In sputtering, process pressure is the primary lever for controlling film quality. It directly governs the energy of the sputtered particles as they travel from the target to your substrate. This energy, in turn, dictates critical film properties such as density, adhesion, smoothness, and internal stress.

The core principle to understand is that sputtering pressure controls a critical trade-off. Lowering pressure increases the energy of sputtered atoms—which generally improves film density and adhesion—but dropping it too low can destabilize the plasma and introduce defects.

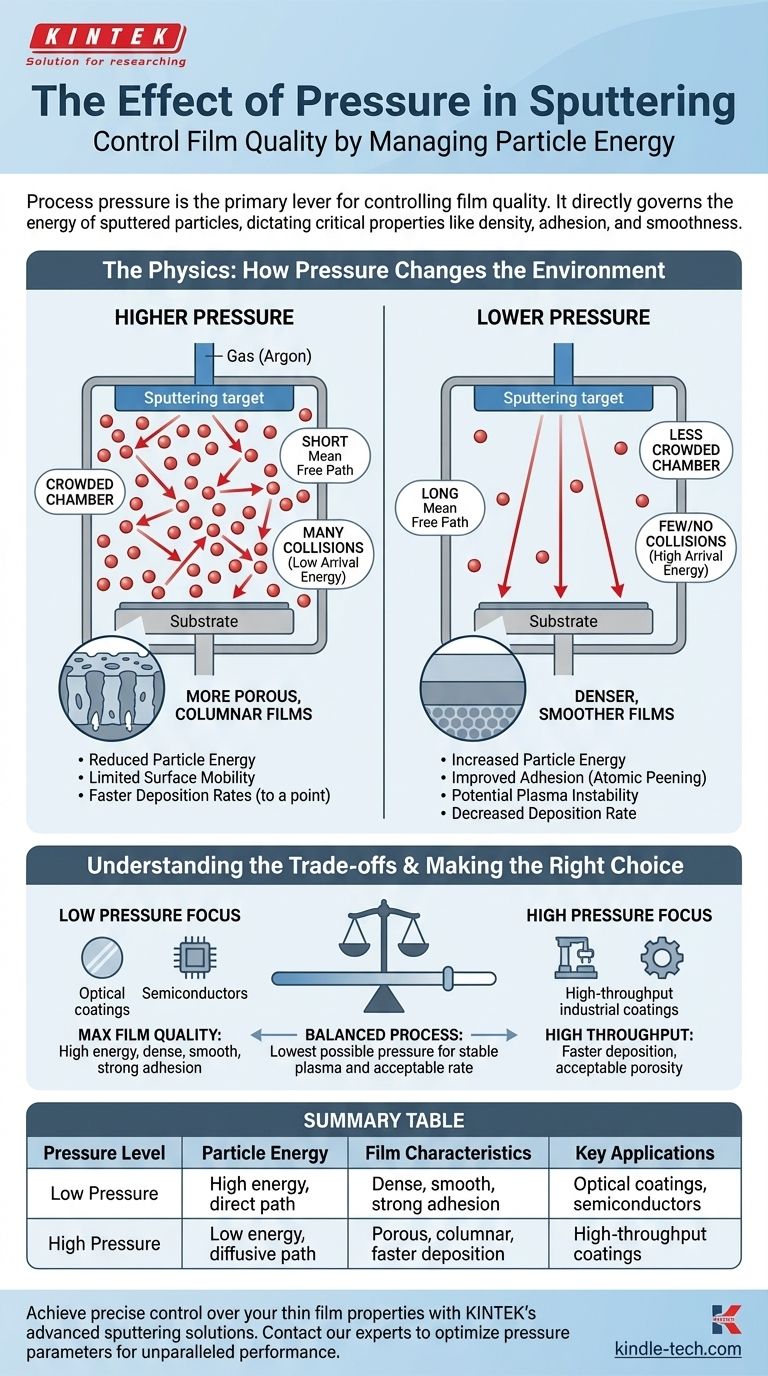

The Physics: How Pressure Changes the Sputtering Environment

To understand the effects, we must first look at the environment inside the chamber. The key is understanding how many gas atoms (typically Argon) exist between the sputtering target and the substrate.

Defining Mean Free Path

The mean free path is the average distance a particle can travel before colliding with another particle.

At high pressure, the chamber is crowded with gas atoms. The mean free path is very short, meaning a sputtered atom will collide many times on its way to the substrate.

At low pressure, the chamber is much less crowded. The mean free path is long, and a sputtered atom may experience very few or even no collisions before it arrives.

Energy is Everything

Each collision between a sputtered atom and a gas atom causes the sputtered atom to lose kinetic energy and change its direction.

Therefore, the process pressure is your control knob for the final arrival energy of the atoms building your thin film.

The Impact of Lower Sputtering Pressure

Lowering the working gas pressure is often done to create higher-quality films for demanding applications.

Increased Particle Energy

With a longer mean free path, sputtered atoms retain most of their initial high energy. They arrive at the substrate like energetic projectiles, traveling in a more direct, line-of-sight path.

Denser and Smoother Films

These high-energy atoms have enough mobility on the substrate surface to move around, find the most stable lattice sites, and fill in microscopic voids. This process, known as atomic peening, results in a denser, less porous, and smoother film structure.

Improved Adhesion

The high kinetic energy helps the arriving atoms implant slightly into the substrate surface, creating a stronger interfacial bond and significantly improving film adhesion.

Understanding the Trade-offs: The Dangers of Low Pressure

While low pressure offers significant benefits, pushing it too far creates a different set of problems. There is always an optimal window for any given process.

Plasma Instability

Sputtering requires a stable plasma (glow discharge) to function. If the pressure is too low, there are not enough gas atoms to reliably sustain the plasma, causing it to become unstable or extinguish entirely.

Formation of Defects

An unstable or non-ideal deposition mechanism at very low pressures can lead to poor film growth. This can manifest as a decrease in film density and the formation of crystalline defects, such as "needle defects."

Decreased Deposition Rate

While the quality may be higher, lower pressure generally means fewer argon ions are available to bombard the target, which can reduce the overall sputtering rate and increase process time.

The Impact of Higher Sputtering Pressure

Conversely, operating at a higher pressure creates a very different film.

Reduced Particle Energy

Due to the short mean free path, sputtered atoms undergo numerous collisions. They arrive at the substrate with very little energy, diffusing through the gas rather than traveling directly.

More Porous, Columnar Films

Low-energy atoms have limited surface mobility. They tend to "stick where they land," leading to a more porous film with a distinct columnar grain structure and lower density.

Higher Deposition Rates (to a point)

A higher pressure can increase the density of the plasma, leading to a higher flux of ions bombarding the target and, consequently, a faster deposition rate. This is often a necessary trade-off for high-throughput applications.

Making the Right Choice for Your Process

Selecting the correct pressure is not about finding a single "best" value, but about matching the parameter to your specific goal.

- If your primary focus is maximum film quality (e.g., for optical coatings or semiconductors): Start with a lower process pressure to maximize particle energy, creating dense, smooth, and well-adhered films.

- If your primary focus is high throughput and speed: A moderately higher pressure can increase the deposition rate, but you must accept a likely reduction in film density and performance.

- If your primary focus is a balanced, stable process: The goal is to find the lowest possible pressure that maintains a stable plasma and provides an acceptable deposition rate for your needs.

Ultimately, mastering pressure is about precisely controlling particle energy to achieve your desired film characteristics.

Summary Table:

| Pressure Level | Particle Energy | Film Characteristics | Key Applications |

|---|---|---|---|

| Low Pressure | High energy, direct path | Dense, smooth, strong adhesion | Optical coatings, semiconductors |

| High Pressure | Low energy, diffusive path | Porous, columnar, faster deposition | High-throughput coatings |

Achieve precise control over your thin film properties with KINTEK's advanced sputtering solutions. Our lab equipment and consumables are designed to help you optimize pressure parameters for unparalleled film density, adhesion, and performance. Contact our experts today to discuss how we can support your laboratory's specific deposition needs and enhance your research outcomes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials