At its core, a quartz tube is a container or component made from high-purity fused quartz, designed to function in extreme environments where standard glass would fail. It is used extensively in scientific research and industrial processes that involve very high temperatures, require high chemical purity, or need transparency to ultraviolet light.

The essential function of a quartz tube is to provide a stable, inert, and transparent vessel for processes that are too demanding for conventional materials. Its value comes from a unique combination of thermal stability, chemical purity, and optical properties.

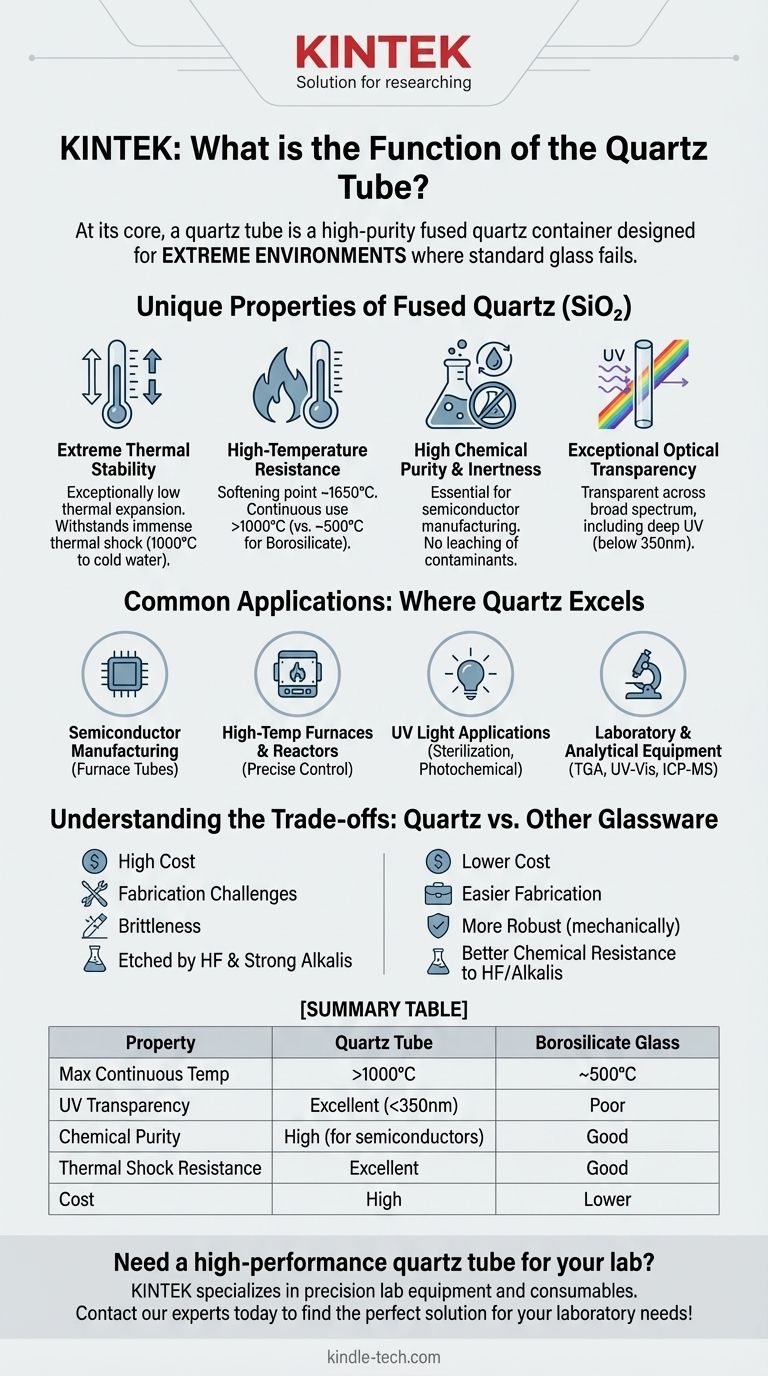

The Unique Properties of Fused Quartz

The decision to use a quartz tube instead of a more common material like borosilicate glass (Pyrex) is driven by the remarkable properties of fused quartz, which is essentially pure silicon dioxide (SiO₂).

Extreme Thermal Stability

Fused quartz has an exceptionally low coefficient of thermal expansion. This means it expands and contracts very little when its temperature changes.

As a result, it can withstand immense thermal shock. You can heat a quartz tube to over 1000°C and plunge it into cold water without it cracking, a feat that would instantly shatter normal glass.

High-Temperature Resistance

Quartz maintains its structural integrity at extremely high temperatures.

Its softening point is around 1650°C (3000°F), allowing it to be used continuously in applications well over 1000°C. In contrast, borosilicate glass begins to soften around 820°C (1500°F).

High Chemical Purity and Inertness

Quartz tubes are valued for their exceptional purity. Because they are made from nearly pure SiO₂, they do not leach metallic ions or other contaminants into the materials they contain.

This makes them essential for processes like semiconductor manufacturing, where even parts-per-billion contamination can ruin a product, and in trace element analysis where sample purity is paramount.

Exceptional Optical Transparency

Unlike borosilicate and other standard glasses, quartz is transparent across a very broad spectrum of light, including deep into the ultraviolet (UV) range.

Regular glass blocks most UV light below 350 nanometers. Quartz, however, allows UV light to pass through, making it the only viable choice for applications like UV sterilization lamps and photochemical reactors.

Common Applications: Where Quartz Tubes Excel

The properties of quartz dictate its use in a range of high-performance applications.

Semiconductor Manufacturing

Quartz furnace tubes are fundamental to creating silicon wafers. They provide the ultra-pure, high-temperature environment needed to diffuse chemicals into silicon or grow oxide layers on the wafer surface.

High-Temperature Furnaces and Reactors

In materials science and chemistry, quartz tubes are used as chambers for high-temperature synthesis, annealing, or combustion analysis. Their thermal stability allows for precise temperature control without material failure.

UV Light Applications

The UV transparency of quartz is critical for devices that use ultraviolet light. This includes water purification systems, air sterilizers, EPROM erasers, and laboratory equipment for photochemical reactions.

Laboratory and Analytical Equipment

Quartz is often used for sample holders in thermogravimetric analysis (TGA), as cuvettes for UV-Visible spectroscopy, and as torch components in ICP-MS instruments, all of which involve high heat, purity, or UV light.

Understanding the Trade-offs: Quartz vs. Other Glassware

While superior in many ways, quartz is not always the best choice. Understanding its limitations is key to making an informed decision.

The Cost Factor

The primary drawback of quartz is its cost. It is significantly more expensive than borosilicate glass due to the energy-intensive process required to melt and purify sand into fused quartz.

Fabrication Challenges

The very high melting point of quartz makes it much more difficult to work with. Shaping, blowing, and repairing quartz require specialized equipment and highly skilled technicians, further adding to the overall cost.

Brittleness and Chemical Resistance

While it excels at resisting thermal shock, quartz is still a brittle material and is susceptible to breaking from mechanical impact. Furthermore, it is attacked and etched by hydrofluoric acid (HF) and hot, strong alkaline solutions like potassium hydroxide (KOH).

Making the Right Choice for Your Application

Selecting the correct material requires balancing performance needs against practical constraints.

- If your primary focus is high-temperature processing (>800°C) or extreme purity: Quartz is the essential and often only choice.

- If your primary focus is UV transparency (below 350 nm): You must use quartz or another UV-grade transparent material.

- If your primary focus is general lab work under 500°C with no UV requirements: Borosilicate glass is the more practical and cost-effective option.

- If your primary focus is budget: Use borosilicate glass unless the extreme properties of quartz are an absolute technical requirement for your process to succeed.

Understanding these material properties empowers you to select the right tool for your specific scientific or industrial goal.

Summary Table:

| Property | Quartz Tube | Borosilicate Glass |

|---|---|---|

| Max Continuous Temp | >1000°C | ~500°C |

| UV Transparency | Excellent (below 350nm) | Poor |

| Chemical Purity | High (ideal for semiconductors) | Good |

| Thermal Shock Resistance | Excellent | Good |

| Cost | High | Lower |

Need a high-performance quartz tube for your lab? KINTEK specializes in precision lab equipment and consumables, including quartz tubes designed for extreme temperatures, chemical inertness, and UV transparency. Whether you're in semiconductor manufacturing, materials research, or UV applications, our products ensure reliability and purity. Contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis