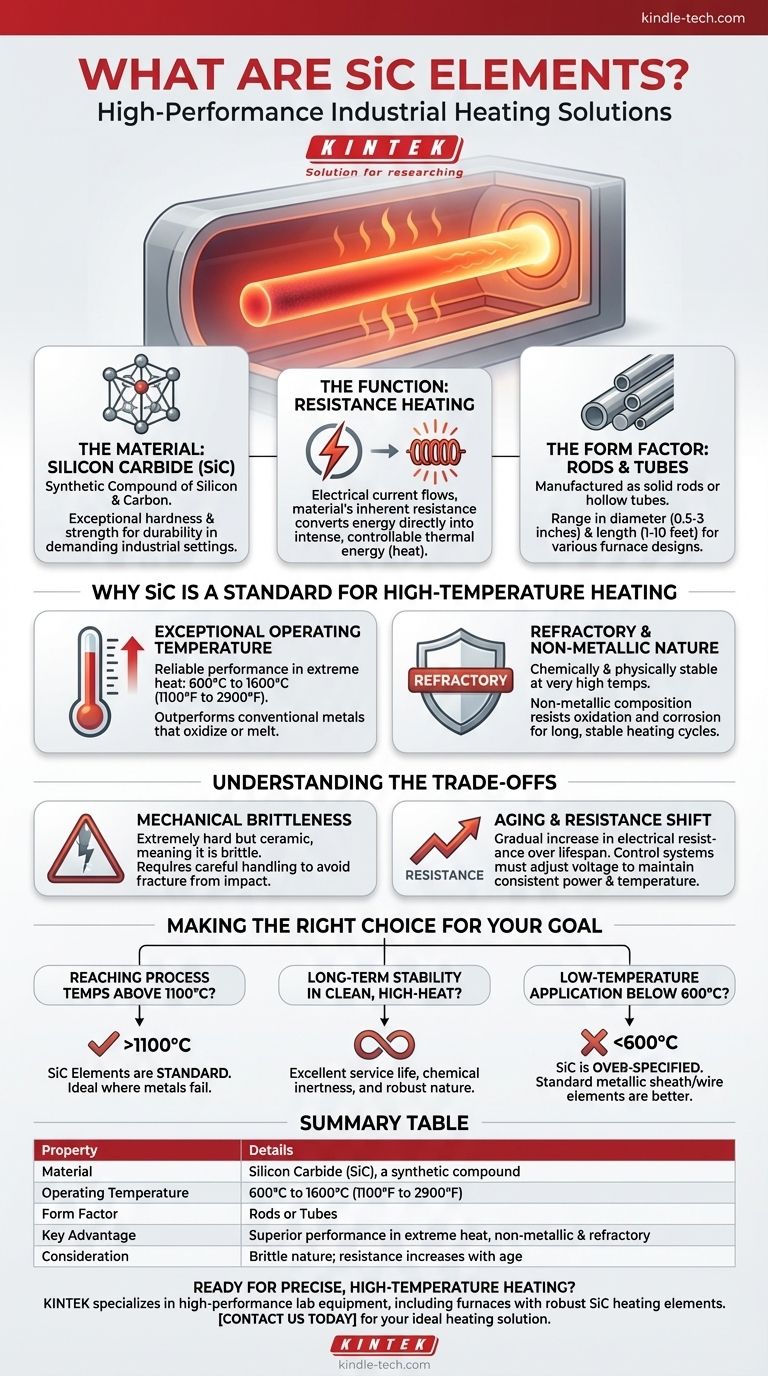

At its core, a Silicon Carbide (SiC) element is a high-performance heating component used in industrial furnaces and kilns. It is a non-metallic, electrically resistant product made from a hard compound of silicon and carbon. Typically formed into rods or tubes, these elements generate intense heat when electricity is passed through them, allowing them to operate reliably in extreme temperature environments.

A SiC element is the solution for electric heating applications that demand temperatures far beyond the limits of traditional metallic elements. Its primary function is to convert electrical energy into stable, high-level heat, operating effectively from 600°C up to 1600°C (1100°F to 2900°F).

The Fundamental Properties of SiC Elements

The Material: Silicon Carbide

Silicon Carbide (SiC), also known by the trade name Carborundum, is a synthetic chemical compound containing silicon and carbon.

Its molecular structure makes it exceptionally hard and strong, a key reason for its durability in demanding industrial settings.

The Function: Resistance Heating

SiC elements work on the principle of electrical resistance. When an electric current flows through the element, the material's inherent resistance impedes the flow of that electricity.

This opposition converts the electrical energy directly into thermal energy, or heat, in a highly efficient and controllable manner.

The Form Factor: Rods and Tubes

To suit various furnace designs, SiC elements are most commonly manufactured as solid rods or hollow tubes.

These shapes can range in diameter from half an inch to over three inches, with lengths varying from one to ten feet, enabling their use in both small laboratory furnaces and large industrial production lines.

Why SiC is a Standard for High-Temperature Heating

Exceptional Operating Temperature

The primary advantage of SiC elements is their ability to perform in extreme heat. They operate reliably within a temperature range of 600°C to 1600°C.

At these temperatures, most conventional metallic heating elements would quickly oxidize, deform, or melt.

Refractory and Non-Metallic Nature

SiC is a refractory material, meaning it is chemically and physically stable at very high temperatures.

Because it is non-metallic, it does not suffer from the same high-temperature corrosion or oxidation that limits the lifespan and performance of metal alloys. This makes it ideal for applications requiring long, stable heating cycles.

Understanding the Trade-offs

Mechanical Brittleness

While SiC is extremely hard and strong under compression, it is also a ceramic material and therefore brittle.

The elements must be handled with care during installation and maintenance, as they can be fractured by mechanical shock or impact.

Aging and Resistance Shift

Over their operational lifespan, SiC elements experience a gradual increase in electrical resistance.

This "aging" process is a natural characteristic of the material. Control systems must be able to compensate for this change by adjusting the voltage to maintain consistent power output and temperature.

Making the Right Choice for Your Goal

- If your primary focus is reaching process temperatures above 1100°C (2000°F): SiC elements are a standard and necessary choice, as they operate where conventional metallic options would fail.

- If your primary focus is long-term stability in a clean, high-heat environment: The chemical inertness and robust nature of SiC provide excellent service life and predictable performance.

- If your primary focus is a low-temperature application below 600°C (1100°F): SiC elements are generally over-specified and not cost-effective; standard metallic sheath or wire elements are a better fit.

Ultimately, SiC elements provide a robust and reliable solution for achieving precise, high-level heat in demanding industrial applications.

Summary Table:

| Property | Details |

|---|---|

| Material | Silicon Carbide (SiC), a synthetic compound |

| Operating Temperature | 600°C to 1600°C (1100°F to 2900°F) |

| Form Factor | Rods or Tubes |

| Key Advantage | Superior performance in extreme heat, non-metallic & refractory |

| Consideration | Brittle nature; resistance increases with age |

Ready to achieve precise, high-temperature heating for your lab or industrial process? KINTEK specializes in high-performance lab equipment, including furnaces with robust SiC heating elements. Our experts can help you select the ideal heating solution for your specific application, ensuring reliability and efficiency. Contact us today to discuss your needs and discover the KINTEK advantage!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance