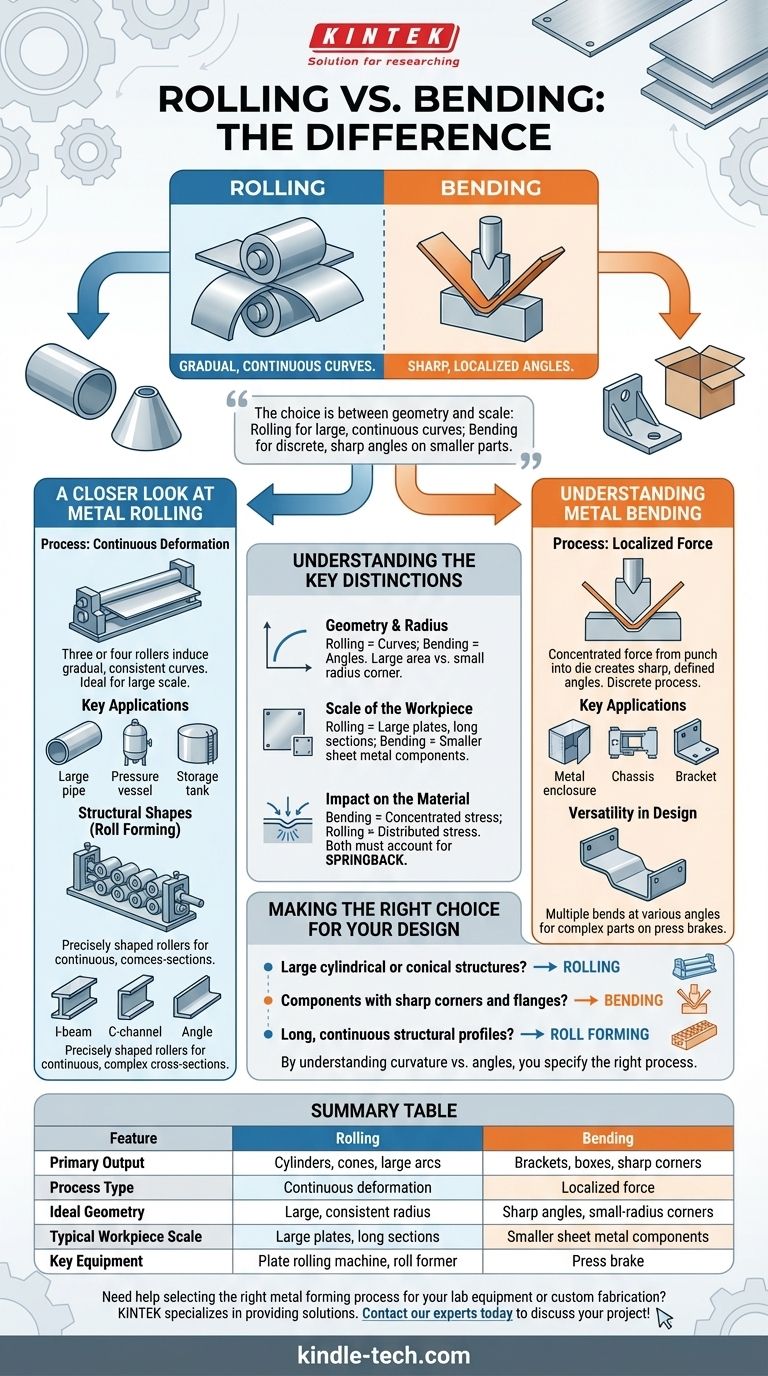

The fundamental difference between rolling and bending lies in how a material is shaped: rolling creates gradual, large-radius curves through continuous pressure, while bending creates sharp, localized angles or small-radius curves by applying force at a specific point. Rolling is used to make cylinders, cones, and large arcs, whereas bending is used to create brackets, boxes, and sharp corners.

The choice between rolling and bending is a choice between geometry and scale. Select rolling for continuous, large-radius curvatures on large workpieces, and select bending for creating discrete, sharp angles on smaller, more complex parts.

A Closer Look at Metal Rolling

Metal rolling is a forming process that uses a set of rollers to reduce the thickness of, or impart a desired shape to, a piece of metal. It's a continuous process ideal for large-scale production and large parts.

The Rolling Process: Continuous Deformation

In processes like plate rolling, a sheet or plate of metal is fed through three or four rollers. By adjusting the distance and position of these rollers, the machine induces a gradual, consistent curve along the entire length or width of the workpiece. This progressive pressure ensures a smooth, uniform radius.

Key Applications for Rolling

This method is the go-to choice for manufacturing parts with a large, consistent radius. Common examples include large-diameter pipes, pressure vessels, storage tanks, and the conical sections of hoppers.

Structural Shapes

A specialized form called roll forming uses a series of precisely shaped rollers to progressively bend a continuous strip of metal into complex cross-sections, such as I-beams, C-channels, and angle iron.

Understanding Metal Bending

Bending is a fabrication process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials. It is most commonly performed on a machine tool called a press brake.

The Bending Process: Localized Force

A press brake uses a punch and a die to apply concentrated force to a specific line on a sheet of metal. The punch presses the sheet into the die, forcing it to bend at a sharp, defined angle. The process is discrete, creating one bend at a time.

Key Applications for Bending

Bending is essential for creating components that require sharp corners and flanges. Think of metal enclosures for electronics, chassis for equipment, small brackets, and sheet metal boxes.

Versatility in Design

Because each bend is a separate operation, press brakes offer immense versatility for creating complex parts with multiple bends at various angles and in different directions on a single workpiece.

Understanding the Key Distinctions

While both processes shape metal, their core principles, applications, and equipment are fundamentally different. The decision of which to use is rarely ambiguous.

Geometry and Radius

This is the most critical distinction. Rolling is for curves; bending is for angles. Rolling excels at producing a true radius over a large area. Bending excels at creating a small-radius corner along a straight line.

Scale of the Workpiece

Rolling machines are built to handle large plates and long sections of metal, often many feet in length or width. Press brakes are typically used for smaller, more manageable sheet metal components, although very large brakes exist for specialized applications like forming ship hulls.

Impact on the Material

Bending concentrates stress along a very narrow line, which can affect the material's properties at the corner. Rolling distributes the forming stress more evenly across the entire curved surface of the part. Both processes must account for springback, where the material tries to return to its original shape after the force is removed.

Making the Right Choice for Your Design

Selecting the correct process is critical for achieving your design intent efficiently and cost-effectively. Your part's geometry will almost always provide a clear answer.

- If your primary focus is creating large cylindrical or conical structures: Rolling is the only practical and efficient method for this task.

- If your primary focus is fabricating components with sharp corners and flanges: Bending on a press brake is the correct and necessary process.

- If your primary focus is forming long, continuous structural profiles: Roll forming is the ideal high-volume production method.

By understanding the distinction between continuous curvature and localized angles, you can specify the right manufacturing process for a more robust and economical design.

Summary Table:

| Feature | Rolling | Bending |

|---|---|---|

| Primary Output | Cylinders, cones, large arcs | Brackets, boxes, sharp corners |

| Process Type | Continuous deformation | Localized force |

| Ideal Geometry | Large, consistent radius | Sharp angles, small-radius corners |

| Typical Workpiece Scale | Large plates, long sections | Smaller sheet metal components |

| Key Equipment | Plate rolling machine, roll former | Press brake |

Need help selecting the right metal forming process for your lab equipment or custom fabrication project? At KINTEK, we specialize in providing solutions for laboratory needs, from custom metal enclosures to specialized components. Our expertise ensures you get the most efficient and cost-effective manufacturing method for your design. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Double Plate Heating Press Mold for Lab

- Small Lab Rubber Calendering Machine

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- Automatic Laboratory Heat Press Machine

People Also Ask

- What happens if hydraulic pressure is too low? Avoid System Failure and Costly Damage

- Why is a laboratory hydraulic press required for boron carbide ceramic green bodies? Mastering Precise Pressure Loads

- What role does a laboratory hydraulic press play in platinum recovery research? Enhancing Sample Precision

- What are the disadvantages of a hydraulic press? Low Speed, High Maintenance & Energy Costs

- Why is a laboratory hydraulic press necessary for Al-Fe-Ni alloy powder? Achieve Optimal Preform Density

- What is the purpose of using a laboratory hydraulic press? Achieve Precision in Diamond-Aluminum Powder Processing

- What are the different types of mechanical presses? Choose the Right Press for Your Application

- What are the 2 steps you must follow when operating a hydraulic press? Master Safe & Precise Operation