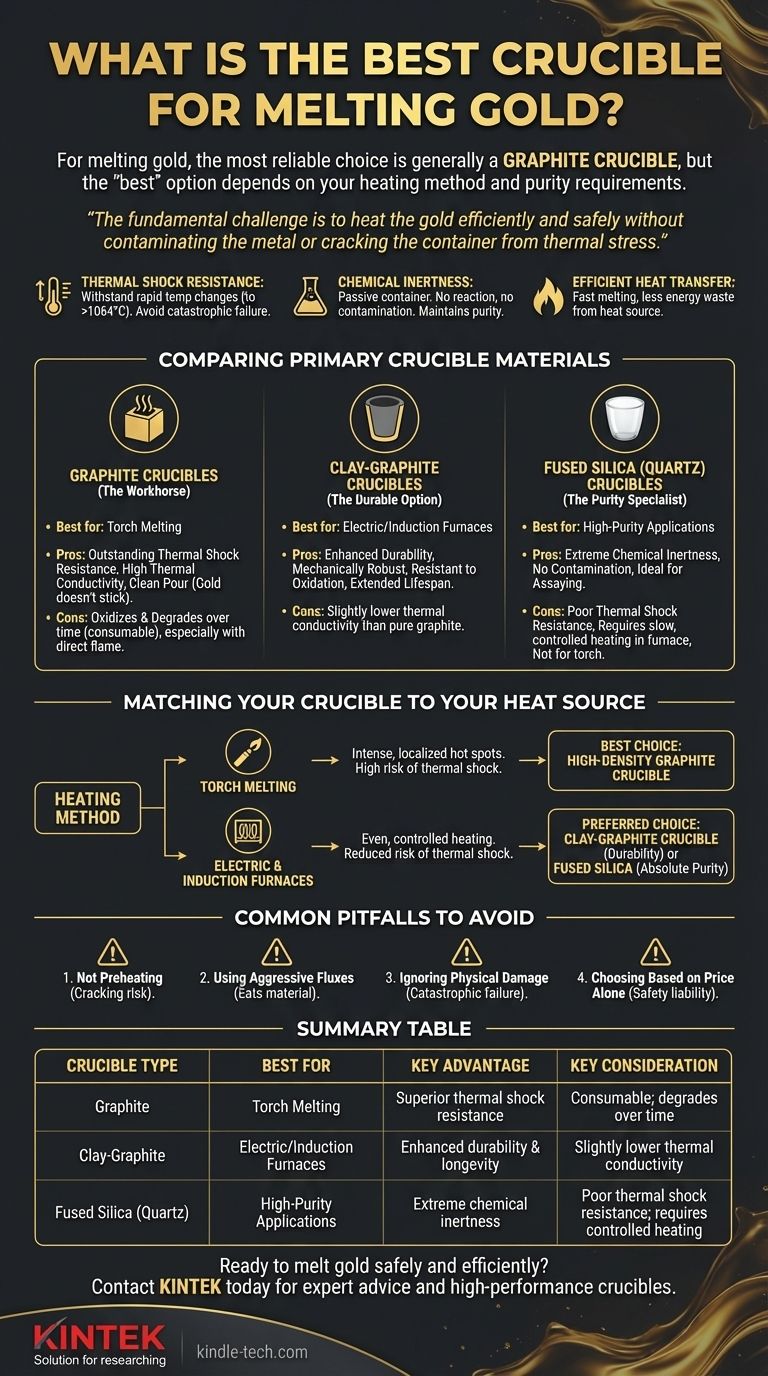

For melting gold, the most reliable and widely used choice is a graphite crucible. Its superior thermal conductivity and excellent resistance to thermal shock make it the standard for both hobbyists and professionals. While graphite is the best all-around option, clay-graphite composites offer enhanced durability for furnace use, and fused silica is preferred for applications demanding the highest purity.

The "best" crucible is not a single product but a function of your heating method and purity requirements. The fundamental challenge is to heat the gold efficiently and safely without contaminating the metal or cracking the container from thermal stress.

Why Crucible Selection is Critical

Choosing the right crucible is a matter of safety, efficiency, and final product quality. The material must withstand extreme conditions without failing or compromising the gold.

Resisting Thermal Shock

A crucible endures immense stress when heated from room temperature to over 1064°C (1948°F), the melting point of gold. Thermal shock is the cracking that occurs from rapid, uneven temperature changes. A material with poor resistance can fail catastrophically.

Ensuring Chemical Inertness

The crucible must be a passive container. It cannot react with, dissolve into, or otherwise contaminate the molten gold. This is essential for maintaining the purity and value of the metal.

Conducting Heat Efficiently

The material must transfer heat from your source—be it a torch or a furnace coil—to the metal inside. Efficient heat transfer means faster melting times and less wasted fuel or energy.

Comparing the Primary Crucible Materials

Each crucible material offers a unique balance of properties. Understanding their strengths and weaknesses is key to making an informed decision.

Graphite Crucibles (The Workhorse)

These are made from high-purity, high-density graphite. They are the go-to choice for most gold melting applications.

Their primary advantage is outstanding thermal shock resistance and high thermal conductivity. Gold also does not "wet" or stick to graphite, making for a clean pour.

The main drawback is that graphite oxidizes and degrades over time, especially when exposed to a direct torch flame. They are a consumable item that will eventually need replacement.

Clay-Graphite Crucibles (The Durable Option)

This is a composite material that blends graphite with ceramic clays like silicon carbide. This combination enhances the crucible's physical strength and longevity.

They are more mechanically robust and resistant to oxidation than pure graphite, making them a favorite for use in electric and induction furnaces where they see frequent, repeated cycles.

Their thermal conductivity is slightly lower than pure graphite, but their extended lifespan often makes this a worthwhile trade-off.

Fused Silica (Quartz) Crucibles (The Purity Specialist)

Fused silica is a type of high-purity glass capable of withstanding extreme temperatures. Its surface is exceptionally smooth and non-porous.

Its key benefit is its extreme chemical inertness, which prevents any contamination of the melt. This makes it the ideal choice for assaying, scientific work, or melting specific high-purity alloys.

However, fused silica has poor thermal shock resistance compared to graphite. It must be heated and cooled slowly and evenly, making it unsuitable for direct torch heating and best used inside a controlled electric furnace.

Matching Your Crucible to Your Heat Source

The way you apply heat is the single most important factor in choosing your crucible.

For Torch Melting

Direct torch heating creates intense, localized hot spots, maximizing the risk of thermal shock.

A high-density graphite crucible is the best choice here. Its ability to withstand rapid and uneven temperature changes is paramount for safety and reliability when using a torch.

For Electric & Induction Furnaces

Furnaces provide a much more even and controlled heating environment, reducing the risk of thermal shock.

A clay-graphite crucible is often the preferred choice. Its durability and resistance to oxidation hold up well to the repeated cycles of furnace work. Fused silica is also an excellent option in a furnace if your priority is absolute purity.

Common Pitfalls to Avoid

Mistakes in crucible handling are common and can lead to equipment failure, lost metal, and significant safety hazards.

Mistake 1: Not Preheating the Crucible

Never place cold metal into a crucible and immediately hit it with high heat. This is a primary cause of cracking. Always preheat the crucible gently until it glows dull red before adding your gold.

Mistake 2: Using Aggressive Fluxes

Borax is the standard flux for melting gold and helps season a graphite crucible. However, overly aggressive or improper fluxes can slowly eat away at the crucible material, shortening its life.

Mistake 3: Ignoring Physical Damage

Inspect your crucible before every use. Even a small crack or chip can become a catastrophic failure point once it's filled with heavy, molten metal. Discard any damaged crucibles immediately.

Mistake 4: Choosing Based on Price Alone

A cheap, low-quality crucible is a liability. The risk of it failing, spilling molten gold, and creating a dangerous situation far outweighs any initial savings. Invest in a reputable brand for safety and peace of mind.

Making the Right Choice for Your Goal

Your specific objective determines the ideal crucible.

- If you are a hobbyist using a torch: Choose a high-density graphite crucible for its superior resistance to the intense, direct heat of a flame.

- If you are running a small-scale operation with an electric or induction furnace: A clay-graphite crucible offers the best balance of durability and performance for repeated use.

- If your primary focus is assaying or working with high-purity alloys: A fused silica (quartz) crucible is the necessary choice to prevent any potential contamination.

Selecting the correct crucible transforms gold melting from a risky task into a controlled and reliable process.

Summary Table:

| Crucible Type | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Graphite | Torch Melting | Superior thermal shock resistance | Consumable; degrades over time |

| Clay-Graphite | Electric/Induction Furnaces | Enhanced durability & longevity | Slightly lower thermal conductivity |

| Fused Silica (Quartz) | High-Purity Applications | Extreme chemical inertness | Poor thermal shock resistance; requires controlled heating |

Ready to melt gold safely and efficiently? The right crucible is critical for your success. At KINTEK, we specialize in high-performance lab equipment, including a full range of crucibles designed for precise metal melting. Whether you're a hobbyist or running a professional lab, our experts can help you select the perfect crucible for your specific heat source and purity requirements. Contact KINTEK today to ensure your gold melting process is safe, efficient, and contamination-free!

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Evaporation Crucible for Organic Matter

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- What is an industrial crucible? A Guide to High-Temperature Melting Vessels

- What are the advantages of a crucible furnace? Achieve Precision Melting for Labs & Small-Scale Production

- What makes high-purity alumina crucibles suitable for pack cementation? Optimize Coating Purity & Thermal Stability

- What is the best material to use for a crucible? Match Your Metal to the Perfect Crucible

- What is the primary purpose of using alumina crucibles for LLTO ceramics? Optimize Your High-Temperature Sintering

- Do I need different crucibles for different metals? Ensure Safety and Purity in Your Metal Melting

- Does crucible size matter? Optimize Your Melt for Efficiency, Quality, and Safety

- Why are silica boats or high-purity ceramic crucibles used for Ni-TiO2 sintering? Ensure Pure Catalyst Results