The "best" heat treatment for steel is the one that achieves the specific mechanical properties required for a part's final application. There is no single universal "best" process; instead, heat treatment is a precise tool used to make steel harder, softer, or more stable, depending entirely on the end goal and the type of steel being used.

The core principle of heat treatment is not to find a single "best" method, but to understand your objective. The correct process is a function of the desired outcome—whether that is extreme hardness for a cutting tool, ductility for a stamped part, or internal stability for a welded frame.

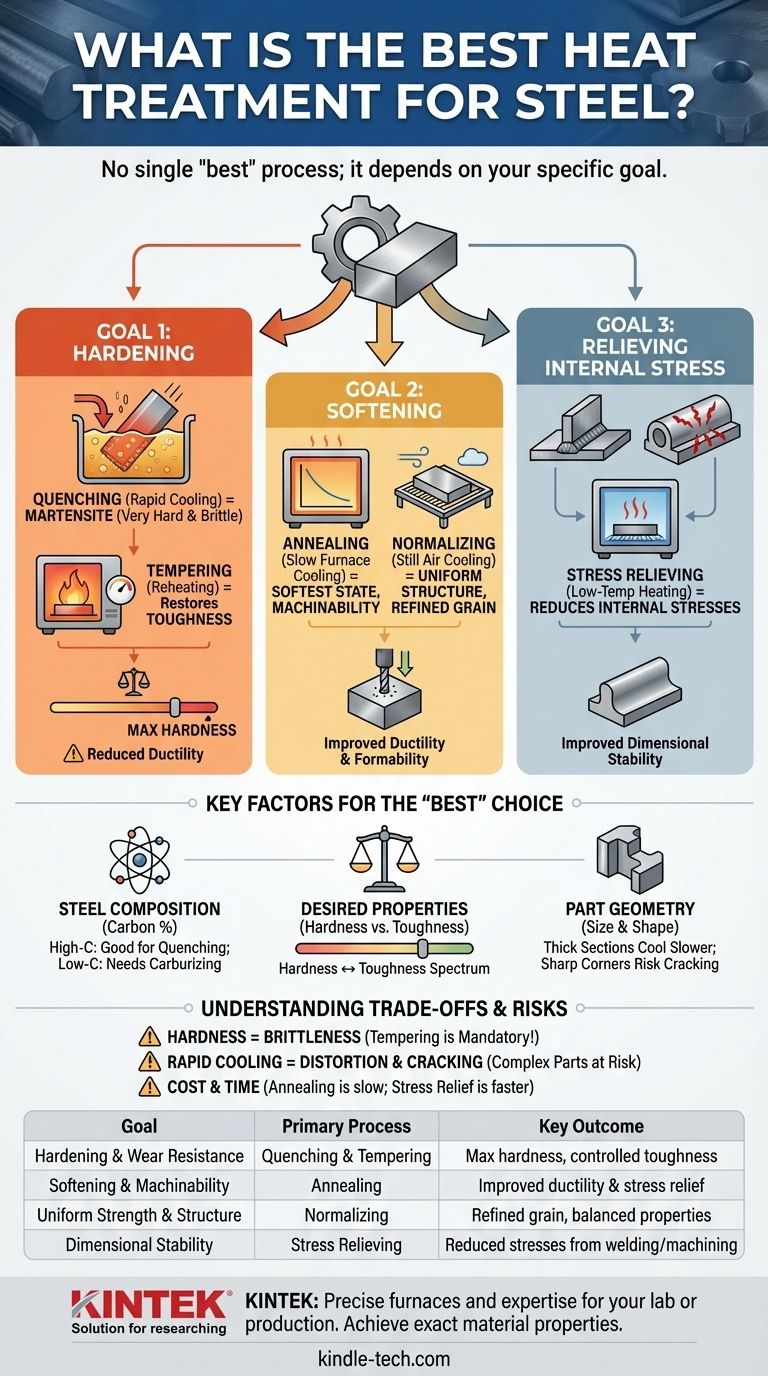

The Three Primary Goals of Heat Treatment

Think of heat treatment not as one process, but as a toolkit for modifying steel. The main processes can be grouped into three distinct categories based on their intended outcome.

Goal 1: Hardening the Steel

Hardening processes increase strength and wear resistance, but typically at the cost of reduced ductility.

Quenching is the cornerstone of hardening. It involves heating steel to a high temperature (into the austenitic range) and then cooling it with extreme rapidity.

This rapid cooling traps the carbon atoms, forming a very hard and brittle crystalline structure called martensite. The speed of the quench is critical, and different liquids (called quenchants) like water, brine, oil, or even forced air are used to control the cooling rate.

Tempering is an essential follow-up to quenching. A freshly quenched part is often too brittle for practical use. Tempering involves reheating the part to a lower, precisely controlled temperature to relieve some internal stress and restore a degree of toughness. The higher the tempering temperature, the softer and tougher the steel becomes.

Goal 2: Softening the Steel

In many cases, the goal is to make steel softer, more ductile, and easier to work with.

Annealing is the primary softening process. It involves heating the steel to a specific temperature, holding it there, and then cooling it very slowly, often by leaving it in the furnace to cool overnight.

This slow cooling allows the internal structure to reform into its softest possible state. Annealing is commonly used to improve machinability, prepare a part for extensive plastic forming (like stamping or drawing), or relieve stresses from prior work.

Normalizing is a related process where steel is heated to a similar temperature as annealing but is then cooled in still air. This faster cooling rate produces a harder and stronger material than annealing but a softer material than quenching. It is primarily used to refine the grain structure and create a more uniform, predictable material.

Goal 3: Relieving Internal Stress

Manufacturing processes like welding, machining, and cold forming introduce significant internal stresses into steel parts.

Stress Relieving is a low-temperature process designed to reduce these internal stresses without significantly altering the core mechanical properties. The part is heated to a temperature below its critical transformation point and held there long enough for the stresses to relax. This is crucial for improving dimensional stability and reducing the risk of premature failure.

Key Factors That Determine the "Best" Treatment

Choosing the right process depends on balancing three critical factors: the steel's chemistry, the desired final properties, and the part's physical shape.

Steel Composition (The Role of Carbon)

The amount of carbon in the steel is the single most important factor for hardening.

High-carbon steels (above ~0.40% C) respond very well to quenching and tempering, allowing them to achieve high hardness levels suitable for tools and springs.

Low-carbon steels (below ~0.30% C) have insufficient carbon to form significant martensite. They cannot be meaningfully hardened through conventional quenching. These steels often require surface-hardening methods like carburizing if a hard surface is needed.

Desired Mechanical Properties

You must define your priority. Are you optimizing for hardness or toughness? You can rarely have the maximum of both.

Think of it as a spectrum: a ceramic knife is extremely hard (high wear resistance) but shatters if dropped (brittle, low toughness). A soft copper wire is not hard at all but is very ductile and tough. Heat treatment allows you to place your steel at the precise point you need on this spectrum.

Part Geometry and Size

Thick sections cool much slower than thin sections during a quench. A treatment that successfully hardens a thin sheet may fail to harden the core of a thick block, a property known as hardenability. Complex shapes with sharp corners are also more prone to distortion and cracking during rapid cooling.

Understanding the Trade-offs

Every heat treatment process involves compromises. Understanding them is key to avoiding costly failures.

The Inherent Brittleness of Hardness

The pursuit of maximum hardness through quenching always creates extreme brittleness. For nearly all applications, tempering is not an optional step; it is a mandatory process to transform a brittle, unusable part into a strong and tough component.

The Risk of Distortion and Cracking

Rapid heating and cooling create massive thermal gradients and internal stresses. This can cause parts to warp out of tolerance or, in severe cases, crack during the quench. This risk is highest in complex parts, those with sharp internal corners, or those with dramatic changes in thickness.

Cost and Time Considerations

Processes are not equal in cost. A full anneal requires a furnace to be occupied for many hours during the slow cooling phase, consuming significant energy. Quenching and tempering requires careful handling and precise temperature control. A simple stress-relief cycle is often faster and less expensive.

Making the Right Choice for Your Application

Use your primary goal to guide your decision.

- If your primary focus is maximum hardness and wear resistance (tools, knives, bearings): Your process is Quenching to create hardness, immediately followed by a low-temperature Temper to reduce brittleness.

- If your primary focus is maximum ductility and machinability (parts for stamping, forming, or pre-machining): Your process is a full Anneal to achieve the softest possible state.

- If your primary focus is a uniform, refined structure with good strength and toughness (shafts, gears, forgings): Your process is Normalizing, or a Quench followed by a higher-temperature Temper.

- If your primary focus is dimensional stability after welding or heavy machining: Your process is a low-temperature Stress Relief cycle.

By defining your objective first, you can select the correct heat treatment to engineer the exact steel properties your project demands.

Summary Table:

| Goal | Primary Process | Key Outcome |

|---|---|---|

| Hardening & Wear Resistance | Quenching & Tempering | Maximum hardness with controlled toughness |

| Softening & Machinability | Annealing | Improved ductility and stress relief |

| Uniform Strength & Structure | Normalizing | Refined grain structure and balanced properties |

| Dimensional Stability | Stress Relieving | Reduced internal stresses from welding or machining |

Need precise heat treatment solutions for your lab or production? KINTEK specializes in lab equipment and consumables, providing reliable furnaces and expertise for annealing, quenching, tempering, and more. Let us help you achieve the exact material properties your project demands—contact our experts today for a tailored solution!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab