A furnace burnout cycle is not a standard operational feature; it is a critical warning sign that your heating system is malfunctioning. This destructive pattern occurs when the furnace repeatedly overheats, forces a safety shutdown to prevent damage or fire, and then attempts to restart once it cools, only to repeat the process.

The core issue behind a furnace burnout cycle is almost always a lack of sufficient airflow. Your furnace is generating heat faster than your system can distribute it, causing a safety switch to intervene. Ignoring this cycle will drastically shorten your furnace's lifespan and lead to catastrophic component failure.

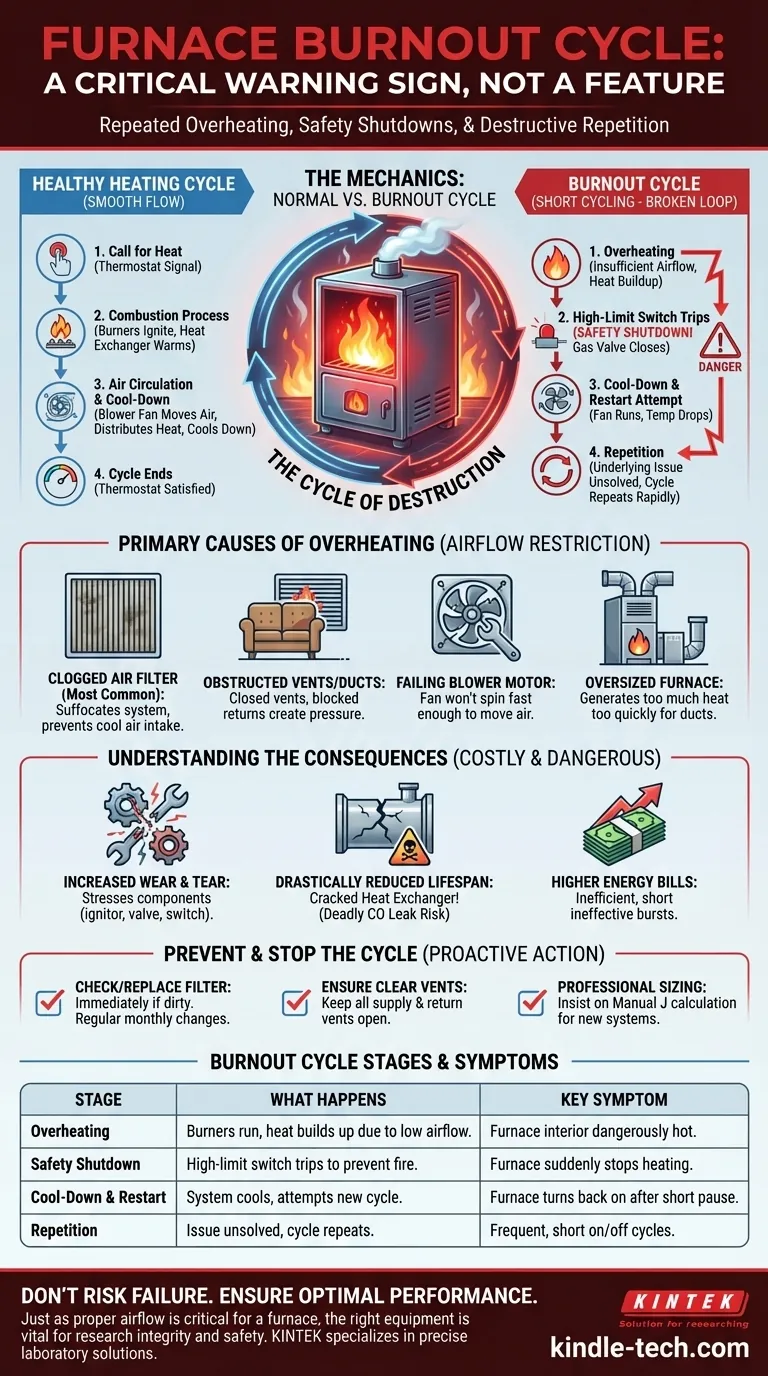

The Mechanics of a Normal Furnace Cycle

To understand what's going wrong, you first need to understand what a healthy heating cycle looks like.

The Call for Heat

It begins when your thermostat detects the room temperature has dropped below your setpoint. It sends an electrical signal to the furnace, initiating the heating sequence.

The Combustion Process

The furnace's ignitor glows hot, and the gas valve opens, allowing burners to ignite inside a sealed combustion chamber. This process heats a critical component called the heat exchanger.

Air Circulation and Cool-Down

After the heat exchanger reaches a specific temperature, the blower motor (fan) turns on. It pulls cool air from your home, passes it over the hot exterior of the heat exchanger, and then pushes the newly warmed air through your ductwork. Once the thermostat is satisfied, the burners shut off, and the blower continues to run for a short period to cool the heat exchanger down.

How the Burnout Cycle Disrupts Operation

A burnout cycle, also known as short cycling due to overheating, is a violent interruption of the normal sequence.

The Root Cause: Overheating

The problem begins when something prevents the system from moving enough air across the heat exchanger. The burners continue to run, but the heat has nowhere to go. This causes the internal temperature of the furnace to rise to dangerous levels.

The High-Limit Switch: A Safety Becomes a Symptom

Every furnace has a high-limit switch, a safety device that monitors the internal temperature. When it detects an unsafe temperature, it does its job by immediately shutting off the gas valve and burners to prevent a fire or a cracked heat exchanger.

The Destructive Repetition

The blower fan may continue to run to dissipate the intense residual heat. Once the temperature drops back to a safe level, the system will attempt to start a new heating cycle. However, because the underlying airflow problem hasn't been solved, the furnace will quickly overheat again, and the high-limit switch will trip again. This on-off-on-off pattern is the burnout cycle.

Diagnosing the Primary Causes of Overheating

The burnout cycle is a symptom. The true problem is almost always related to restricted airflow.

The Most Common Culprit: A Clogged Air Filter

A dirty, clogged air filter is the number one cause of furnace overheating. It effectively suffocates your system, preventing the blower from pulling in enough cool air to absorb the heat being generated.

Obstructed Vents and Ductwork

Closing too many vents in your home or blocking return air grilles with furniture has the same effect as a clogged filter. It creates too much pressure and restricts the airflow the system needs to function.

A Failing Blower Motor

The blower motor is the heart of your home's air circulation. If the motor is failing or its capacitor is weak, it won't spin the fan at the required speed to move enough air, leading to a rapid temperature buildup in the heat exchanger.

An Oversized Furnace

A less common but serious issue is a furnace that is too powerful for the home's ductwork. The unit generates an immense amount of heat so quickly that the ducts cannot possibly distribute it fast enough, causing the system to constantly overheat and shut itself down.

Understanding the Consequences

Allowing a burnout cycle to continue is not a viable option. The constant stress of extreme temperature swings creates significant problems.

Increased Wear and Tear on Components

Every time the limit switch trips, it places stress on the switch itself, the ignitor, the gas valve, and other control electronics. These components are not designed for such rapid, repeated cycling.

Drastically Reduced Furnace Lifespan

The most significant danger is to the heat exchanger. Repeatedly expanding and contracting under extreme temperatures can cause the metal to fatigue and crack. A cracked heat exchanger can leak deadly carbon monoxide into your home and will require a complete furnace replacement.

Higher Energy Bills

A furnace that is constantly starting and stopping cannot operate efficiently. Your energy consumption will increase significantly as the system struggles to heat your home in short, ineffective bursts.

How to Prevent and Stop the Burnout Cycle

You can take direct action to protect your heating system from this damaging condition.

- If you suspect a burnout cycle is happening now: Immediately check your air filter. If it's dirty, replace it with a clean one and see if the problem resolves. If not, turn the system off and call a qualified HVAC professional.

- If you want to prevent future issues: Change your furnace filter regularly (monthly for basic filters, or as recommended for thicker media filters). Also, ensure all supply and return air vents in your home are open and unobstructed.

- If you are replacing your system: Insist that your HVAC contractor perform a proper load calculation (Manual J) to ensure your new furnace is sized correctly for your home and its existing ductwork.

Proactive maintenance is the key to ensuring your furnace operates safely and efficiently for its entire intended lifespan.

Summary Table:

| Burnout Cycle Stage | What Happens | Key Symptom |

|---|---|---|

| Overheating | Burners run, but insufficient airflow causes heat buildup. | Furnace interior gets dangerously hot. |

| Safety Shutdown | High-limit switch trips, shutting off burners to prevent fire. | Furnace suddenly stops heating. |

| Cool-Down & Restart | System cools, then attempts a new cycle. | Furnace turns back on after a short pause. |

| Repetition | Underlying issue unsolved, cycle repeats. | Frequent, short on/off cycles. |

Is your furnace stuck in a burnout cycle? Don't risk a cracked heat exchanger or a system failure.

KINTEK specializes in the precise equipment and consumables that keep laboratories running safely and efficiently. Just as proper airflow is critical for a furnace, the right lab equipment is vital for your research integrity and safety.

Let our experts help you maintain optimal performance in your lab. Contact KINTEK today for reliable solutions tailored to your laboratory's unique needs.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of a muffle furnace in assessing NbTiVZr alloys? Test High-Temp Nuclear Durability

- What are the classification of refractory materials? A Guide to Chemical and Thermal Selection

- What is the difference between oven incubator and muffle furnace? Choose the Right Lab Heating Tool

- What is the use of muffle furnace in food laboratory? Essential for Accurate Nutritional Analysis & Quality Control

- What is the use of muffle furnace in pharmaceuticals? Essential for Purity & Quality Control