The correct post-treatment for a platinum disk electrode is a multi-step process focused on immediate cleaning and proper storage. After an experiment, you must promptly remove the electrode from the electrolyte, rinse it thoroughly with distilled or deionized water, and gently absorb any moisture with filter paper. The electrode should then be stored in a dry, clean environment, protected from physical damage.

The goal of post-experiment treatment is not just cleaning, but preservation. A consistent and careful procedure ensures your electrode's surface remains uncontaminated and electrochemically stable, which is the foundation for reproducible and accurate results in future experiments.

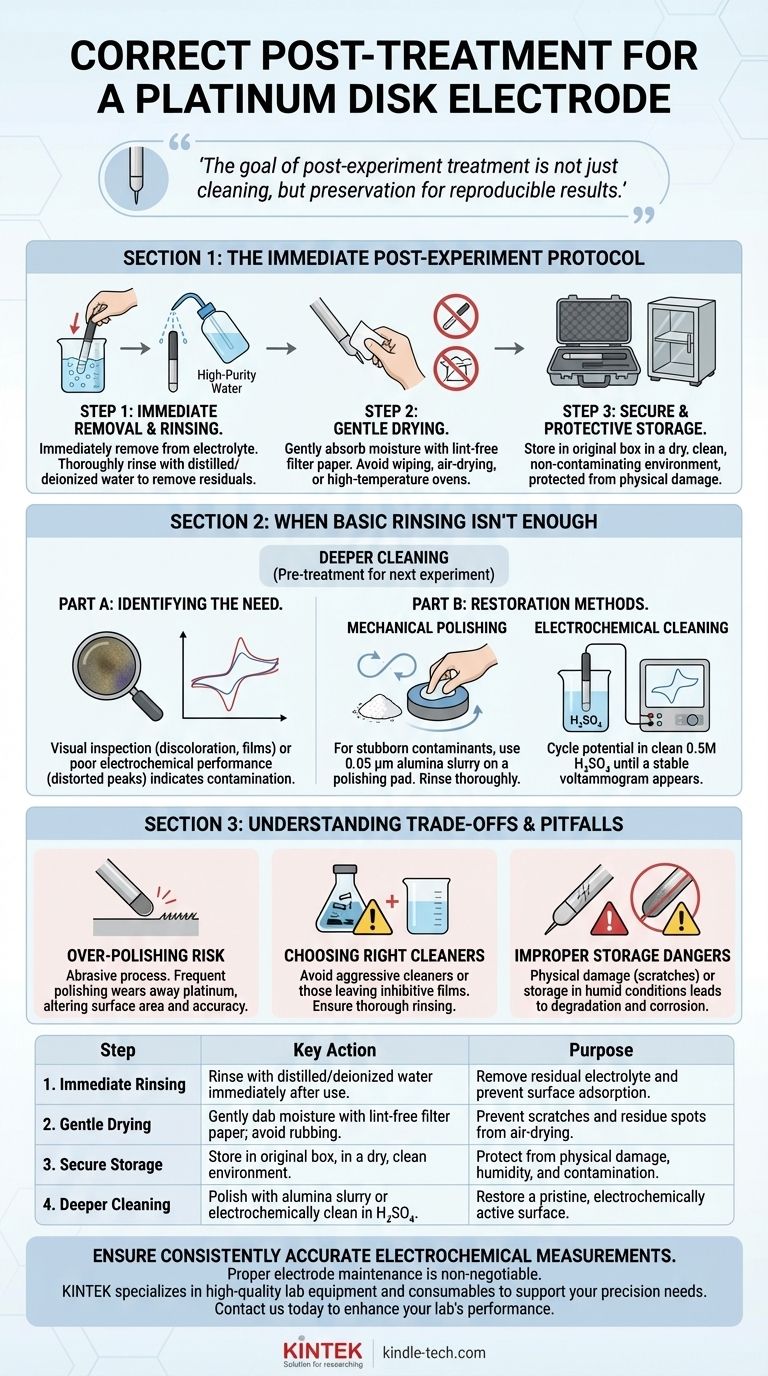

The Immediate Post-Experiment Protocol

A disciplined post-treatment routine is the first line of defense against electrode degradation and experimental drift. Each step is simple but serves a critical purpose in maintaining the integrity of the platinum surface.

Step 1: Immediate Removal and Rinsing

The electrode must be removed from the electrolyte immediately after the experiment concludes. This prevents further side reactions or the adsorption of species onto the platinum surface.

Rinse the electrode thoroughly using a stream of high-purity water, such as distilled or deionized water. This removes residual electrolyte salts and weakly adsorbed impurities. For experiments in non-aqueous solutions, a suitable solvent like ethanol may be used, followed by a final rinse with pure water.

Step 2: Gentle Drying

Surface moisture should be carefully absorbed using lint-free filter paper. Gently dab the electrode tip; do not wipe or rub, as this can scratch the polished surface or leave behind paper fibers.

Avoid air-drying, which can leave behind spots or residues from evaporated droplets. Similarly, do not use a high-temperature oven, as this can induce oxidation of the platinum surface.

Step 3: Secure and Protective Storage

Store the electrode in a dry, clean, and non-contaminating environment. Exposure to humidity, high temperatures, or even strong light can degrade the electrode over time.

The original storage box is ideal. These cases are designed to protect the fragile connection points and prevent the polished platinum disk from coming into contact with hard or abrasive surfaces. Storing it with the platinum surface facing upwards is a good practice.

When Basic Rinsing Isn't Enough

Sometimes, a simple water rinse is insufficient to restore the electrode. This is when post-treatment overlaps with the pre-treatment required for your next experiment. Recognizing the need for more intensive cleaning is a key skill.

Identifying the Need for Deeper Cleaning

Visually inspect the electrode surface before storage. If you see any discoloration, films, or a dull appearance, a deeper cleaning procedure is necessary before its next use.

Poor electrochemical performance, such as distorted or shifted peaks in a cyclic voltammogram, is a clear indicator that the surface is contaminated and requires reconditioning.

Mechanical Polishing

For stubborn surface contaminants, mechanical polishing is the most effective method. Create a slurry of 0.05 µm alumina powder on a polishing pad.

Gently polish the electrode in a figure-eight motion, then rinse it thoroughly with deionized water to remove all alumina particles. This process should restore a mirror-like finish.

Electrochemical Cleaning

As a final preparatory step before the next experiment, you can perform electrochemical cleaning. This involves cycling the electrode's potential in a clean electrolyte, typically 0.5M sulfuric acid (H₂SO₄).

You continue the scans until a stable, characteristic platinum voltammogram appears, which confirms the surface is clean and electrochemically active.

Understanding the Trade-offs and Pitfalls

While these procedures are standard, applying them incorrectly can do more harm than good. Understanding the limitations is crucial for extending the life of your electrode.

The Risk of Over-Polishing

Mechanical polishing is an abrasive process. While effective, frequent polishing will gradually wear away the platinum and can alter the surface roughness of the electrode.

This can change the electrode's effective surface area, impacting the accuracy of quantitative measurements. Polishing should only be performed when necessary, not as a routine step after every experiment.

Choosing the Right Cleaners

While dilute acids like nitric acid can be used for cleaning, they are aggressive. Always ensure any cleaning agent is thoroughly rinsed away, as residual chemicals will contaminate subsequent experiments.

Never use cleaners known to be corrosive to platinum or that could leave behind an inhibitive film on the surface.

The Dangers of Improper Storage

An improperly stored electrode is susceptible to both physical and chemical damage. A scratch on the disk surface creates an active site that changes the electrode's behavior.

Storing an electrode while it is still damp or in a humid environment can lead to the slow formation of oxide layers or corrosion at the seal between the platinum and the insulating body.

Making the Right Choice for Your Goal

Your post-treatment and pre-treatment strategy should match the demands of your work. The goal is to establish a known and reproducible surface state for every experiment.

- If your primary focus is routine testing in clean solutions: A thorough rinse with deionized water, gentle drying, and proper storage is typically sufficient after each run.

- If you observe a film or poor performance: Mechanical polishing with alumina powder is the necessary step to physically remove the contamination before the next use.

- If your primary focus is high-precision quantitative analysis: You must establish a pristine surface by performing the full pre-treatment cycle (polish, sonicate, and electrochemical cleaning) before every critical experiment.

A well-maintained electrode is the most critical variable you can control for achieving reliable electrochemical data.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Immediate Rinsing | Rinse with distilled/deionized water immediately after use. | Remove residual electrolyte and prevent surface adsorption. |

| 2. Gentle Drying | Dab moisture with lint-free filter paper; avoid rubbing. | Prevent scratches and residue spots from air-drying. |

| 3. Secure Storage | Store in original box, in a dry, clean environment. | Protect from physical damage, humidity, and contamination. |

| 4. Deeper Cleaning (if needed) | Polish with alumina slurry or electrochemically clean in H₂SO₄. | Restore a pristine, electrochemically active surface. |

Ensure your lab's electrochemical measurements are consistently accurate. Proper electrode maintenance is non-negotiable for reliable data. KINTEK specializes in high-quality lab equipment and consumables, including electrodes and cleaning supplies, to support your laboratory's precision needs. Let our experts help you select the right tools and establish best practices. Contact us today to discuss your specific requirements and enhance your lab's performance.

Visual Guide

Related Products

- Platinum Sheet Electrode for Battery Lab Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- How can a worn or scratched platinum disk electrode surface be restored? Achieve a Mirror Finish for Reliable Data

- What are the performance characteristics of platinum wire/rod electrodes? Unmatched Stability for Your Lab

- What is a common use for a platinum sheet electrode? As a Reliable Counter Electrode in Electrochemical Cells

- What are the functions of platinum sheet and Ag/AgCl electrodes in corrosion testing? Master Electrochemical Precision

- What can cause poisoning of a platinum disk electrode and how can it be prevented? Ensure Reliable Electrochemical Data