The effective size of a sieve is a specific measurement derived from a soil or aggregate sample, not a property of the sieve itself. Known as D10, it represents the particle diameter (in millimeters) where 10% of the sample's particles, by weight, are smaller than this size, and 90% are larger. This value is a critical indicator of a granular material's hydraulic properties, particularly its permeability.

The term "effective size" is shorthand for the D10 value of a material being tested. It is the single most important property for estimating the permeability and drainage characteristics of granular soils like sand and gravel.

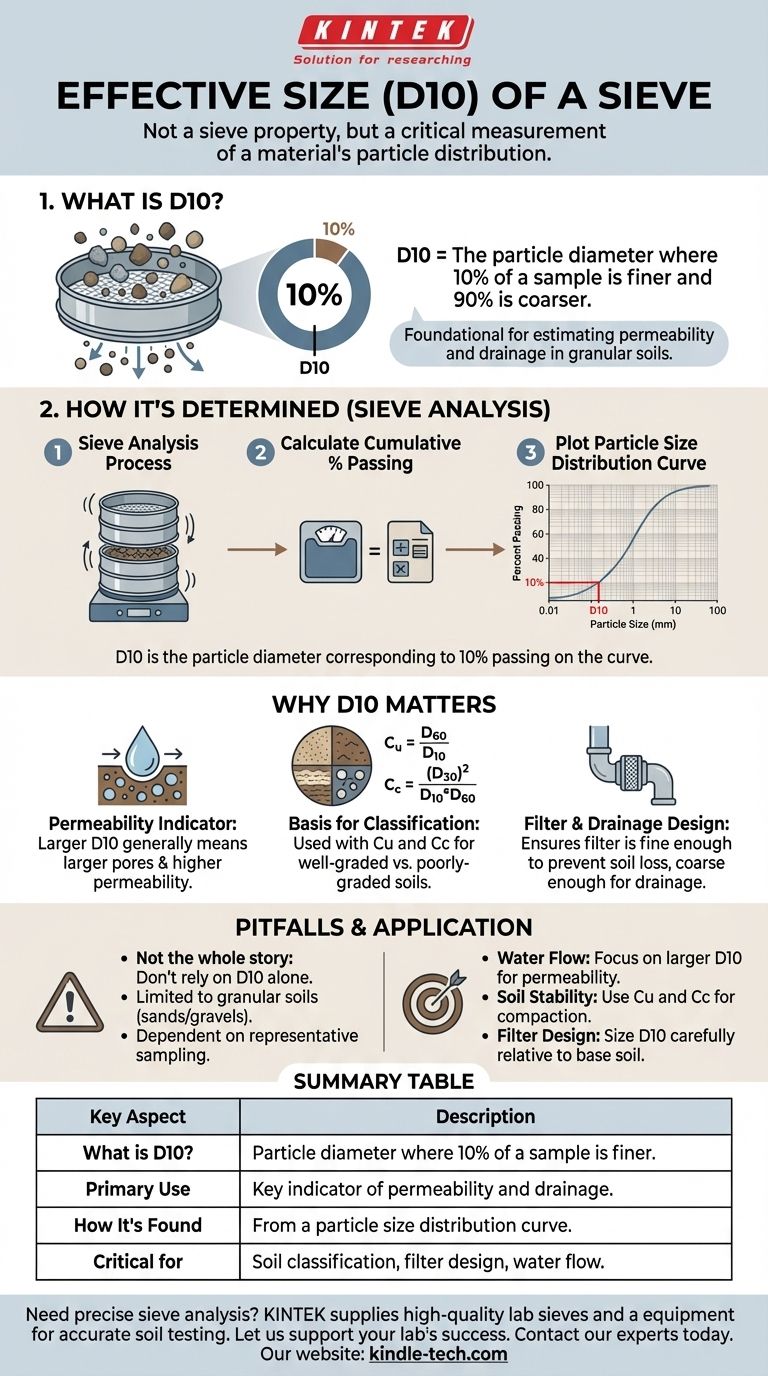

How the Effective Size (D10) is Determined

The effective size is not a direct measurement but an interpretation derived from a standard laboratory procedure called a sieve analysis.

The Sieve Analysis Process

A representative, dried sample of the material is weighed and passed through a stack of sieves with progressively smaller mesh openings. The stack is mechanically shaken, sorting the particles by size.

Calculating Cumulative Percent Passing

After shaking, the material retained on each sieve is weighed. From this data, you calculate the cumulative percentage of the total sample weight that has passed through each sieve size.

Plotting the Particle Size Distribution Curve

The results are plotted on a semi-logarithmic graph. The vertical axis shows the "Percent Passing" (from 0% to 100%), and the horizontal axis shows the particle size (sieve opening) in millimeters on a log scale.

Identifying D10 on the Curve

To find the effective size, you locate the 10% mark on the "Percent Passing" axis. You then move horizontally until you intersect the plotted curve and drop down vertically to the particle size axis. The corresponding diameter in millimeters is the D10, or effective size.

Why D10 is So Important in Practice

The D10 value, despite being a simple metric, is foundational for predicting the behavior of granular materials in civil engineering and geology.

A Key Indicator of Permeability

The size of the finer 10% of particles largely controls the size of the pores through which water must flow. A larger D10 value generally corresponds to larger pores and, therefore, higher permeability (the ease with which water can move through the material).

The Basis for Soil Classification

D10 is a required input for calculating two other essential soil grading parameters:

- Uniformity Coefficient (Cu = D60 / D10): This ratio indicates the range of particle sizes in the sample. A low Cu means the particles are all very similar in size.

- Coefficient of Curvature (Cc = (D30)² / (D10 * D60)): This value describes the smoothness and shape of the gradation curve.

Together, Cu and Cc are used in systems like the Unified Soil Classification System (USCS) to classify a soil as well-graded (a wide range of particle sizes) or poorly-graded (a narrow range of sizes).

Critical for Filter and Drainage Design

In designing drainage systems or filters for dams, the D10 of the filter material is carefully selected based on the properties of the soil it is meant to protect. This ensures the filter is fine enough to prevent soil particles from washing through (preventing clogging) but coarse enough to allow water to drain freely.

Common Pitfalls and Misinterpretations

While powerful, the D10 value must be used with a clear understanding of its context and limitations.

D10 Is Not the Whole Story

Relying on D10 alone can be misleading. A soil's overall behavior depends on its complete particle size distribution, which is why the Uniformity Coefficient (Cu) and Coefficient of Curvature (Cc) are always calculated alongside it.

Limited to Granular Soils

The concept of effective size is most meaningful for cohesionless, granular soils like sands and gravels. For cohesive soils like clays and silts, properties are dominated by particle shape and electrochemical forces, not just size.

Dependent on Representative Sampling

The entire analysis is only as good as the sample it is based on. A sample that is not representative of the in-situ soil will produce a D10 value that is technically correct for the sample but useless for predicting the behavior of the larger soil deposit.

Applying This to Your Goal

Your interpretation of the D10 value should be driven by your specific engineering objective.

- If your primary focus is water flow and permeability: A larger D10 value indicates a more permeable material, allowing water to pass through more easily.

- If your primary focus is soil stability and compaction: You must look beyond D10 to the Uniformity (Cu) and Curvature (Cc) coefficients to determine if the soil is well-graded and can be compacted to a dense, stable state.

- If your primary focus is designing a protective filter: The D10 of your filter material must be carefully sized relative to the base soil to ensure proper drainage without clogging.

Ultimately, the effective size is the foundational data point that unlocks a deeper understanding of a soil's mechanical and hydraulic behavior.

Summary Table:

| Key Aspect | Description |

|---|---|

| What is D10? | The particle diameter where 10% of a sample is finer and 90% is coarser. |

| Primary Use | A key indicator of a granular material's permeability and drainage characteristics. |

| How It's Found | Determined from a particle size distribution curve plotted after a sieve analysis. |

| Critical for | Soil classification, filter design, and predicting water flow through soils like sand and gravel. |

Need precise sieve analysis for your project?

Accurate particle size distribution data is the foundation of reliable geotechnical engineering. KINTEK specializes in supplying high-quality lab sieves, shakers, and equipment for soil testing. Our products help ensure your D10 measurements and gradation analyses are accurate and repeatable.

Let us support your lab's success. Contact our experts today to find the right sieves and equipment for your specific soil testing needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability