In materials science and manufacturing, a pressing die is a high-precision tool used to confine and compress loose powder into a solid, defined shape under immense force. These specialized molds are essential for creating dense, uniform pellets or components from a wide range of materials, primarily for analytical testing or industrial production.

A pressing die is more than a simple mold; it is a critical instrument designed to translate the force from a hydraulic press into a uniform, consolidated solid. The quality of the die directly determines the quality, density, and consistency of the final pressed part.

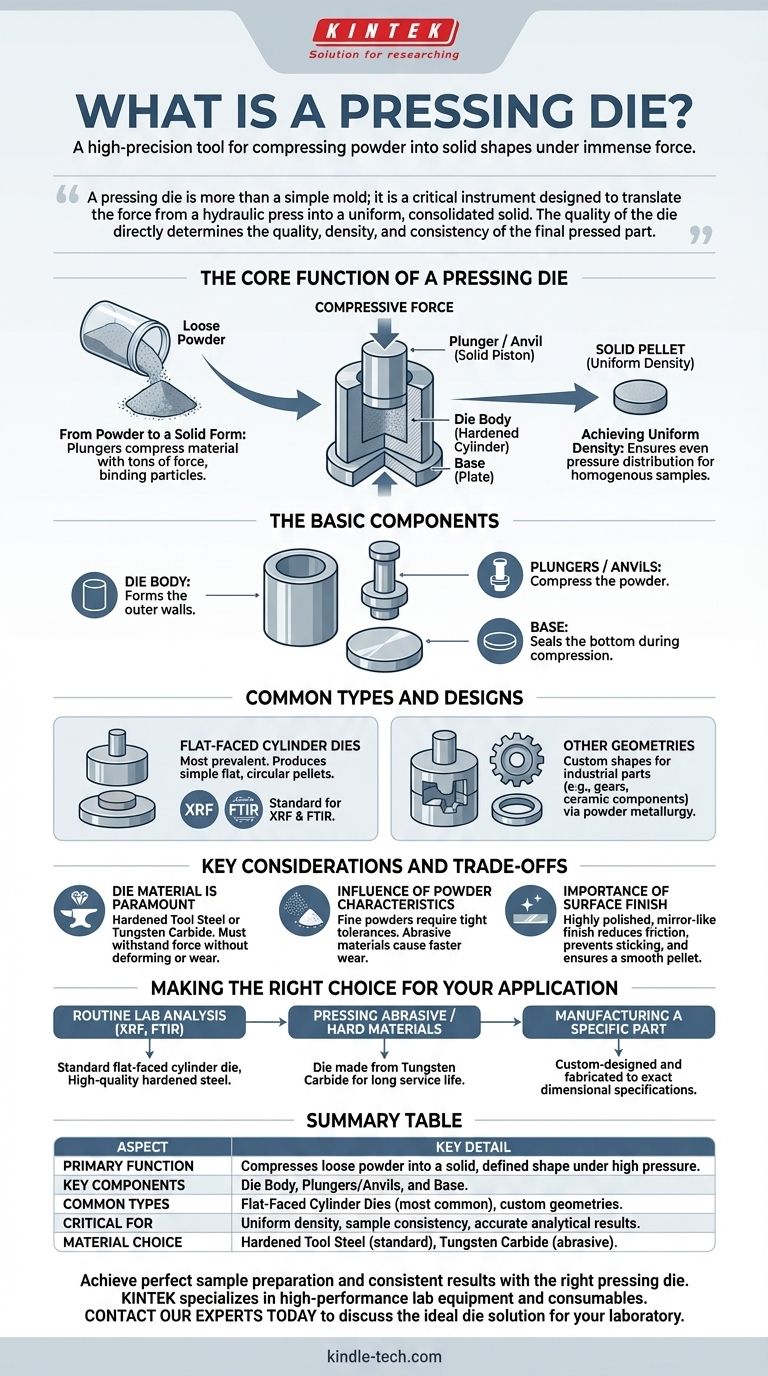

The Core Function of a Pressing Die

A die's primary role is to act as the forming chamber in a pressing operation. It must contain the powder, guide the compressive force, and allow for the ejection of the final solid pellet or component.

From Powder to a Solid Form

The die set consists of a hollow body (the mold cavity) and one or more plungers or anvils. Powder is loaded into the cavity, and the plungers compress the material with tons of force, forcing the individual particles to bind together.

Achieving Uniform Density

A well-designed die ensures that pressure is distributed as evenly as possible throughout the powder. This is critical for creating a homogenous sample without internal voids or weak points, which is especially important for analytical techniques that rely on sample consistency.

The Basic Components

Most pressing die sets include three main parts:

- The Die Body: A hardened cylinder that forms the outer walls of the sample.

- The Plungers (or Anvils): Solid pistons that fit perfectly inside the body to compress the powder.

- The Base: A plate that seals the bottom of the die body during compression.

Common Types and Designs

While many custom shapes exist, the most common designs are based on simple geometries suited for routine laboratory and industrial tasks. The choice depends entirely on the desired output and the nature of the material being pressed.

Flat-Faced Cylinder Dies

This is the most prevalent type, designed to produce simple flat, circular pellets or discs. Its simplicity and reliability make it the standard for preparing samples for analytical methods like X-Ray Fluorescence (XRF) and Fourier-Transform Infrared Spectroscopy (FTIR).

Other Geometries

Dies can be machined into virtually any shape, including squares, rings, and complex custom forms for producing industrial parts like gears, bushings, or ceramic components through a process known as powder metallurgy.

Key Considerations and Trade-offs

The performance and longevity of a pressing die depend on its material, the characteristics of the powder being used, and proper handling.

Die Material is Paramount

Pressing dies must be made from extremely hard, wear-resistant materials like hardened tool steel or tungsten carbide. They have to withstand immense compressive forces without deforming, cracking, or wearing down quickly, especially when working with abrasive powders.

The Influence of Powder Characteristics

The properties of your sample powder directly impact the pressing process. Fine powders may require tighter tolerances to prevent leakage, while abrasive materials will cause faster wear on the die surfaces.

The Importance of Surface Finish

The internal surface finish of the die is critical. A highly polished, mirror-like finish reduces friction, prevents the sample from sticking, and imparts a smooth surface on the final pellet, which is often necessary for accurate analysis.

Making the Right Choice for Your Application

Selecting the appropriate die is a critical step in ensuring repeatable and high-quality results. Your decision should be guided by your specific goal.

- If your primary focus is routine lab analysis (XRF, FTIR): A standard flat-faced cylinder die made from high-quality hardened steel is the most effective and economical choice.

- If your primary focus is pressing highly abrasive or hard materials: Investing in a die made from tungsten carbide is essential to ensure a long service life and consistent performance.

- If your primary focus is manufacturing a specific part: The die must be custom-designed and fabricated to the exact dimensional and geometric specifications of your final product.

Ultimately, understanding that the pressing die is a precision instrument is the key to achieving reliable and reproducible results in your work.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Compresses loose powder into a solid, defined shape under high pressure. |

| Key Components | Die Body, Plungers/Anvils, and Base. |

| Common Types | Flat-Faced Cylinder Dies (most common), and custom geometries. |

| Critical for | Uniform density, sample consistency, and accurate analytical results. |

| Material Choice | Hardened Tool Steel (standard) or Tungsten Carbide (abrasive materials). |

Achieve perfect sample preparation and consistent results with the right pressing die. The quality of your die directly impacts the density and integrity of your pellets for XRF, FTIR, and other analytical methods. KINTEK specializes in high-performance lab equipment and consumables, offering a range of durable pressing dies tailored to your specific material and application needs. Contact our experts today to discuss the ideal die solution for your laboratory.

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Polygon Press Mold for Lab

- Round Bidirectional Press Mold for Lab

- Special Shape Press Mold for Lab

People Also Ask

- What is mold in metal casting? The Essential Tool for Shaping Molten Metal

- What technical requirements must specialized pressure-bearing molds meet? Optimize Sulfide Electrolyte Densification

- How to keep ceramic clay from sticking to mold? Master Moisture Control for a Perfect Release

- What role does a graphite mold play during the SPS of LLZTO electrolytes? Optimize Your Solid-State Battery Research

- What measurement methods are commonly used for powder samples in infrared spectroscopy? Optimize Your FTIR Analysis

- What is positive compression molding? Achieve High-Precision, Zero-Waste Manufacturing

- What are the parts of a mold assembly? A Guide to Injection Mold Components

- What are the specific functions of graphite molds in the vacuum hot-press sintering process? Expert Insights for Ceramics