In essence, molybdenum’s primary advantage is its exceptional ability to maintain strength and structural integrity at extremely high temperatures, far beyond the limits of common metals and alloys. This unique thermal resistance, combined with its relative affordability compared to other refractory metals, makes it a critical material for demanding industrial and aerospace applications.

Molybdenum's true value lies in its balance: it offers a rare combination of high-temperature strength, a high melting point, and reasonable cost, making it the go-to material for structural components in vacuum furnaces, lighting, and electronics manufacturing.

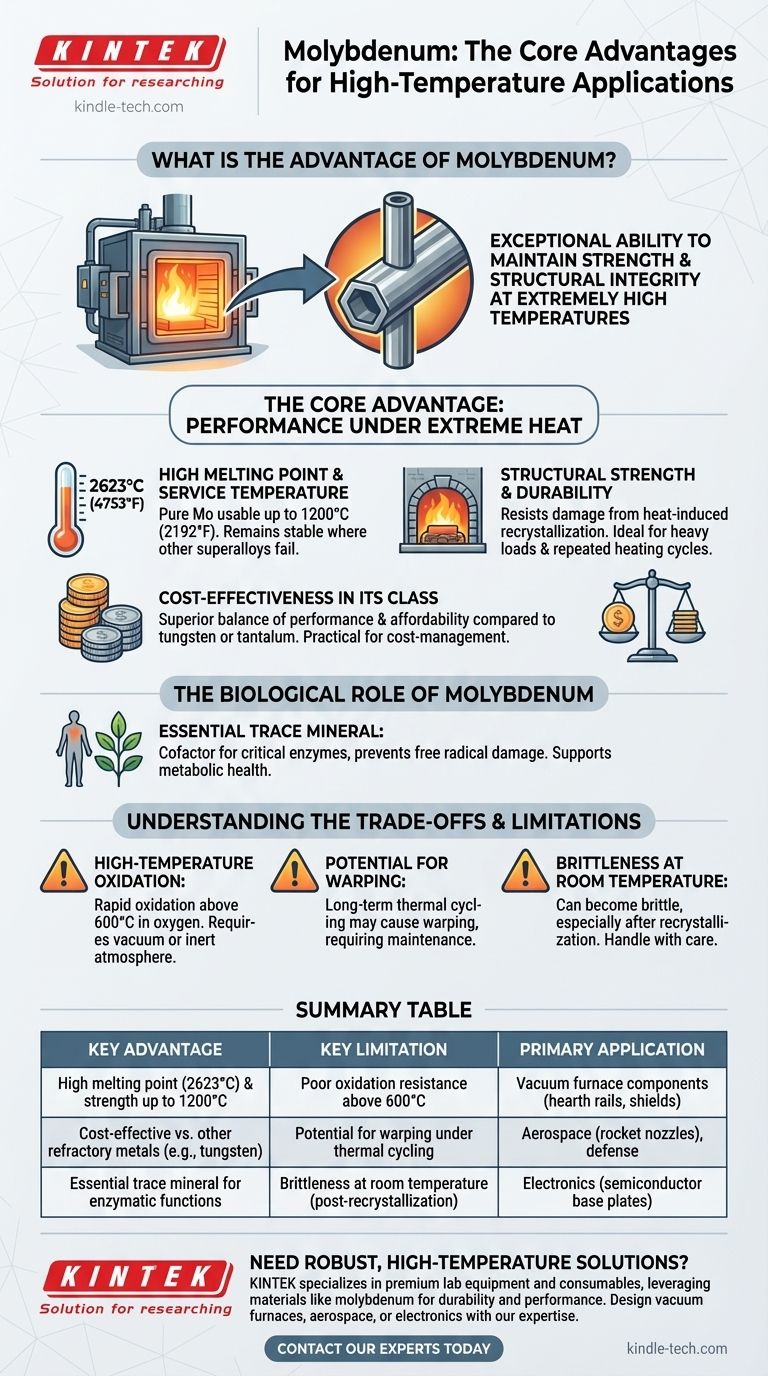

The Core Advantage: Performance Under Extreme Heat

Molybdenum belongs to a class of materials known as refractory metals, which are defined by their extraordinary resistance to heat and wear. This is its most significant and widely leveraged characteristic.

High Melting Point and Service Temperature

Pure molybdenum can be used in applications up to 1200°C (2192°F) without significant risk of recrystallization, a process that can alter a metal's structural properties.

Its high melting point of 2623°C (4753°F) ensures it remains solid and stable in environments where steel and other superalloys would fail.

Structural Strength and Durability

Even in thick sections, molybdenum components are not easily damaged by the heat-induced process of recrystallization.

This makes it an ideal material for furnace components like hearth rails and supports, which must endure repeated, intense heating and cooling cycles while bearing heavy loads.

Cost-Effectiveness in its Class

While not inexpensive in absolute terms, molybdenum offers a superior balance of performance and affordability when compared to other refractory metals like tungsten or tantalum.

This makes it a practical, high-performance choice for industries that need to manage costs without sacrificing thermal resilience.

The Biological Role of Molybdenum

Beyond its industrial applications, molybdenum is also an essential trace mineral required for human, animal, and plant life.

An Essential Trace Mineral

In the body, molybdenum acts as a cofactor for critical enzymes. This function is vital for processing sulfites and preventing the buildup of harmful substances.

Its role in enzymatic reactions also contributes to the body's ability to prevent damage from free radicals, which are unstable molecules that can cause cellular harm.

Supporting Key Bodily Functions

Sufficient levels of molybdenum are necessary for the body to function correctly. The references suggest it plays a part in processes like managing arthritis and balancing male hormones, highlighting its importance in our overall metabolic health.

Understanding the Trade-offs and Limitations

No material is perfect. To use molybdenum effectively, you must understand its specific vulnerabilities.

High-Temperature Oxidation

Molybdenum's primary weakness is its poor resistance to oxidation at temperatures above 600°C (1112°F). In the presence of oxygen, it rapidly forms a volatile oxide, leading to material loss.

For this reason, molybdenum components are almost always used in a vacuum or a protective, inert gas atmosphere for high-temperature applications.

Potential for Warping

Components subjected to long-term thermal cycling, such as furnace hearth rails, can eventually warp over time.

This may require periodic maintenance, such as hot-straightening, to restore the component's original shape and ensure proper function.

Brittleness at Room Temperature

While strong at high temperatures, molybdenum can become brittle at room temperature, especially after it has been fully recrystallized through use. This "room-temperature brittleness" means components must be handled with care during maintenance and installation to avoid fracture.

How to Apply This to Your Goal

Your decision to use or consider molybdenum depends entirely on your primary objective.

- If your primary focus is building high-temperature equipment: Molybdenum is an excellent choice for structural parts like heating elements, shields, and fixtures inside vacuum or inert-atmosphere furnaces.

- If your primary focus is aerospace or defense: Its high strength-to-weight ratio at elevated temperatures makes it suitable for rocket nozzles and other components exposed to extreme heat.

- If your primary focus is electronics manufacturing: Molybdenum's thermal expansion properties are similar to silicon, making it a valuable material for semiconductor base plates.

- If your primary focus is health and nutrition: Recognize molybdenum as an essential mineral obtained through a balanced diet; deficiencies are very rare and typically do not require special consideration.

Ultimately, molybdenum is the material of choice when you need reliable structural performance in a high-heat, controlled-atmosphere environment.

Summary Table:

| Key Advantage | Key Limitation | Primary Application |

|---|---|---|

| High melting point (2623°C) & strength up to 1200°C | Poor oxidation resistance above 600°C | Vacuum furnace components (hearth rails, shields) |

| Cost-effective vs. other refractory metals (e.g., tungsten) | Potential for warping under thermal cycling | Aerospace (rocket nozzles), defense |

| Essential trace mineral for enzymatic functions | Brittleness at room temperature (post-recrystallization) | Electronics (semiconductor base plates) |

Need robust, high-temperature solutions for your lab or production line? KINTEK specializes in premium lab equipment and consumables, leveraging materials like molybdenum to ensure durability and performance in demanding environments. Whether you're designing vacuum furnaces, aerospace components, or electronics, our expertise can help you achieve superior results. Contact our experts today to discuss how we can support your specific application!

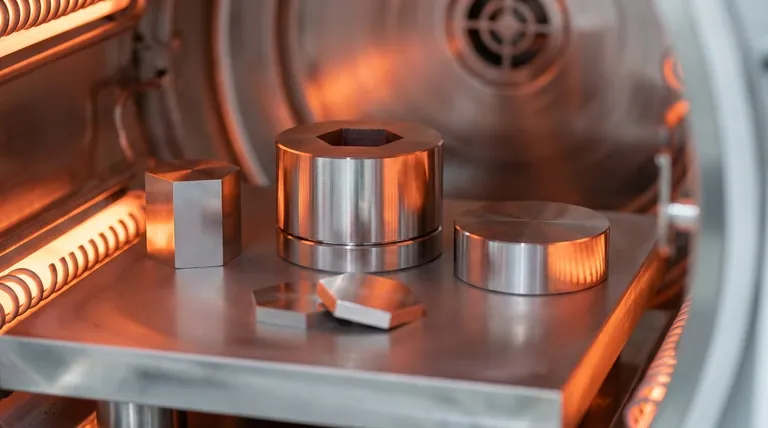

Visual Guide

Related Products

- Polygon Press Mold for Lab

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Boron Nitride (BN) Ceramic Plate

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

People Also Ask

- What industry uses tungsten? Leveraging Extreme Heat and Hardness for Industrial Applications

- Which metal works best as a heating element? Choose the Right Alloy for Your Temperature & Environment

- What is the crystal structure of MoSi2? Unlocking Its High-Temperature Performance

- Is tungsten used in heating elements? Unlocking Extreme Heat for Demanding Applications

- Why is it necessary to use a silica-sheathed platinum thermocouple in Hubnerite chlorination? Get Precise Kinetic Data

- How are tubular heaters made? The Science Behind Durable & Efficient Heating Elements

- What are the 5 different kinds of temperature sensing devices? Find the Right Tool for Your Application

- Can tungsten be used as a heating element? Unlocking Extreme Heat for High-Temperature Applications