Handling a platinum wire electrode requires meticulous care centered on three phases: gentle physical handling during use, immediate and thorough cleaning after use, and proper dry storage to prevent damage and contamination. Because the electrode's surface integrity is directly linked to the accuracy of your measurements, these steps are critical for obtaining reliable and repeatable results.

The core principle of handling a platinum wire electrode is to treat its surface as a pristine, active sensor. Every step, from inspection to storage, is designed to prevent physical damage and chemical contamination that would compromise its electrochemical performance and shorten its lifespan.

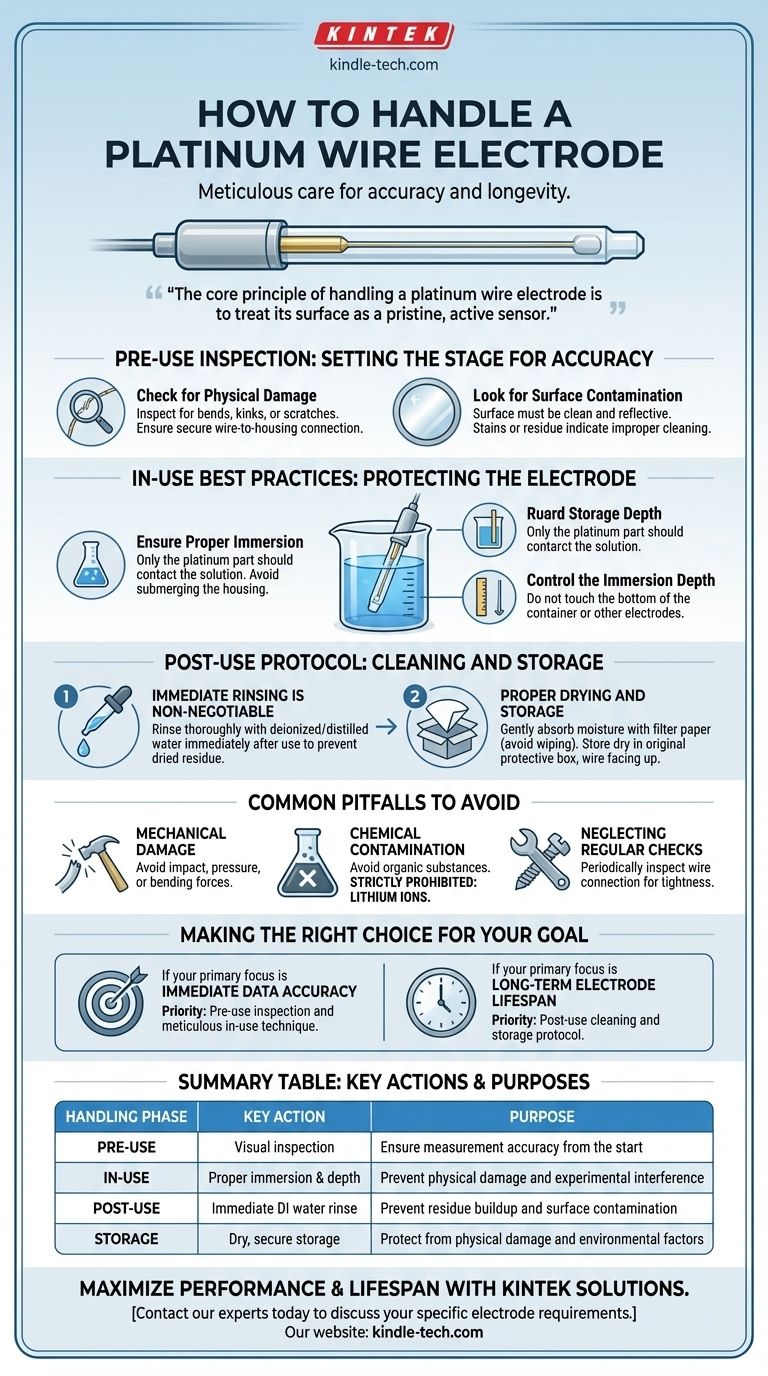

Pre-Use Inspection: Setting the Stage for Accuracy

Before any experiment, a quick visual inspection is your first line of defense against erroneous data. A compromised electrode will produce compromised results.

Check for Physical Damage

The platinum wire is soft and easily deformed. Look for any bends, kinks, or scratches on the wire itself.

Ensure the connection point between the wire and the housing is secure and shows no signs of loosening or corrosion.

Look for Surface Contamination

The surface should be clean and reflective. Any visible stains, discoloration, or residue from previous experiments indicates improper cleaning.

These contaminants can alter the electrochemical reactions, leading to inaccurate measurements. If contamination is present, the electrode requires cleaning before use.

In-Use Best Practices: Protecting the Electrode

During an experiment, your handling technique directly impacts both the electrode's integrity and the quality of your data.

Ensure Proper Immersion

Only the platinum part of the electrode should ever come into contact with the electrolyte solution.

Submerging other parts, such as the housing or connection point, can lead to corrosion and introduce contaminants into your experiment.

Control the Immersion Depth

Carefully control the depth of the wire within the electrolyte.

The electrode must not touch the bottom of the container or make contact with other electrodes in the cell, as this can cause physical damage and interfere with the measurement.

Post-Use Protocol: Cleaning and Storage

What you do immediately after an experiment is critical for the long-term health and performance of the electrode.

Immediate Rinsing is Non-Negotiable

As soon as the experiment is complete, remove the electrode from the electrolyte.

Immediately rinse the platinum wire thoroughly with deionized or distilled water. This prevents residual electrolyte from drying on the surface, which can be difficult to remove later.

Proper Drying and Storage

After rinsing, gently absorb any surface moisture with clean filter paper. Avoid wiping, which could bend the delicate wire.

Store the electrode in a clean, dry environment, preferably in its original protective box. This prevents accidental impact and protects the sensitive connection point. Storing it with the platinum wire facing upwards is an additional safeguard.

Common Pitfalls to Avoid

Mistakes in handling are often the primary cause of electrode failure and poor data quality. Understanding these common errors is key to prevention.

Mechanical Damage

The most common failure mode is physical damage. Never subject the electrode to impact, pressure, or bending forces. Treat it with the same care as delicate glassware.

Chemical Contamination

The platinum surface is easily fouled. Avoid all contact with organic substances unless they are part of the intended experiment.

Crucially, avoid any contact with lithium ions. Lithium is highly corrosive to platinum and its use with this type of electrode is strictly prohibited.

Neglecting Regular Checks

Over time, connections can loosen. Periodically inspect the wire connection to ensure it remains tight and provides good electrical conductivity. A loose connection is a hidden source of experimental noise and error.

Making the Right Choice for Your Goal

Your handling protocol should align directly with your primary objective, whether it's achieving the highest possible precision in a single experiment or ensuring the electrode lasts for many years.

- If your primary focus is immediate data accuracy: Your priority is the pre-use inspection and meticulous in-use technique. An un-inspected, improperly immersed electrode is the fastest way to generate unreliable results.

- If your primary focus is long-term electrode lifespan: Your priority is the post-use cleaning and storage protocol. Improper cleaning and storage are the leading causes of cumulative damage and performance degradation over time.

Ultimately, consistent and careful handling is the single most important factor in maximizing the value and reliability of your platinum wire electrode.

Summary Table:

| Handling Phase | Key Action | Purpose |

|---|---|---|

| Pre-Use | Visual inspection for damage/contamination | Ensure measurement accuracy from the start |

| In-Use | Proper immersion depth; avoid contact | Prevent physical damage and experimental interference |

| Post-Use | Immediate rinsing with distilled water | Prevent residue buildup and surface contamination |

| Storage | Dry, secure storage in original container | Protect from physical damage and environmental factors |

Maximize the performance and lifespan of your laboratory electrodes. Proper handling is crucial for reliable data. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools and expert support your laboratory needs to achieve precise results consistently.

Contact our experts today to discuss your specific electrode requirements and ensure your lab operates at peak efficiency.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Gold Disc Electrode

- Graphite Disc Rod and Sheet Electrode Electrochemical Graphite Electrode

People Also Ask

- What is the proper post-treatment procedure for a platinum sheet electrode? Ensure Long-Term Accuracy & Protect Your Investment

- What is the expected lifespan of a platinum sheet electrode? Maximize Your Electrode's Service Life

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- How should a platinum sheet electrode be pretreated before use? Ensure Accurate Electrochemical Measurements

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance