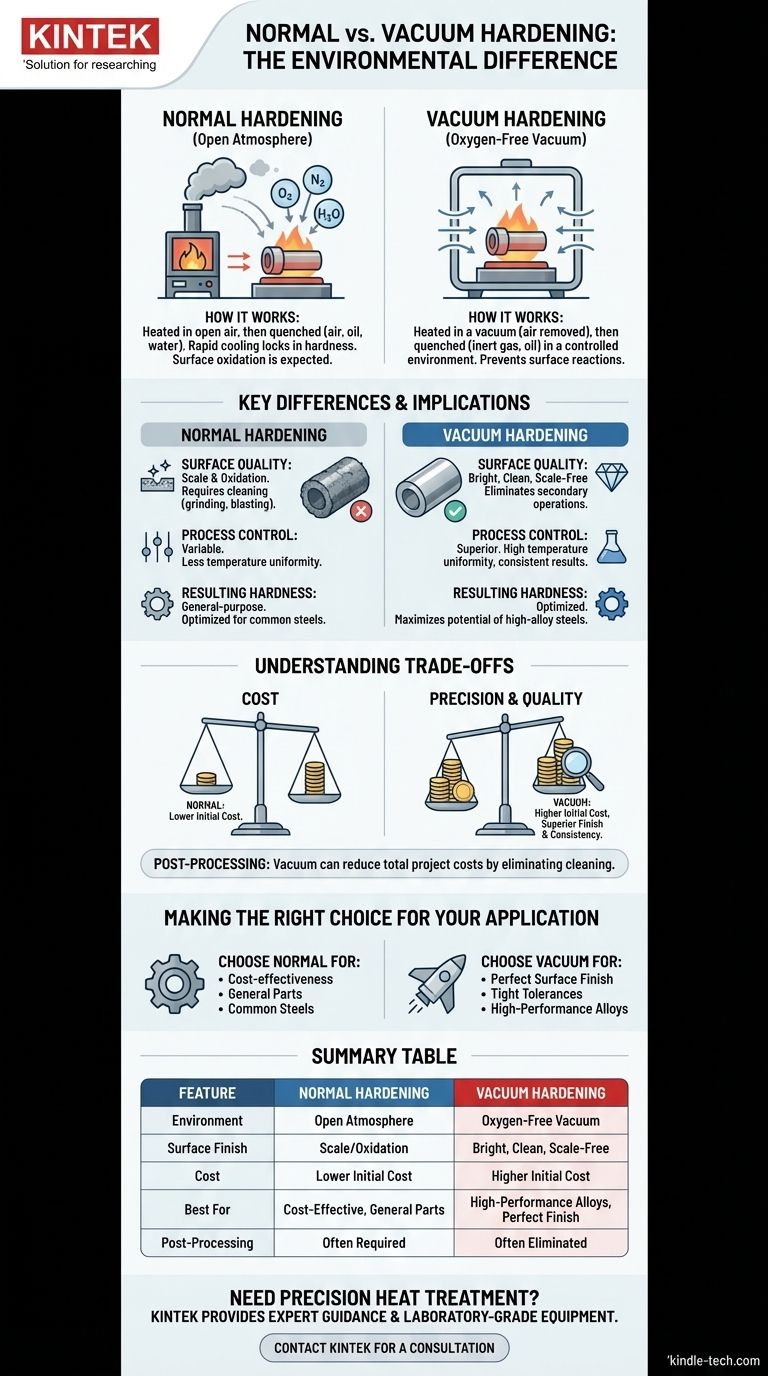

At its core, the difference is the environment. Normal hardening heats a metal part in the open atmosphere, while vacuum hardening performs the heating process inside a vacuum chamber where the air has been removed. This fundamental change in environment prevents oxygen from reacting with the metal's surface during the critical heating phase.

The central trade-off is between cost and quality. Normal hardening is a cost-effective, robust process for general-purpose strengthening, while vacuum hardening is a precision method that delivers superior surface finish and consistency for more demanding applications.

How Each Process Fundamentally Works

To understand the differences in outcome, you must first understand the differences in process. Both methods aim to alter a metal's microstructure to increase hardness and durability, but they take different paths to get there.

The Principle of Normal Hardening

Normal hardening is the most common form of heat treatment. The metal is heated in a furnace to its critical temperature, held for a specific time, and then rapidly cooled—or quenched—in a medium like air, oil, or water.

This rapid cooling locks in a hardened microstructure, significantly improving the material's toughness and wear resistance. Because it occurs in the presence of atmospheric gases, some surface oxidation or scaling is an expected outcome.

The Principle of Vacuum Hardening

Vacuum hardening is a more advanced process that begins by placing the part inside a sealed furnace. The system then removes the air to create a vacuum, establishing an oxygen-free environment.

Only after the vacuum is established is the part heated to its critical temperature. This completely prevents surface reactions like oxidation and decarburization. Quenching is typically done using high-pressure inert gas or oil within the controlled environment.

Key Differences and Their Implications

The choice to use a vacuum fundamentally changes the results, creating clear distinctions between the two methods.

Surface Quality and Finish

This is the most significant advantage of vacuum hardening. By eliminating oxygen, the process produces parts with a bright, clean, metallic surface that is free from scale.

This often eliminates the need for secondary operations like grinding, sand-blasting, or acid cleaning, which are frequently required after normal hardening to restore the desired surface finish.

Process Control and Consistency

Vacuum furnaces provide a highly controlled environment, offering superior temperature uniformity across the entire part.

This level of precision ensures more consistent and repeatable results from one batch to the next, which is critical for components with tight metallurgical or dimensional tolerances.

Resulting Hardness and Performance

While both methods increase hardness, the precision of vacuum hardening allows for optimizing the heat treatment cycle for specific alloys.

This control ensures the material can achieve its maximum potential hardness and performance characteristics without the negative surface effects that can occur during atmospheric heating.

Understanding the Trade-offs

Choosing the right process requires balancing project requirements with practical constraints.

Cost vs. Precision

There is no ambiguity here: vacuum hardening is more expensive. The equipment is more complex, and cycle times can be longer.

This higher upfront cost is justified when the application demands superior surface quality, dimensional stability, and metallurgical purity. Normal hardening remains the go-to for its cost-effectiveness in less critical applications.

Post-Processing Requirements

The initial cost is not the whole story. While vacuum hardening is more expensive, it can reduce total project costs by eliminating the need for post-treatment machining or cleaning.

Normal hardening is cheaper initially, but you must account for the labor and time required to remove the resulting surface scale and bring the part back to its specified dimensions.

Material Suitability

Vacuum hardening is particularly well-suited for high-alloy tool steels, stainless steels, and other advanced materials that are highly sensitive to surface oxidation or decarburization. Normal hardening is a robust solution for a wide range of common carbon and alloy steels.

Making the Right Choice for Your Application

Your final decision should be driven by the specific demands of your component and its end-use.

- If your primary focus is cost-effectiveness for general parts: Normal hardening provides the necessary strength and durability for a vast range of applications at a lower cost.

- If your primary focus is a perfect surface finish or tight dimensional tolerances: Vacuum hardening is the superior choice, as it eliminates scale and reduces the risk of part distortion.

- If your primary focus is consistent results for high-performance alloys: Vacuum hardening offers the process control required to get the most out of sensitive and high-value materials.

Ultimately, choosing the right hardening process is about aligning the method's capabilities with your component's specific engineering requirements.

Summary Table:

| Feature | Normal Hardening | Vacuum Hardening |

|---|---|---|

| Environment | Open Atmosphere | Oxygen-Free Vacuum |

| Surface Finish | Scale/Oxidation (Requires Cleaning) | Bright, Clean, Scale-Free |

| Cost | Lower Initial Cost | Higher Initial Cost |

| Best For | Cost-Effective, General-Purpose Parts | High-Performance Alloys, Perfect Finish |

| Post-Processing | Often Required (Grinding, Blasting) | Often Eliminated |

Need Precision Heat Treatment for Your Critical Components?

Choosing between vacuum and normal hardening is crucial for achieving the right balance of performance, surface quality, and cost for your metal parts. The experts at KINTEK are here to help.

We provide:

- Expert Guidance: Our team will analyze your specific material and application requirements to recommend the optimal hardening process.

- Superior Results: Whether your project demands the cost-effectiveness of normal hardening or the pristine, scale-free finish of vacuum hardening, we deliver consistent, high-quality results.

- Laboratory-Grade Equipment: KINTEK specializes in lab equipment and consumables, serving precise laboratory needs with reliable thermal processing solutions.

Let's discuss your project requirements and ensure your components meet the highest standards.

Contact KINTEK today for a consultation

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a high-temperature annealing furnace facilitate the homogenization of high-entropy alloys and stainless steels?

- How does temperature affect vacuum pressure? Master the Key to System Control

- What role do high-temperature furnaces play in RAFM steel pretreatment? Achieve Precise Microstructural Stability

- Why is graphite generally used as a refractory material for lining electric furnaces? Unmatched Performance & Efficiency

- What is the primary function of a vacuum arc furnace in the preparation of Fe-Mn-Cr shape memory alloys?

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What do sintering temperatures range from? Unlock the Key to Perfect Material Densification

- Is heat treatment a strengthening mechanism? Unlock Tailored Material Strength