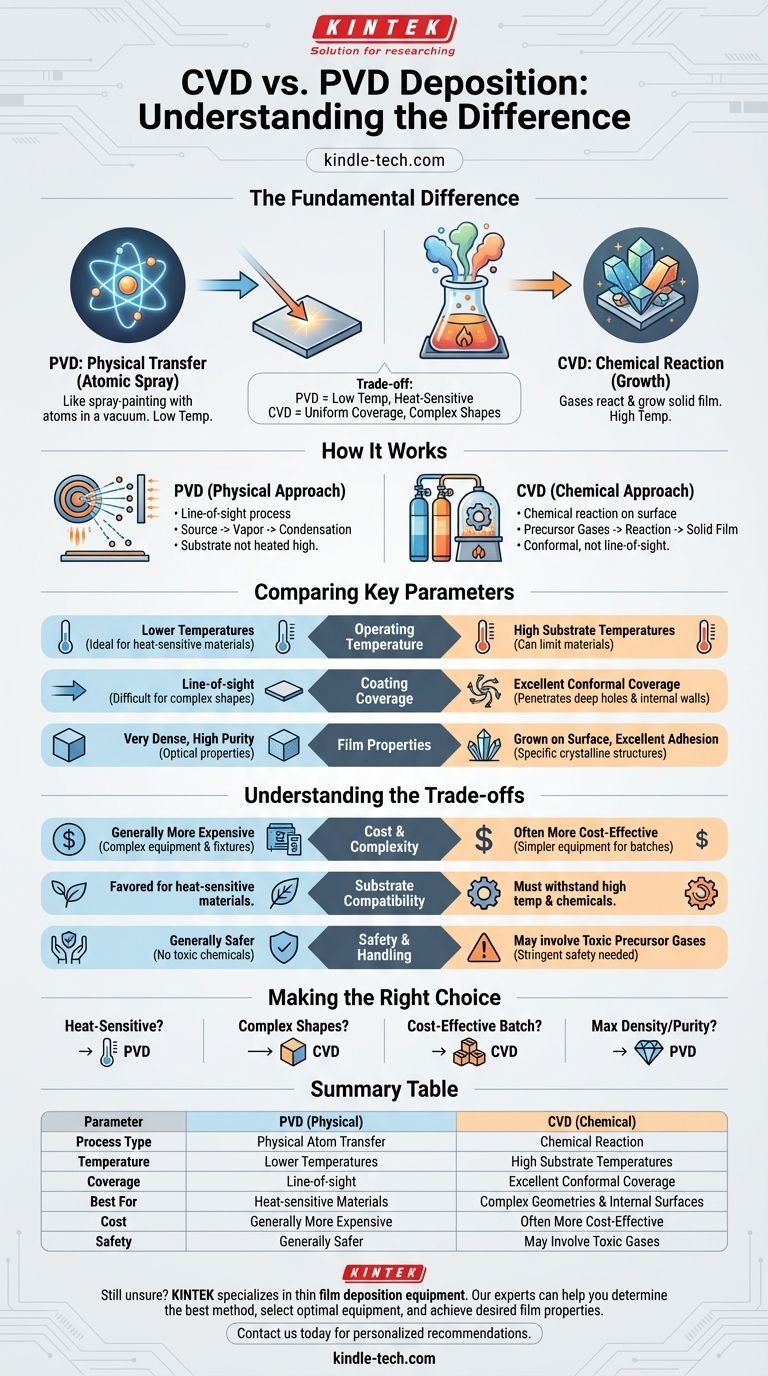

The fundamental difference between Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) lies in how they transfer material onto a surface. PVD is a physical process, like spray-painting with atoms in a vacuum. In contrast, CVD is a chemical process where gases react and "grow" a solid film directly onto a heated substrate.

The choice between PVD and CVD hinges on a critical trade-off: PVD uses physical force at lower temperatures, making it ideal for heat-sensitive components, while CVD uses chemical reactions to provide excellent, uniform coverage on complex shapes, often at a lower cost.

The Core Mechanism: Physical Transfer vs. Chemical Reaction

To select the right method, you must first understand how each one fundamentally operates. The names themselves reveal the core distinction.

How PVD Works: A Physical Approach

Physical Vapor Deposition is a line-of-sight process. It works by converting a solid or liquid source material into a vapor through physical means, such as heating or sputtering.

This vapor then travels through a vacuum chamber and condenses on the substrate, forming a thin film. Think of it as an "atomic spray painting" process where individual atoms are physically moved from the source to the target.

Because it doesn't rely on a chemical reaction at the substrate, the substrate itself does not need to be heated to high temperatures.

How CVD Works: A Chemical Approach

Chemical Vapor Deposition relies on a chemical reaction occurring directly on the surface of the part you want to coat.

Precursor gases are introduced into a reaction chamber containing the heated substrate. The heat provides the energy needed to trigger a chemical reaction, causing a solid material to form and deposit onto the substrate as a thin film.

This process is not line-of-sight. Because the precursor gases can flow around and into complex features, CVD is exceptionally good at creating uniform coatings.

Comparing Key Process Parameters

The differences in their core mechanisms lead to very different process characteristics, which directly impact their suitability for specific applications.

Operating Temperature

CVD typically requires high substrate temperatures to drive the necessary chemical reactions. This can limit the types of materials that can be coated without being damaged or altered.

PVD generally operates at much lower temperatures. This makes it the preferred method for coating substrates that are sensitive to heat, such as plastics or certain metal alloys.

Coating Coverage and Geometry

CVD excels at creating uniform, or conformal, coatings on parts with complex geometries. The reactive gases can easily penetrate deep holes and coat internal walls evenly.

PVD is a line-of-sight technique. This makes it difficult to achieve uniform coverage on intricate shapes, as surfaces not directly facing the source material will receive little to no coating.

Film Properties

PVD coatings tend to be very dense, often with less void formation compared to some CVD processes. This can be critical for applications requiring high purity or specific optical properties.

CVD films are "grown" onto the surface, which can result in excellent adhesion and specific crystalline structures depending on the process parameters.

Understanding the Trade-offs

Neither method is universally superior. The optimal choice is always dictated by the application's specific constraints and requirements.

Cost and Complexity

CVD is often more cost-effective for batch processing. The equipment can be simpler, and it provides excellent coating properties on all surfaces of a tool without complex fixtures.

PVD is generally a more expensive process. This is often due to its more complex loading and fixing requirements inside the vacuum chamber and the sophisticated equipment needed to generate the material vapor.

Substrate Compatibility

The choice is heavily influenced by the substrate material. You must consider the material's temperature sensitivity, which often favors PVD.

For CVD, you must ensure the substrate is compatible with the chemical precursors and can withstand the required deposition temperature.

Safety and Handling

PVD is considered a safer process. It does not typically involve toxic or volatile chemicals, simplifying handling and environmental controls.

CVD processes often use reactive, and sometimes toxic, precursor gases. This necessitates more stringent safety protocols and handling procedures.

Making the Right Choice for Your Application

To make a definitive decision, evaluate your project's primary goal against the core strengths of each technology.

- If your primary focus is coating heat-sensitive materials: PVD is the clear choice due to its significantly lower operating temperatures.

- If your primary focus is coating complex shapes or internal surfaces uniformly: CVD's ability to conformally coat intricate geometries is unmatched.

- If your primary focus is cost-effective batch coating of durable tools: CVD often provides the most economical solution with excellent coverage.

- If your primary focus is achieving maximum film density or purity on a simple geometry: PVD can provide superior film quality for these applications.

Understanding this core distinction between a physical transfer and a chemical reaction empowers you to select the precise tool for your engineering challenge.

Summary Table:

| Parameter | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical atom transfer | Chemical reaction on substrate |

| Temperature | Lower temperatures | High substrate temperatures |

| Coverage | Line-of-sight | Excellent conformal coverage |

| Best For | Heat-sensitive materials | Complex geometries & internal surfaces |

| Cost | Generally more expensive | Often more cost-effective for batches |

| Safety | Generally safer | May involve toxic precursor gases |

Still unsure which deposition method is right for your application?

KINTEK specializes in lab equipment and consumables for thin film deposition processes. Our experts can help you:

- Determine whether PVD or CVD better suits your substrate and coating requirements

- Select the optimal equipment for your specific laboratory needs

- Ensure you achieve the desired film properties and performance

Contact us today to discuss your project requirements and get personalized recommendations for your deposition challenges. Get in touch with our experts now!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- Are all lab grown diamonds CVD? Understanding the Two Main Methods

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What is the floating catalyst method? A Guide to High-Yield CNT Production