high temperatures (reactive). Plasma melting solves both challenges simultaneously.

Superior Process Control

The operator has precise control over the power, gas flow, and position of the plasma arc. This allows for meticulous management of the melt pool, ensuring consistent quality and enabling the creation of complex, high-performance alloys.

Understanding the Trade-offs

No technology is without its limitations. Objectivity requires acknowledging where plasma melting may not be the best fit.

Higher Initial Investment

Plasma melting systems are complex and require a significant capital investment compared to traditional furnaces. The torches, power supplies, and gas management systems are sophisticated pieces of equipment.

Operational Complexity

Operating a plasma furnace requires a higher level of skill and training. Managing the process parameters to ensure optimal results is more demanding than operating simpler melting systems.

Energy and Gas Consumption

While efficient at transferring heat, plasma systems consume a substantial amount of electricity and inert gas. This makes the operational costs higher, particularly for large-scale production where economy of scale is a primary driver.

Making the Right Choice for Your Goal

Selecting the correct melting technology depends entirely on your material, your desired outcome, and your budget.

- If your primary focus is ultimate purity and performance for reactive or refractory metals: Plasma melting is the definitive and often the only viable choice.

- If your primary focus is high-volume, cost-effective melting of standard alloys like steel or aluminum: Induction or conventional electric arc furnaces offer better economies of scale.

- If your primary focus is joining or reshaping existing components without complete liquefaction: Other methods like welding or forging are more appropriate and economical.

Ultimately, adopting plasma melting is a strategic decision to prioritize material quality and performance above all else.

Summary Table:

| Feature | Plasma Melting | Induction Melting | Conventional Arc Furnace |

|---|---|---|---|

| Heat Source | External plasma arc | Internal electromagnetic induction | Less stable electric arc |

| Max Temperature | >10,000°C (18,000°F) | Lower than plasma | Lower than plasma |

| Purity Level | Ultra-high (inert gas shield) | High | Moderate |

| Best For | Reactive/refractory metals (Titanium, Tungsten) | Bulk melting of standard alloys | High-volume steel production |

| Process Control | Precise (power, gas flow, position) | Good for bulk processes | Less precise |

Need ultra-pure melting for advanced materials? KINTEK specializes in high-performance lab equipment, including plasma melting systems for reactive and refractory metals. Our solutions ensure unmatched purity and precision for aerospace, medical, and electronics applications. Contact our experts today to explore how plasma melting can elevate your material quality and performance!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Vacuum Arc Induction Melting Furnace

People Also Ask

- What is a temperature control system for digital applications? The Key to Reliable Electronics Performance

- What are the changes in quartz during heating and the possible effects on Si production? | Managing Quartz Transformation

- What are the products of sintering? Achieve Durable, Complex Parts from Powder

- What are the key features of slow pyrolysis and fast pyrolysis? Choose the Right Process for Bio-Oil or Biochar

- Why pyrolysis is better than incineration? Transforming Waste into Valuable Resources

- What is sputtering of nano materials? The Ultimate Guide to Thin Film Deposition

- What role does loading equipment play in strain field monitoring verification? Precision Control for Sensor Validation

- What is the function of KBr? A Key Tool for High-Quality FTIR Analysis of Solids