In short, the single greatest disadvantage of an induction furnace is its lack of refining capacity. This means it cannot effectively remove impurities from the raw materials it melts. The charge materials must already be clean and of a known composition, as the furnace essentially only remelts the metal, preserving both its quality and its flaws.

While highly efficient and precise, an induction furnace is fundamentally a remelting device, not a refining tool. Its primary limitation is its inability to process dirty, oxidized, or compositionally unknown scrap metal, which can significantly increase raw material costs.

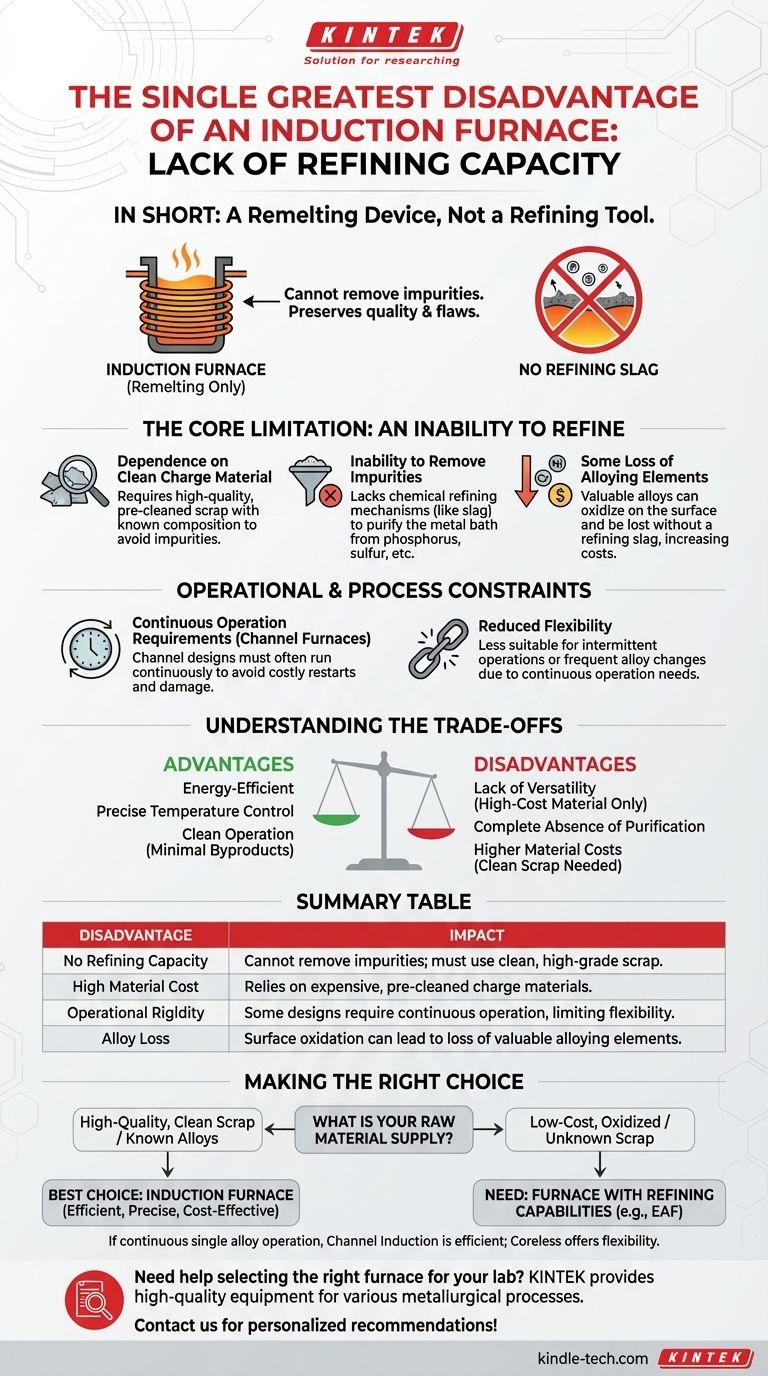

The Core Limitation: An Inability to Refine

The central drawback of induction furnace technology stems from its clean, contained heating method. Unlike furnaces that use chemical reactions or slag, an induction furnace lacks the mechanisms to purify the metal bath.

Dependence on Clean Charge Material

Because there is no refining process, the quality of the finished product is entirely dependent on the quality of the material you put in.

Charge materials must be free of excessive rust and other oxides. This often means operators must use more expensive, higher-grade scrap or pre-cleaned materials.

Inability to Remove Impurities

Traditional furnaces, like the Electric Arc Furnace (EAF), use a slag layer to chemically bind with and remove impurities such as phosphorus and sulfur from the molten metal.

Induction furnaces do not use a slag chemistry for purification, making them unsuitable for primary steelmaking or melting low-grade, contaminated scrap.

Some Loss of Alloying Elements

While the induction process itself is cleaner than combustion, some oxidation of valuable alloying elements can still occur on the surface of the melt.

Without a refining slag to recover these oxides, the elements are lost and must be re-added to the melt to meet the required chemical specification, adding cost and complexity.

Operational and Process Constraints

Beyond its metallurgical limitations, the design of certain induction furnaces imposes strict operational requirements.

Continuous Operation Requirements

Certain designs, particularly channel induction furnaces, operate most efficiently when run continuously.

The narrow metal loop or channel must remain full of molten metal to function. Allowing it to cool and solidify can cause significant damage and require costly, time-consuming maintenance to restart.

Reduced Flexibility

This need for continuous operation makes channel furnaces less suitable for facilities that run on single shifts or require frequent shutdowns.

They are best suited for high-throughput, high-production operations with very few changes in the alloy being produced.

Understanding the Trade-offs

The disadvantages of an induction furnace are directly linked to its advantages. The choice to use one is a matter of weighing these critical trade-offs.

Efficiency vs. Versatility

Induction furnaces are exceptionally energy-efficient because the heat is generated directly within the metal itself.

However, this efficiency is paid for with a lack of versatility. You cannot take advantage of low-cost, low-grade scrap metal as a raw material source.

Precision vs. Purification

The technology offers unparalleled precision in temperature control, preventing the overheating and loss of valuable alloys.

The trade-off is the complete absence of purification. The furnace precisely preserves the chemistry of the charge material, for better or for worse.

Clean Operation vs. Material Cost

The process is celebrated for its clean operation, with no combustion byproducts, minimal dust, and a safer working environment.

This environmental benefit is predicated on higher material costs, as the furnace offloads the responsibility of "cleaning" to the scrap supplier or a pre-processing step.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on your raw material supply and desired final product.

- If your primary focus is melting high-quality, clean scrap or known alloys: The induction furnace is likely the most efficient, precise, and cost-effective tool for the job.

- If your primary focus is processing low-cost, oxidized, or compositionally unknown scrap: You require a furnace with active refining capabilities, which an induction furnace cannot provide.

- If your operation runs continuously on a single alloy: A channel induction furnace offers excellent efficiency, but a coreless design provides more flexibility for intermittent work.

Understanding this core distinction between remelting and refining is the key to selecting the right technology for your metallurgical process.

Summary Table:

| Disadvantage | Impact |

|---|---|

| No Refining Capacity | Cannot remove impurities; must use clean, high-grade scrap. |

| High Material Cost | Relies on expensive, pre-cleaned charge materials. |

| Operational Rigidity | Some designs require continuous operation, limiting flexibility. |

| Alloy Loss | Surface oxidation can lead to loss of valuable alloying elements. |

Need help selecting the right furnace for your lab's specific melting and refining needs? KINTEK specializes in providing high-quality lab equipment, including furnaces tailored for various metallurgical processes. Whether you're working with high-purity alloys or require refining capabilities, our experts can help you choose the perfect solution for efficiency and cost-effectiveness. Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation