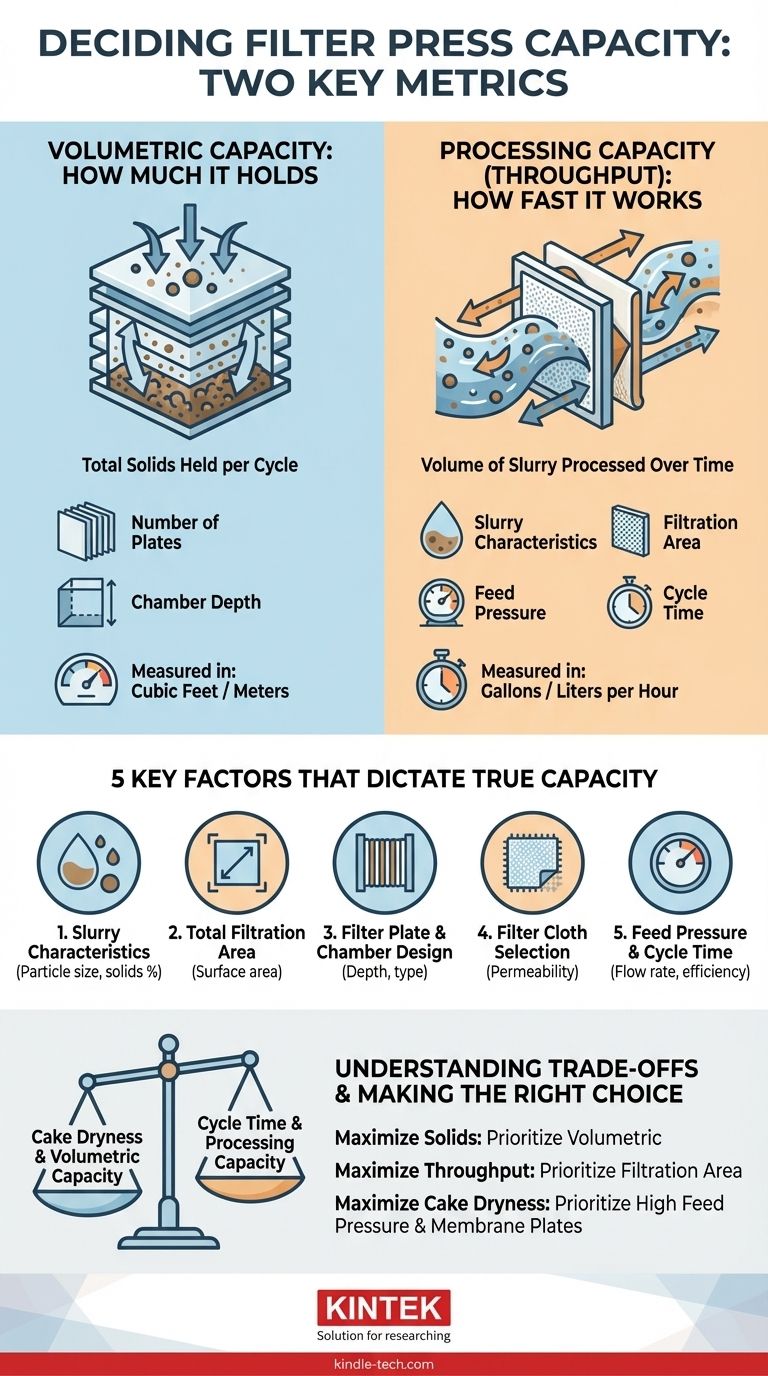

Stated simply, the capacity of a filter press is not a single number but is defined by two key metrics: its volumetric capacity (the total solids it can hold) and its processing capacity, or throughput (the volume of slurry it can process over time). Volumetric capacity is measured in cubic feet or meters, determined by the size and number of filter plates. Processing capacity is a rate, measured in gallons or liters per hour, and depends on a much wider range of variables.

A filter press's true capacity is not determined by its physical size alone. It is a dynamic outcome of the interplay between the press's design (chamber volume, filtration area) and the specific characteristics of the slurry being processed (solids concentration, particle size).

The Two Pillars of Filter Press Capacity

To correctly size a filter press, you must understand both of its capacity dimensions. One defines the batch size, and the other defines the operational speed.

Volumetric Capacity: How Much It Holds

This is the most straightforward metric. It represents the total internal volume of all the empty chambers between the filter plates.

This volume dictates the maximum amount of dewatered solids, or "filter cake," the press can hold in a single cycle. It is calculated based on the depth of the chambers and the number of plates in the press frame.

Processing Capacity (Throughput): How Fast It Works

This is a measure of rate—how quickly the press can separate a liquid from a solid. It is a far more complex metric because it is not static.

Throughput is influenced by the press itself, but it is heavily dependent on the nature of the material you are filtering. Two presses with identical volumetric capacity can have vastly different throughputs when processing different slurries.

Key Factors That Dictate True Capacity

A press's nameplate capacity is only a starting point. Real-world performance is governed by the following factors.

Slurry Characteristics

This is the most critical variable. The composition of the liquid-solid mixture you need to separate has the largest impact on processing speed. Key aspects include the percentage of solids, particle size and shape, and the compressibility of the solids.

Total Filtration Area

The total surface area of the filter cloth across all plates determines how much area is available for liquid to pass through. A larger filtration area generally allows for a higher flow rate and faster cycle times, directly boosting throughput.

Filter Plate and Chamber Design

The depth of the chamber in each filter plate affects both volumetric capacity and cycle time. Deeper chambers increase the volume of solids held per cycle but can sometimes result in wetter cakes or require longer dewatering times.

Filter Cloth Selection

The permeability of the filter cloth is crucial. An improperly chosen cloth can either let fine solids pass through or, more commonly, "blind" (clog) quickly, which dramatically reduces the filtration rate and brings operations to a halt.

Feed Pressure and Cycle Time

The pressure delivered by the feed pump directly impacts how quickly the liquid is forced through the filter media. The total cycle time—including filling, pressing, air blowing, and cake discharge—determines how many batches you can run in a day, defining the ultimate daily throughput.

Understanding the Trade-offs

Selecting and operating a filter press involves balancing competing priorities. Understanding these trade-offs is essential for optimizing your process.

Cake Dryness vs. Cycle Time

Achieving a very dry filter cake requires longer pressing times at high pressure. This increases the duration of each cycle, which in turn reduces the overall daily throughput. You must decide which is more important: maximum cake dryness or maximum processing speed.

Volumetric Capacity vs. Handling Difficulty

A press with very large chambers can hold more solids, reducing the labor required for cake discharge over a 24-hour period. However, for slurries that are difficult to dewater, shallower chambers often yield better results and more manageable cakes, even if it means more frequent cycles.

Capital Cost vs. Automation

Larger, fully automated presses with features like automatic plate shifters and cloth washers have a high initial cost but drastically reduce labor and can improve cycle time consistency. A smaller, manual press is cheaper upfront but will have a lower overall throughput due to slower, labor-intensive cake discharge.

Making the Right Choice for Your Goal

To determine the right filter press capacity, you must first define your primary operational goal. The "best" press is the one that aligns with your specific priority.

- If your primary focus is capturing a set amount of solids per day: You should prioritize volumetric capacity (cubic feet/meters) and ensure the press is large enough to handle your daily solids load in a reasonable number of cycles.

- If your primary focus is processing a high volume of slurry quickly: You should prioritize total filtration area (square feet/meters) and optimize pump pressure and slurry conditioning to maximize throughput.

- If your primary focus is achieving maximum cake dryness: You should prioritize a press capable of high feed pressures and consider specialized membrane filter plates, which can squeeze the cake at the end of a cycle.

Ultimately, defining your operational goals is the first and most critical step in correctly sizing a filter press for your application.

Summary Table:

| Capacity Metric | Definition | Key Influencing Factors |

|---|---|---|

| Volumetric Capacity | Total volume of solids held per cycle (cubic ft/m) | Number of plates, chamber depth |

| Processing Capacity (Throughput) | Volume of slurry processed per hour (gal/hr, L/hr) | Slurry characteristics, filtration area, feed pressure, cycle time |

Need to optimize your dewatering process? Choosing the right filter press is critical for efficiency and cost-effectiveness. At KINTEK, we specialize in lab equipment and consumables, providing tailored solutions for your specific slurry characteristics and throughput goals. Our experts can help you select the ideal press, filter plates, and cloth to maximize cake dryness and processing speed. Contact us today for a consultation and let KINTEK enhance your laboratory's filtration performance!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples