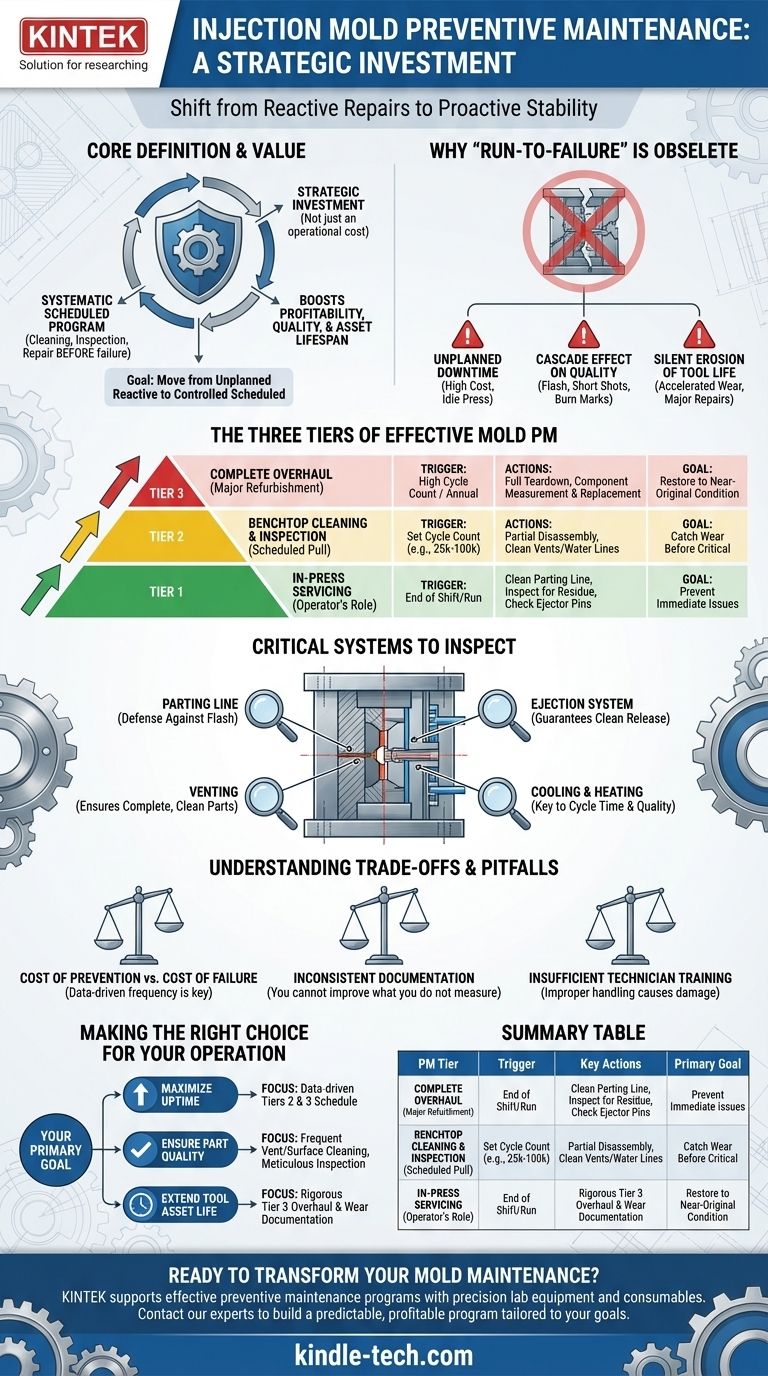

At its core, preventive maintenance (PM) for an injection mold is a systematic, scheduled program of cleaning, inspection, and repair performed before a failure occurs. It is the disciplined practice of servicing a tool based on a predetermined schedule—driven by cycle count or run time—rather than waiting for it to break down.

Mold PM is not an operational cost; it is a strategic investment in manufacturing stability. The goal is to shift your organization from expensive, unplanned reactive repairs to controlled, scheduled maintenance, directly boosting profitability, part quality, and asset lifespan.

Why "Run-to-Failure" Is No Longer Viable

Relying on reactive maintenance—fixing a mold only after it breaks—is a common but costly mistake. This approach introduces massive instability and hidden expenses into your operation.

The High Cost of Unplanned Downtime

When a mold fails unexpectedly during production, the press goes down. This stoppage incurs costs for the idle machine, the operator's time, and the missed production targets, often amounting to thousands of dollars per hour.

The Cascade Effect on Part Quality

Long before a catastrophic failure, a deteriorating mold produces inconsistent parts. Issues like flash (plastic seeping out of the parting line), short shots (incomplete parts), and burn marks from clogged vents lead to higher scrap rates and threaten customer relationships.

The Silent Erosion of Tool Life

Molds are significant capital assets. Running a tool until it fails often causes collateral damage, turning a simple component replacement into a major, expensive repair. A lack of PM accelerates wear and drastically shortens the tool's valuable service life.

The Three Tiers of Effective Mold PM

A robust PM program is not a single event but a tiered system. Each level has a specific trigger, scope, and purpose.

Tier 1: In-Press Servicing (The Operator's Role)

This is the most frequent and basic level of care, often performed by the machine operator at the end of a shift or production run. It involves cleaning the parting line surfaces, inspecting for residue, and ensuring ejector pins move freely. It is a quick check to prevent immediate issues.

Tier 2: Benchtop Cleaning & Inspection (The Scheduled Pull)

After a set number of cycles (e.g., 25,000 to 100,000), the mold is removed from the press and taken to the toolroom. Here, a technician performs a partial disassembly to clean all vents, water lines, and moving components. This is the core of most PM programs, catching wear before it becomes critical.

Tier 3: Complete Overhaul (Major Refurbishment)

This is a full teardown of the entire mold, scheduled after a very high cycle count or a set period (e.g., annually). Every single component—pins, bushings, plates, seals—is removed, measured against its original specifications, and replaced if worn. This restores the mold to near-original condition.

Critical Systems to Inspect

While every mold is unique, a successful PM program focuses on several universal, high-impact systems.

The Parting Line: Your First Defense Against Flash

The surfaces where the two halves of the mold meet are called the parting line. Even minor dings, wear, or contamination here will allow plastic to escape, creating flash on the part. Meticulous cleaning and protection of this surface are non-negotiable.

Venting: Ensuring a Complete and Clean Part

As plastic fills the mold cavity, the air inside must escape through tiny channels called vents. If these vents become clogged with residue, the trapped air can cause burn marks, incomplete parts, and dimensional instability.

The Ejection System: Guaranteeing a Clean Release

The system of ejector pins and plates is responsible for pushing the finished part out of the mold. Worn, bent, or poorly lubricated pins can damage the part, get stuck, or even break, causing significant downtime.

Cooling and Heating Systems: The Key to Cycle Time

The network of channels for water, oil, or heaters controls the mold's temperature. Scale buildup in cooling lines or failing thermocouples in a hot runner can lead to inconsistent part quality, warpage, and longer, less efficient cycle times.

Understanding the Trade-offs and Pitfalls

Implementing a PM program requires acknowledging its realities. Being aware of potential pitfalls is key to its success.

The Cost of Prevention vs. The Cost of Failure

PM requires scheduled downtime, labor, and a stock of spare parts. Management may see this as a cost, but it is minuscule compared to the cost of an emergency breakdown. The key is using data to find the optimal PM frequency—not too much, not too little.

The Pitfall of Inconsistent Documentation

A PM program without meticulous records is merely guesswork. You cannot improve what you do not measure. Every cleaning, inspection, and part replacement must be logged. This data reveals wear trends and allows you to predict future needs accurately.

The Danger of Insufficient Technician Training

A complex mold is a precision instrument. An improperly trained technician can cause more damage during disassembly and reassembly than the production run itself. Investing in proper training is essential for any PM program to be effective.

Making the Right Choice for Your Operation

A well-designed PM program directly supports your highest operational priorities. Use your primary goal to guide your focus.

- If your primary focus is maximizing uptime: Prioritize a data-driven schedule for Tier 2 and Tier 3 maintenance based on cycle counts to preemptively address wear before it can cause a line stoppage.

- If your primary focus is ensuring part quality: Concentrate on the frequent cleaning of vents, polishing cavity surfaces, and meticulous inspection of parting lines and gate areas during every PM event.

- If your primary focus is extending tool asset life: Implement a rigorous Tier 3 overhaul schedule and maintain meticulous documentation of component wear to justify and plan for major refurbishments.

Ultimately, preventive maintenance empowers you to take control of your manufacturing process, transforming uncertainty into predictable, profitable performance.

Summary Table:

| PM Tier | Trigger | Key Actions | Primary Goal |

|---|---|---|---|

| Tier 1: In-Press Servicing | End of shift/run | Clean parting line, inspect for residue | Prevent immediate issues |

| Tier 2: Benchtop Inspection | Set cycle count (25k-100k) | Clean vents/water lines, partial disassembly | Catch wear before critical |

| Tier 3: Complete Overhaul | High cycle count/annual | Full teardown, component measurement/replacement | Restore to near-original condition |

Ready to transform your mold maintenance from reactive to proactive? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision tools that support effective preventive maintenance programs. Our expertise helps you implement the right PM strategy to maximize uptime, ensure consistent part quality, and protect your valuable mold assets. Contact our experts today to discuss how we can help you build a predictable, profitable maintenance program tailored to your specific operational goals.

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- Ring Press Mold for Lab Applications

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What role do high-strength graphite molds play during vacuum hot pressing? Enhance Precision in CuAlMn Composites

- What roles do graphite molds play during vacuum hot pressing of Al-Sc alloys? Ensure Precision & Purity

- What is the role of graphite molds during the hot pressing of LSLBO ceramics? Essential for High-Density Electrolytes

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity