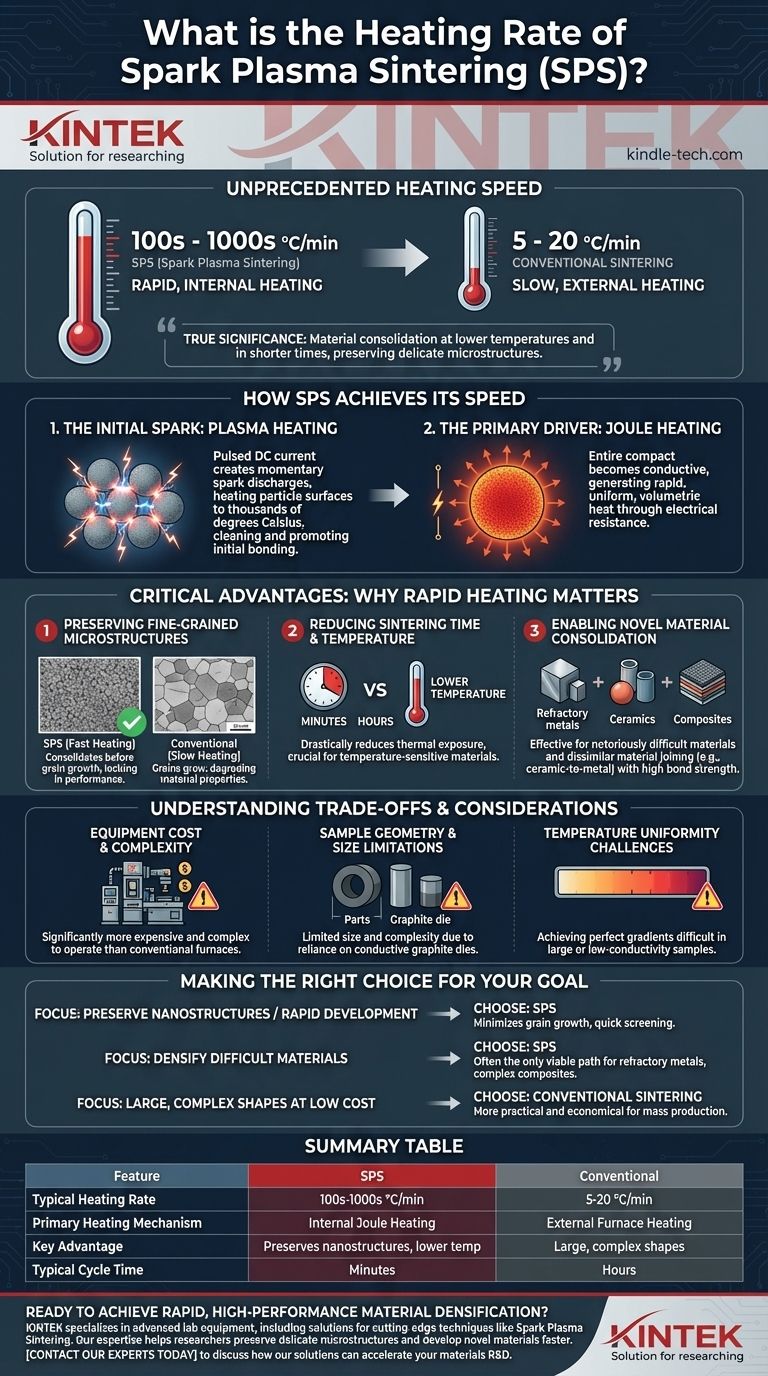

In short, the heating rate of spark plasma sintering (SPS) is exceptionally high. While conventional furnaces heat at rates of 5-20°C per minute, SPS can achieve heating rates of hundreds or even thousands of degrees Celsius per minute, enabling a full sintering cycle to be completed in a fraction of the time.

The true significance of the rapid heating in SPS is not just speed, but how it fundamentally changes the sintering process. This unique heating mechanism allows for material consolidation at lower overall temperatures and in shorter times, which is critical for preserving delicate, high-performance microstructures that would otherwise be destroyed.

How SPS Achieves Its Unprecedented Heating Speed

The rapid heating is not a feature of an external furnace but is generated directly within the material itself. This is accomplished through a combination of two distinct heating mechanisms.

The Initial Spark: Plasma Heating

The process begins by passing a pulsed DC current through the conductive die and the powder compact. At the points of contact between individual powder particles, the electrical resistance is high, generating momentary spark discharges.

These sparks create localized and momentary plasma, heating the surfaces of the particles to temperatures of several thousand degrees Celsius. This intense, brief heating purifies and activates the particle surfaces, vaporizing impurities and promoting the initial formation of "necks" that bond particles together.

The Primary Driver: Joule Heating

Once the initial contacts are established, the entire powder compact becomes more conductive. The primary heating mechanism then transitions to Joule heating.

This is the same principle that causes a wire to get hot when electricity passes through it. The electrical resistance of the powder compact as a whole generates rapid, uniform, and volumetric heat throughout the material.

The Critical Advantage: Why Rapid Heating Matters

The speed of SPS is a means to an end. The rapid heating and short processing times unlock significant material science advantages that are unattainable with conventional sintering methods.

Preserving Fine-Grained Microstructures

Many advanced materials derive their superior properties from extremely small, or nano-sized, grain structures. In slow, conventional heating, these grains have time to grow larger, which can degrade the material's final properties.

Because SPS is so fast, it consolidates the powder into a dense solid before the grains have a chance to grow. This allows it to preserve the refined microstructures created by processes like cryogenic milling, locking in the desired performance.

Reducing Sintering Time and Temperature

The localized superheating at particle surfaces allows for effective bonding and densification at a much lower overall bulk temperature compared to traditional methods.

Combining a lower required temperature with a cycle time of minutes instead of hours drastically reduces the thermal exposure of the material. This is crucial for temperature-sensitive or reactive materials.

Enabling Novel Material Consolidation

The unique heating mechanism makes SPS exceptionally effective for materials that are notoriously difficult to sinter. This includes refractory metals, certain ceramics, and gradient composite materials.

Furthermore, the process enhances self-diffusion, enabling the direct joining or "welding" of dissimilar materials, such as ceramic-to-metal, with high bond strength.

Understanding the Trade-offs and Considerations

While powerful, SPS is not a universal solution. Understanding its limitations is key to using it effectively.

Equipment Cost and Complexity

Spark plasma sintering systems are significantly more expensive and complex to operate and maintain than the conventional furnaces used for traditional sintering.

Sample Geometry and Size Limitations

The process relies on a conductive graphite die to contain the powder and conduct the current. This inherently limits the size and complexity of the parts that can be produced, with simple cylindrical shapes being the most common.

Temperature Uniformity Challenges

While heating is generally uniform, achieving perfect thermal gradients can be difficult in larger samples or materials with very low electrical conductivity. This can lead to slight variations in density or microstructure within a single part.

Making the Right Choice for Your Goal

SPS is a specialized tool best applied to specific challenges. Use this guide to determine if it fits your objective.

- If your primary focus is preserving nanostructures or fine grains: SPS is the superior choice, as it minimizes the grain growth that plagues slower methods.

- If your primary focus is rapid material development: The incredibly short cycle time of SPS makes it an ideal tool for quickly screening new compositions and formulations.

- If your primary focus is densifying difficult materials: For refractory metals, covalent ceramics, or complex composites that fail to densify with conventional methods, SPS is often the only viable path.

- If your primary focus is producing large, complex shapes at low cost: Traditional powder metallurgy and furnace sintering remain the more practical and economical option.

Ultimately, spark plasma sintering empowers you to create advanced materials that are simply not possible with conventional techniques.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Typical Heating Rate | 100s - 1000s °C/min | 5 - 20 °C/min |

| Primary Heating Mechanism | Internal Joule Heating | External Furnace Heating |

| Key Advantage | Preserves nanostructures, lower sintering temperature | Suitable for large, complex shapes |

| Typical Cycle Time | Minutes | Hours |

Ready to achieve rapid, high-performance material densification?

KINTEK specializes in advanced lab equipment, including solutions for cutting-edge techniques like Spark Plasma Sintering. Our expertise helps researchers and engineers like you preserve delicate microstructures and develop novel materials faster.

Contact our experts today to discuss how our solutions can accelerate your materials R&D.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is the SPS system? A Guide to Special Protection Systems vs. Spark Plasma Sintering

- What are the different types of hot pressing? Uniaxial, HIP, and SPS Explained

- How does a vacuum hot press sintering furnace facilitate a high-quality bond? Achieve Superior Metallurgical Coating

- What processing conditions does a vacuum hot press furnace provide? Optimize GNPs-Cu/Ti6Al4V Fabrication

- How do graphite molds function within the vacuum hot pressing process for ZnS? Optimize Densification & Optical Clarity

- What technical advantages does a vacuum hot press furnace offer? Achieve Superior Densification in Al-Si Composites

- Why apply 30-50 MPa in Vacuum Hot Pressing? Achieve 100% Density and Void-Free Composite Bonding

- What is the function of a VHPS system in CoCrFeNiMn alloys? Achieve Near-Theoretical Density and High Purity