In a scientific context, sieving is a fundamental mechanical process used to separate and classify granular materials based on their particle size. It is widely employed in laboratory, quality control, and research settings to perform particle size analysis, grade materials into specific size fractions, and measure the impurity content of powders, granules, and even solids suspended in liquids.

The true purpose of sieving goes beyond simple separation. It is a critical tool for ensuring consistency and predictability, because a particle's size directly dictates its physical and chemical properties. By controlling size, you control how a material will behave and perform in its final application.

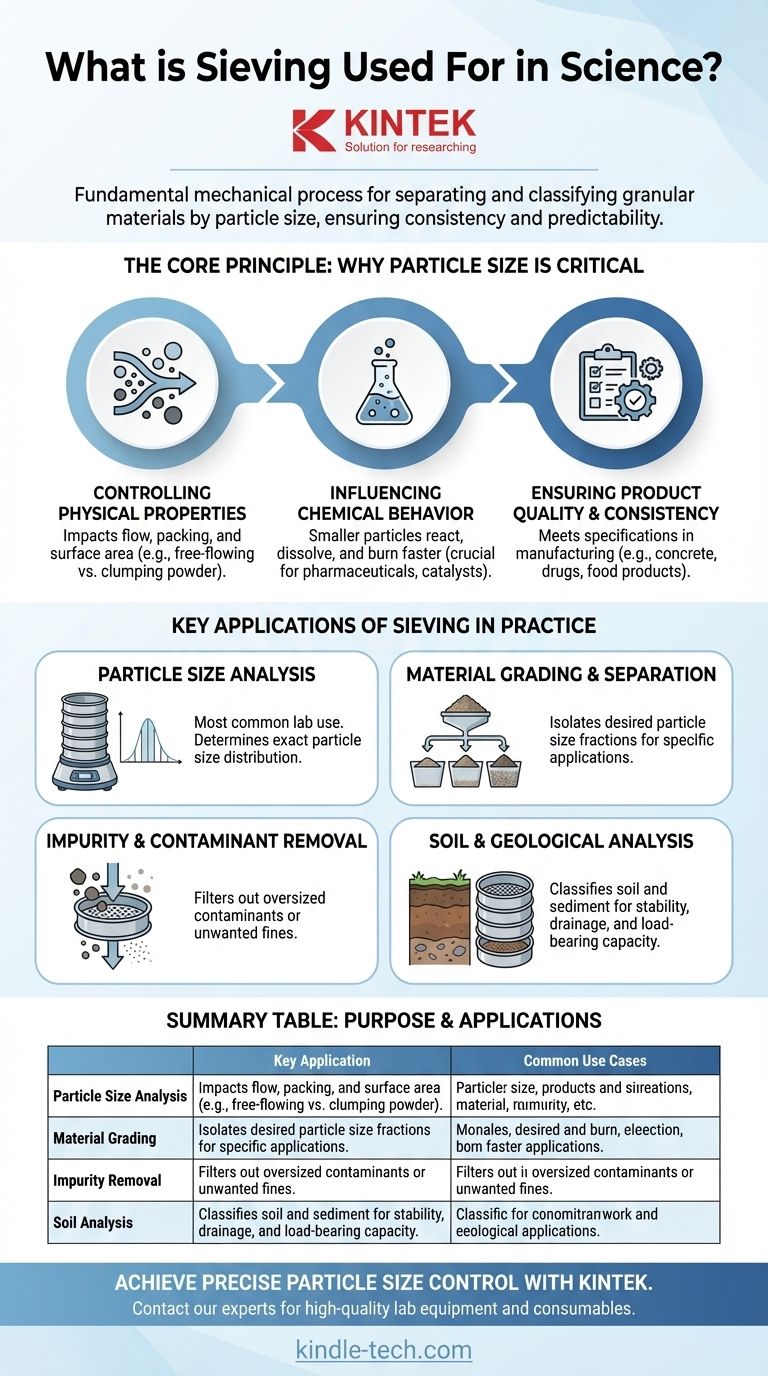

The Core Principle: Why Particle Size is Critical

Understanding the size distribution within a sample is essential because size directly influences a material's behavior. This is the "why" behind the process.

Controlling Physical Properties

A particle's size impacts its bulk characteristics, such as how it flows, packs together, and its overall surface area.

For example, a coarse, granular powder will flow freely from a hopper, while a very fine powder might clump and stick, causing blockages in a manufacturing process.

Influencing Chemical Behavior

Smaller particles have a much larger surface-area-to-volume ratio than larger particles.

This means a given mass of fine powder will react faster, dissolve more quickly, and burn more rapidly than the same mass of coarse granules. This is a crucial factor in pharmaceuticals, catalysts, and fuel development.

Ensuring Product Quality and Consistency

In manufacturing, the final product's performance often depends on a precise particle size distribution.

Whether producing concrete, formulating a drug, or making a food product, sieving is used as a primary quality control check to ensure the ingredients and final product meet required specifications.

Key Applications of Sieving in Practice

Sieving is applied in several distinct ways to achieve different scientific and industrial goals.

Particle Size Analysis

This is the most common laboratory use. A sample is placed on top of a stack of analytical sieves with progressively smaller mesh openings.

The stack is mechanically shaken, allowing particles to fall through until they are retained by a sieve they cannot pass. By weighing the material on each sieve, you can determine the exact particle size distribution of the sample.

Material Grading and Separation

In production settings, sieving is used to separate a bulk material into different size ranges, or "fractions."

This is done to isolate the desired particle size for a specific application, such as separating fine sand from coarse aggregate for use in specialized concrete mixes.

Impurity and Contaminant Removal

Sieving acts as a simple and effective filter. It can be used to remove oversized contaminants from a raw material or to remove unwanted fine dust (fines) from a granulated final product.

Soil and Geological Analysis

In civil engineering and geology, sieving is a standard method for classifying soil and sediment. Analyzing the distribution of sand, silt, and gravel is critical for determining a soil's stability, drainage, and load-bearing capacity.

Understanding the Trade-offs and Limitations

While powerful, sieving is not a perfect or universal solution. An expert understands its boundaries.

Ineffective for Very Fine Particles

Mechanical sieving has a practical lower limit, typically around 20 to 40 micrometers. For nanoparticles or very fine powders (sub-sieve range), other methods like laser diffraction or air classification are necessary.

The Influence of Particle Shape

Sieving fundamentally measures a particle's second-smallest dimension. Elongated or flat particles (like needles or flakes) can pass through mesh openings end-on or sideways.

This can lead to a misrepresentation of the true particle size distribution if the sample is not composed of roughly spherical particles.

Risk of Material Degradation

The agitation required for sieving can sometimes cause fragile particles to break down, a process known as attrition. This can artificially create more fine particles, skewing the very analysis you are trying to perform.

Applying This to Your Goal

Your specific use of sieving will depend on your objective.

- If your primary focus is quality control: You will likely use one or two key sieves to verify that a material meets a pre-defined size specification, often as a simple pass/fail test.

- If your primary focus is research and development: You will perform a full analysis with a stacked set of sieves to build a complete particle size distribution curve and understand how it impacts performance.

- If your primary focus is material preparation: You will use sieving on a larger scale to separate a bulk material into distinct size fractions needed for a formulation or manufacturing process.

Ultimately, sieving provides the foundational data needed to control a material's physical behavior and guarantee its performance in any application.

Summary Table:

| Purpose | Key Application | Common Use Cases |

|---|---|---|

| Particle Size Analysis | Determine size distribution | Quality control, R&D, material characterization |

| Material Grading | Separate into size fractions | Preparing specific particle sizes for formulations |

| Impurity Removal | Filter contaminants | Purifying raw materials or final products |

| Soil Analysis | Classify soil types | Geology, civil engineering, agriculture |

Achieve precise particle size control with the right equipment from KINTEK.

Whether your goal is rigorous quality control, detailed R&D analysis, or efficient material preparation, having reliable sieving equipment is fundamental. KINTEK specializes in high-quality lab equipment and consumables, providing the tools you need to ensure material consistency and performance.

Contact our experts today to discuss your specific application and find the perfect sieving solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research