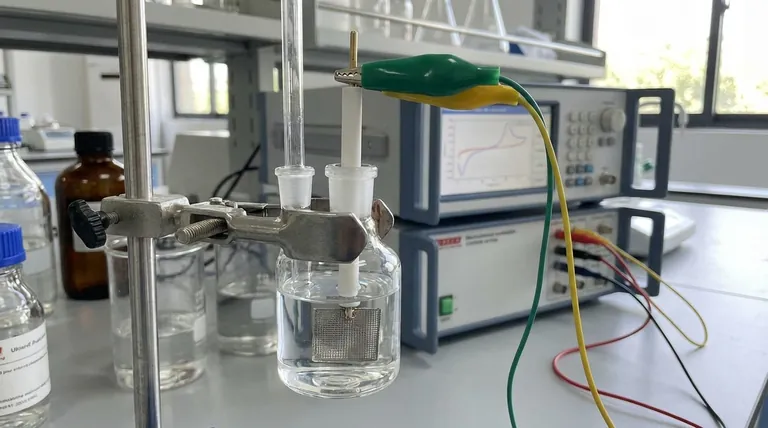

To correctly install a graphite electrode, you must first fix it securely within the electrolytic cell, ensuring the working surface is fully immersed in the electrolyte. Next, use conductive clips to connect it firmly to the appropriate terminal on your electrochemical workstation, paying close attention to the designated polarity to ensure the correct reaction occurs.

The reliability of your experimental results depends not just on making a connection, but on the quality and cleanliness of that connection. A stable mechanical setup, a clean electrode surface, and correct polarity are the foundational pillars of accurate electrochemical measurement.

The Principles of a Sound Electrode Setup

A proper installation goes beyond simply plugging in a wire. Each step is designed to eliminate variables that could compromise your data.

Ensuring Mechanical Stability

The electrode must be held firmly in place by a holder or clamp. Any movement during the experiment can change the immersion depth and alter the active surface area, introducing significant noise and inconsistency into your measurements.

Achieving Full Electrolyte Contact

The portion of the graphite intended for the reaction must be completely submerged in the solution. This ensures that the entire working surface is active and that the measured current is representative of the intended surface area.

Creating a Reliable Electrical Connection

Use clean, conductive clips (like alligator clips) to connect the top of the graphite rod to the workstation's lead wire. This connection must be firm and secure. A loose connection is a primary source of experimental failure, leading to an intermittent or open circuit.

The Critical Role of Polarity

Connecting the electrode to the wrong terminal on the potentiostat or power supply will invalidate your experiment.

Anode vs. Cathode

In electrochemistry, polarity dictates the reaction. One connection drives oxidation (anode), and the other drives reduction (cathode). Connecting your graphite electrode incorrectly will either drive the unintended reaction or prevent any reaction from occurring.

Connecting to the Workstation

Your electrochemical workstation will have clearly labeled terminals (e.g., Working, Counter, Reference). The graphite electrode, typically used as the working electrode, must be connected to the corresponding terminal for the instrument to control and measure the desired process accurately.

Common Pitfalls That Compromise Results

Even with a basic understanding, several common mistakes can lead to failed experiments and unreliable data.

The Problem of a Loose Connection

A connection that is not tight can vibrate or shift, causing dramatic fluctuations in resistance. This appears as high noise in your data or can cause the connection to fail entirely, resulting in an open circuit mid-experiment.

The Impact of a Contaminated Surface

The electrode surface is where the chemical reaction happens. Any residue, oils from handling, or leftover reactants from a previous experiment will interfere with the process, altering reaction kinetics and yielding inaccurate, non-repeatable results.

Electrode Care: The Key to Repeatable Data

Proper maintenance is not an afterthought; it is an integral part of the experimental procedure.

Preparing the Surface Before Use

For many applications, the electrode surface should be renewed before an experiment. This can be achieved by gently polishing it with a fine alumina powder slurry or sanding it with very fine-grit sandpaper, followed by a thorough rinse with deionized water.

Immediate Cleaning After Use

As soon as the experiment is complete, rinse the electrode thoroughly with deionized or ultrapure water. This removes the bulk of the electrolyte and prevents residual reactants from drying and hardening on the surface.

Handling Stubborn Residue

If water is insufficient, use an appropriate solvent like ethanol or acetone to remove organic contaminants. For more stubborn films, a light polish may be necessary.

Proper Drying and Storage

After cleaning, gently dry the electrode with a clean paper towel or a stream of compressed air. Store it in a dry, clean, and dust-free container to protect the surface from atmospheric contaminants.

How to Apply This to Your Experiment

Your specific focus will determine which aspect of the procedure requires the most attention.

- If your primary focus is quantitative analysis: Prioritize creating a fresh, reproducible electrode surface before every single measurement.

- If your primary focus is a long-duration experiment: Double-check the mechanical stability and the firmness of the electrical connection to prevent failures over time.

- If your primary focus is fundamental research: Always verify the correct polarity to ensure you are studying the intended electrochemical process.

Ultimately, mastering the setup and maintenance of your electrode is the first step toward generating trustworthy and publishable data.

Summary Table:

| Key Step | Purpose | Critical Detail |

|---|---|---|

| Mechanical Fixing | Prevent movement & noise | Use a stable clamp or holder |

| Full Immersion | Activate entire working surface | Submerge intended reaction area |

| Electrical Connection | Ensure circuit reliability | Use firm, clean alligator clips |

| Polarity Check | Drive the intended reaction | Connect to correct workstation terminal (e.g., Working Electrode) |

| Surface Preparation | Enable reproducible reactions | Polish and clean before use |

Achieve Publishable Electrochemical Data with KINTEK

Mastering your electrode setup is the foundation of reliable experimentation. KINTEK specializes in high-quality lab equipment and consumables, including electrochemical workstations, electrodes, and essential accessories, to support your research needs.

Let our expertise help you eliminate setup errors and ensure the accuracy of your results. Contact our technical specialists today to discuss your specific application and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Platinum Auxiliary Electrode for Laboratory Use

- Iridium Dioxide IrO2 for Water Electrolysis

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

People Also Ask

- Why is a platinum wire (PtW) counter electrode preferred for cathode LSV tests? Ensure High-Precision Research

- What are the technical advantages of using a spiral platinum wire? Optimize Your Electrochemical Precision

- What is the benefit of using a platinized platinum wire as a counter electrode? Optimize Operando Study Precision

- Why is platinum a good counter electrode? For Superior Chemical Inertness and Electron Transfer

- Why is a platinum electrode typically selected as the auxiliary or counter electrode? Unlock Precise Data Accuracy