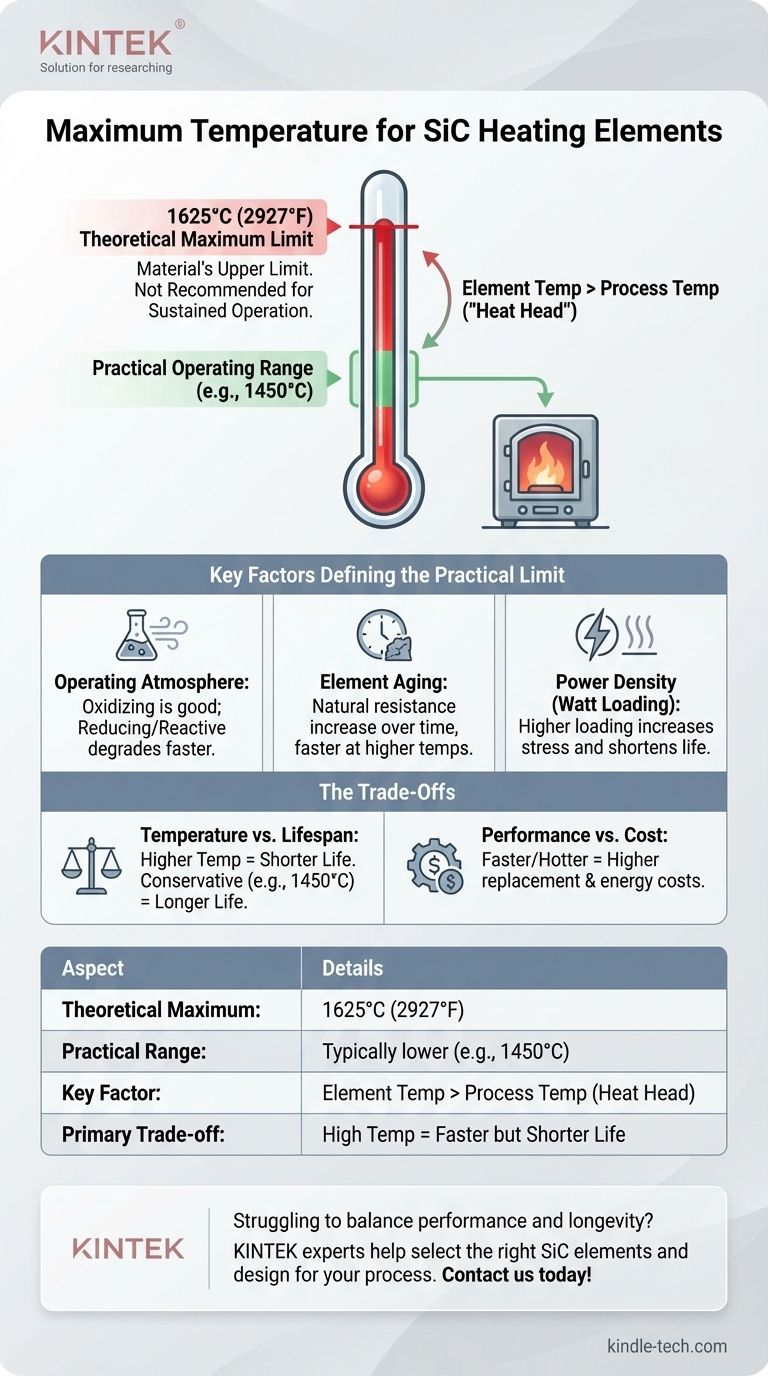

The maximum temperature for a Silicon Carbide (SiC) heating element is 1625°C (2927°F). However, this number represents the material's upper limit, not a typical or recommended operating temperature for a process. In practice, SiC elements are often used at lower temperatures to ensure a reasonable service life and process stability.

Understanding the true limit of a SiC element is not about a single number. It's about recognizing the crucial difference between the maximum temperature the element material can withstand and the sustainable process temperature your application requires.

Element Temperature vs. Process Temperature

The most critical concept to grasp is that the heating element must always be significantly hotter than the chamber or product it is heating. This temperature difference is what drives heat transfer into your process.

The "Heat Head" Requirement

To heat a furnace chamber to 1400°C, the element's surface may need to be 1500°C or higher. This temperature delta, sometimes called the "heat head," is essential for effective heating.

Why This Gap Matters

A larger temperature gap results in faster heat-up times. However, it also forces the element to operate closer to its physical limits, which accelerates aging and reduces its operational lifespan.

Key Factors That Define the Practical Limit

The theoretical maximum temperature is conditioned by several real-world variables. The actual temperature you can or should run is almost always lower than the 1625°C peak.

Operating Atmosphere

The type of atmosphere inside the furnace has a significant impact on element life. Oxidizing atmospheres are generally suitable, but certain reducing or reactive atmospheres can degrade the SiC material more rapidly, especially at extreme temperatures.

Element Aging

Over time and with use, SiC elements experience a gradual increase in electrical resistance. This aging process is a natural characteristic of the material and happens much faster at higher operating temperatures.

Power Density (Watt Loading)

How much power you push through the element for its surface area is called watt loading. Higher watt loading increases the element's temperature but also places more thermal and electrical stress on it, shortening its life.

Understanding the Trade-offs

Choosing an operating temperature is an engineering decision that balances performance against longevity and cost. There is no single "best" temperature; there is only the best temperature for your specific goal.

Temperature vs. Lifespan

This is the primary trade-off. Running an element closer to its maximum rated temperature of 1625°C will drastically reduce its service life compared to operating it at a more conservative temperature, such as 1450°C.

Performance vs. Cost

Achieving higher process temperatures or faster cycle times often requires running elements hotter. This improved performance comes at the direct cost of more frequent element replacement and higher energy consumption to compensate for element aging.

Making the Right Choice for Your Process

Your ideal operating temperature depends entirely on your operational priorities. A well-designed system considers these factors from the start.

- If your primary focus is maximizing element life and process stability: Operate your elements well below the maximum limit, aiming for a process temperature that allows for a moderate heat head.

- If your primary focus is achieving the highest possible process temperature or rapid heating: You can operate closer to the 1625°C element limit, but you must design the system to handle and expect a significantly shorter element lifespan.

Ultimately, selecting the right operating point is about making an informed decision that aligns with your specific production goals and budget.

Summary Table:

| Aspect | Details |

|---|---|

| Theoretical Maximum | 1625°C (2927°F) |

| Practical Operating Range | Typically lower, e.g., 1450°C for longer life |

| Key Factor | Element temperature must be higher than process temperature ("Heat Head") |

| Primary Trade-off | Higher temperature = Faster performance but shorter element lifespan |

| Critical Influences | Operating atmosphere, element aging, and power density (watt loading) |

Struggling to balance high-temperature performance with equipment longevity in your lab? KINTEK specializes in high-temperature lab equipment and consumables. Our experts can help you select the right SiC heating elements and design a furnace system that perfectly aligns with your process goals—whether your priority is maximum temperature, speed, or extended element life. Contact our team today for a personalized consultation and ensure your lab operates at peak efficiency.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Double Plate Heating Press Mold for Lab

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace