At its core, ceramic sintering is a high-temperature manufacturing process that transforms a compacted powder into a solid, dense, and incredibly strong object. By applying intense heat and often pressure, individual ceramic particles are fused together, dramatically reducing internal porosity and creating a unified, non-porous structure without ever melting the material itself.

Sintering is not simply a baking process; it is a controlled microscopic transformation. It closes the gaps between raw material particles, fundamentally altering the ceramic's internal structure to unlock its signature properties of extreme hardness, durability, and resistance.

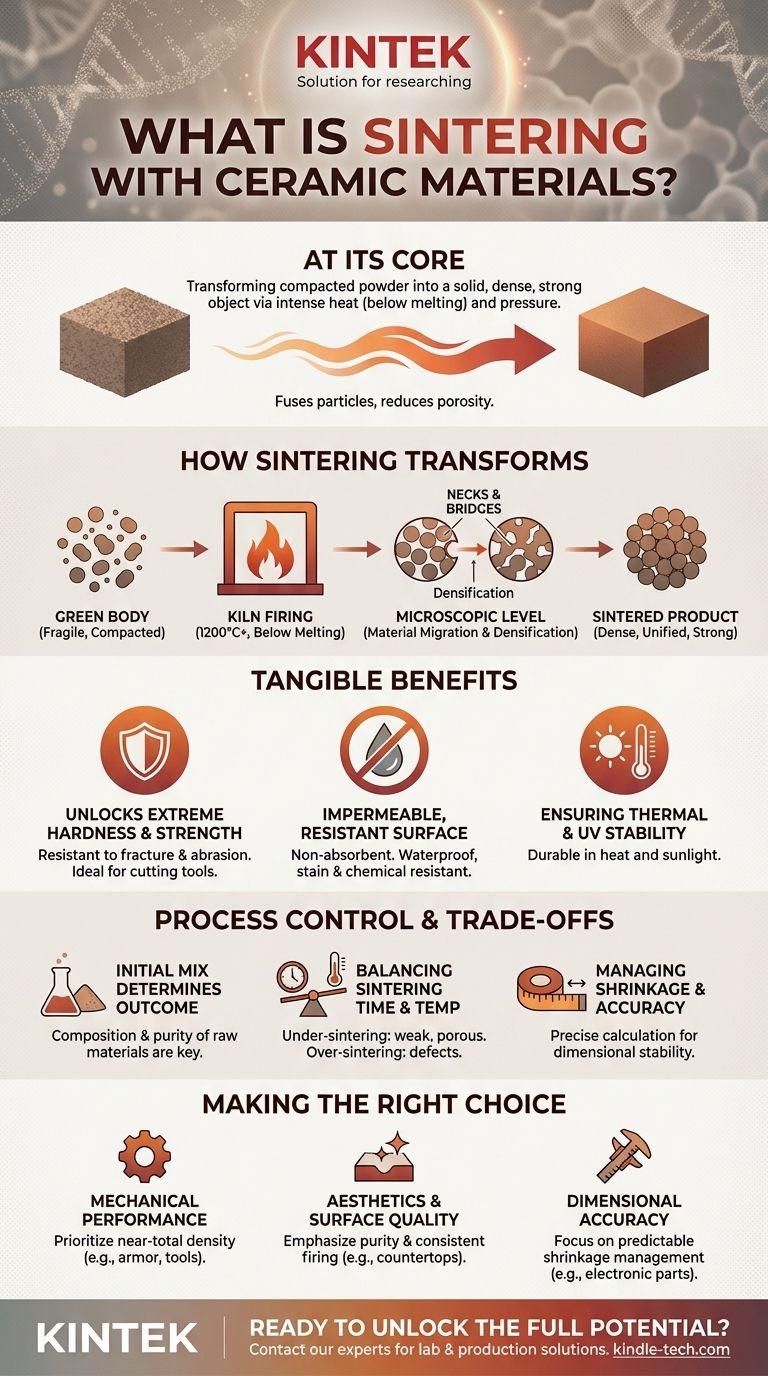

How Sintering Fundamentally Transforms Ceramic Powder

Sintering is the critical step that converts a fragile, compacted shape into a high-performance technical material. The transformation happens on a microscopic, atomic level.

From a "Green Body" to a Solid Mass

The process begins with a carefully selected mix of natural raw materials like clay, silica, feldspar, and mineral pigments. This powder is pressed under extreme force into a desired shape, known as a "green body." This initial form is chalky and fragile, held together only by compaction and binders.

The Role of Extreme Heat

The green body is then fired in a kiln at temperatures often exceeding 1200°C (2200°F). Crucially, this temperature is below the material's melting point. The goal is not to liquefy the ceramic, but to excite its atoms enough to trigger diffusion and bonding.

What Happens at the Microscopic Level

At these high temperatures, material migration occurs. Atoms move from the individual particles to form "necks" or bridges between them. As these bridges grow, the particles pull closer together, and the empty spaces (pores) between them shrink and are gradually eliminated. This process of densification is what gives the final product its strength.

The Tangible Benefits of a Sintered Structure

The dense, unified microstructure created during sintering is directly responsible for the remarkable performance characteristics of these materials.

Unlocking Extreme Hardness and Strength

By eliminating porosity, sintering creates a solid structure that is highly resistant to fracture and abrasion. For technical ceramics like zirconia, sintering also triggers a phase change in its crystalline structure, transforming it into an exceptionally hard state suitable for cutting tools and dental implants.

Creating an Impermeable, Resistant Surface

The lack of pores makes the final surface non-absorbent. This is why sintered ceramic is waterproof and highly resistant to stains, chemicals, and graffiti. There are simply no voids for liquids or contaminants to penetrate.

Ensuring Thermal and UV Stability

A material that has been forged at 1200°C is inherently stable at everyday temperatures. Sintered ceramics do not degrade under heat from a hot pan or from prolonged exposure to the sun's UV rays, making them exceptionally durable for both indoor and outdoor applications.

Understanding the Trade-offs and Process Control

Achieving a perfect sintered product is a precise science. The final properties are not guaranteed; they are the result of meticulous control over the entire process.

The Initial Mix Determines the Outcome

The final characteristics—strength, color, and chemical stability—are largely determined by the composition of the initial powder mix. The selection and purity of the raw materials like quartz, clay, and feldspars are the foundation for the final product's performance.

Balancing Sintering Time and Temperature

The goal is maximum densification without causing defects. Under-sintering (too low temperature or too short time) results in a porous, weak part. Over-sintering can cause abnormal grain growth, which paradoxically can reduce the material's strength and toughness.

Managing Shrinkage and Dimensional Accuracy

As the pores are eliminated, the entire component shrinks significantly. This shrinkage must be precisely calculated and accounted for when designing the initial "green body" mold. Uncontrolled sintering can lead to warped or dimensionally inaccurate parts, a critical failure for precision engineering components.

Making the Right Choice for Your Application

Understanding the principles of sintering allows you to specify materials that are fit for your specific purpose.

- If your primary focus is mechanical performance (e.g., cutting tools, armor): Prioritize materials that achieve near-total density through precise control of temperature and pressure.

- If your primary focus is aesthetics and surface quality (e.g., countertops, flooring): Emphasize the purity of the raw mineral mix and a consistent firing process to ensure color uniformity and a defect-free surface.

- If your primary focus is dimensional accuracy (e.g., electronic insulators, engineering parts): Focus on a manufacturer's ability to predictably manage shrinkage by standardizing powder compaction and heating cycles.

Mastering this process is how raw, natural minerals are transformed into some of the highest-performing materials available today.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Goal | Transform compacted powder into a solid, dense object without melting. |

| Typical Temperature | Often exceeds 1200°C (2200°F). |

| Primary Benefit | Creates a non-porous, unified structure for extreme hardness and durability. |

| Critical Factor | Meticulous control of time, temperature, and initial powder mix. |

| Common Challenge | Precise management of shrinkage for dimensional accuracy. |

Ready to unlock the full potential of ceramic materials for your lab or production needs?

At KINTEK, we specialize in providing the high-performance lab equipment and expert support necessary for precise thermal processes like sintering. Whether you are developing cutting tools, dental implants, or advanced technical components, our solutions help you achieve the perfect balance of density, strength, and dimensional accuracy.

Contact our experts today to discuss how we can support your material science projects with reliable equipment and consumables tailored to your specific ceramic sintering requirements.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability