The correct procedure is to first disconnect all power, then sequentially remove the electrodes, auxiliary equipment, and finally the electrolytic cell. If hazardous materials are present, the cell must be cleaned of any residual liquid before it is removed from its stand to prevent spills and corrosion.

The post-experiment shutdown is not just a cleanup task; it is a critical safety protocol designed to protect both the operator and the equipment. The sequence of operations is deliberately structured to minimize electrical hazards, chemical exposure, and damage to sensitive components.

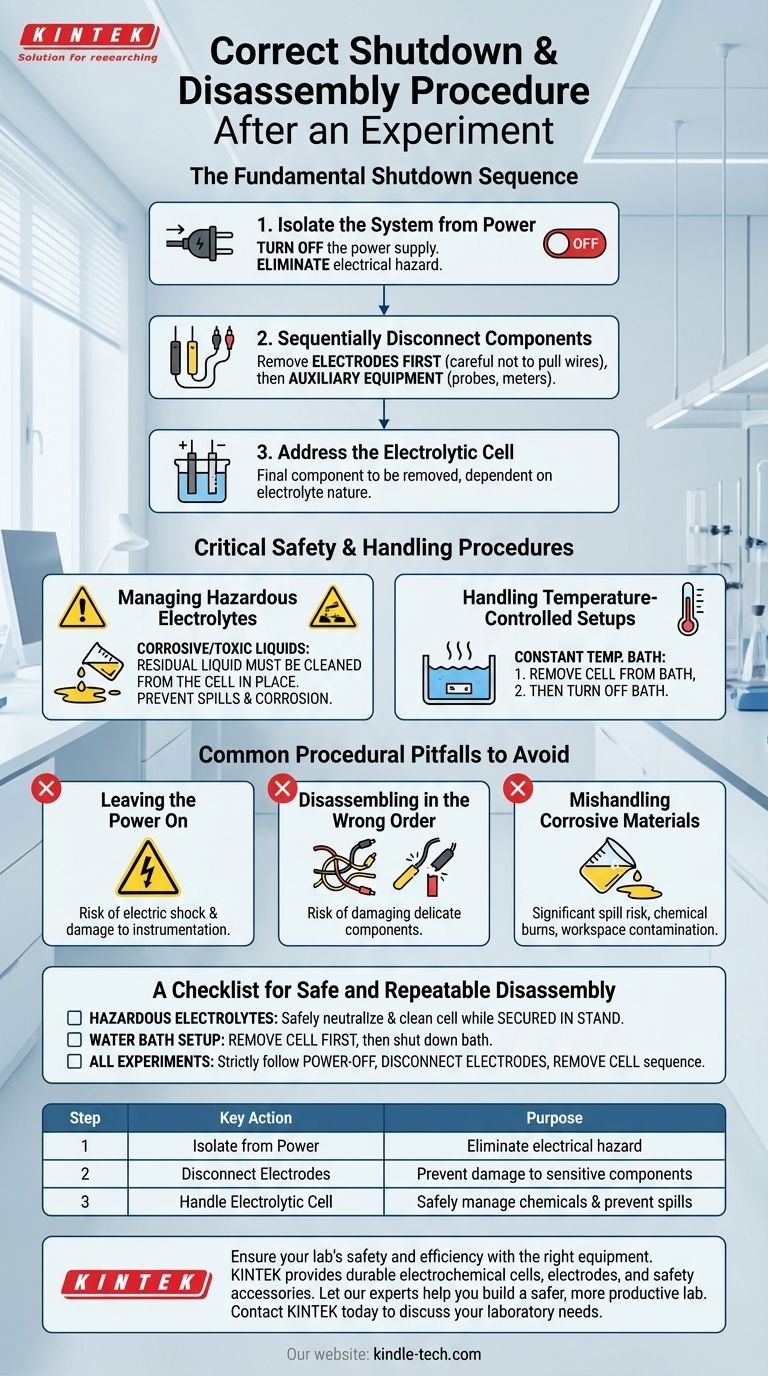

The Fundamental Shutdown Sequence

A methodical approach to disassembly ensures that every component is handled safely and preserved for future use. The core principle is to de-energize the system completely before physically interacting with it.

Step 1: Isolate the System from Power

Before touching any part of the setup, your first and most critical action is to turn off the power supply. This eliminates the primary electrical hazard and is the universal first step for any electrochemical experiment shutdown.

Step 2: Sequentially Disconnect Components

Once the system is de-energized, begin disconnecting the physical components. Remove the electrodes first, taking care not to pull on the wires, as this can damage the terminals and compromise future connections.

After the electrodes are safely stored, you can disconnect any auxiliary equipment, such as pH meters, temperature probes, or reference electrodes.

Step 3: Address the Electrolytic Cell

The final major component to be removed is the electrolytic cell. Its handling depends heavily on the nature of the electrolyte used during the experiment.

Critical Safety and Handling Procedures

Beyond the basic sequence, specific procedures are required to manage common experimental conditions like hazardous chemicals or temperature control. These steps are non-negotiable for maintaining a safe lab environment.

Managing Hazardous Electrolytes

If the electrolyte is corrosive (like strong acids or bases) or toxic, it presents a significant risk. The residual liquid must be cleaned from the cell before you attempt to disassemble the cell from its stand or support structure.

This in-place cleaning prevents accidental spills, which could damage the lab bench, corrode the stand, or cause personal injury.

Handling Temperature-Controlled Setups

For experiments using a constant temperature water bath, there is a specific order of operations. First, remove the electrolytic cell from the water bath. Only after the cell is clear should you turn off the water bath itself.

This prevents any potential accidents that could occur from handling the cell while the heating or circulation systems are still active.

Common Procedural Pitfalls to Avoid

Mistakes during shutdown can be costly, leading to damaged equipment or safety incidents. Adhering to the correct protocol helps you avoid these common errors.

Mistake 1: Leaving the Power On

Attempting to disconnect electrodes or handle the cell while the power supply is still active creates a serious risk of electric shock and can damage the instrumentation.

Mistake 2: Disassembling in the Wrong Order

Removing the cell before the electrodes can lead to tangled wires and increases the likelihood of knocking over or damaging the delicate and often expensive electrodes.

Mistake 3: Mishandling Corrosive Materials

Moving a cell that still contains a hazardous electrolyte is a significant spill risk. This can lead to chemical burns, damage to other equipment, and contamination of the workspace.

A Checklist for Safe and Repeatable Disassembly

Use this checklist to ensure your procedure aligns with best practices for safety and equipment preservation.

- If your experiment uses hazardous electrolytes: Your absolute priority is to safely neutralize and clean the cell while it is still secured in its stand.

- If your setup involves a water bath: Always remove the experimental cell from the bath before shutting down the bath's power and circulation.

- For all standard experiments: Strictly follow the power-off, disconnect electrodes, then remove the cell sequence to ensure safety and equipment longevity.

A disciplined shutdown procedure is the final step in a successful experiment and the first step in preparing for the next one.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Isolate from Power | Eliminate electrical hazard |

| 2 | Disconnect Electrodes | Prevent damage to sensitive components |

| 3 | Handle Electrolytic Cell | Safely manage chemicals and prevent spills |

Ensure your lab's safety and efficiency with the right equipment.

Proper shutdown procedures are essential, but they start with reliable, high-performance lab equipment. KINTEK specializes in providing durable electrochemical cells, electrodes, and safety accessories designed for easy handling and long-term use.

Let our experts help you build a safer, more productive lab. Contact KINTEK today to discuss your specific laboratory needs.

Visual Guide

Related Products

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

People Also Ask

- What are the necessary steps to prepare an all-quartz electrolytic cell before an experiment? Ensure Accuracy and Safety

- What precautions should be taken when handling and using an all-quartz electrolytic cell? Ensure Safe, Accurate, and Durable Performance

- Why is a quartz electrolytic cell used for acrylic acid wastewater? Ensure Chemical Stability & Data Integrity

- What are the primary applications of the all-quartz electrolytic cell? Essential for High-Purity & Optical Analysis

- What are the available volumes and dimensions for the all-quartz electrolytic cell? Find the Perfect Fit for Your Lab