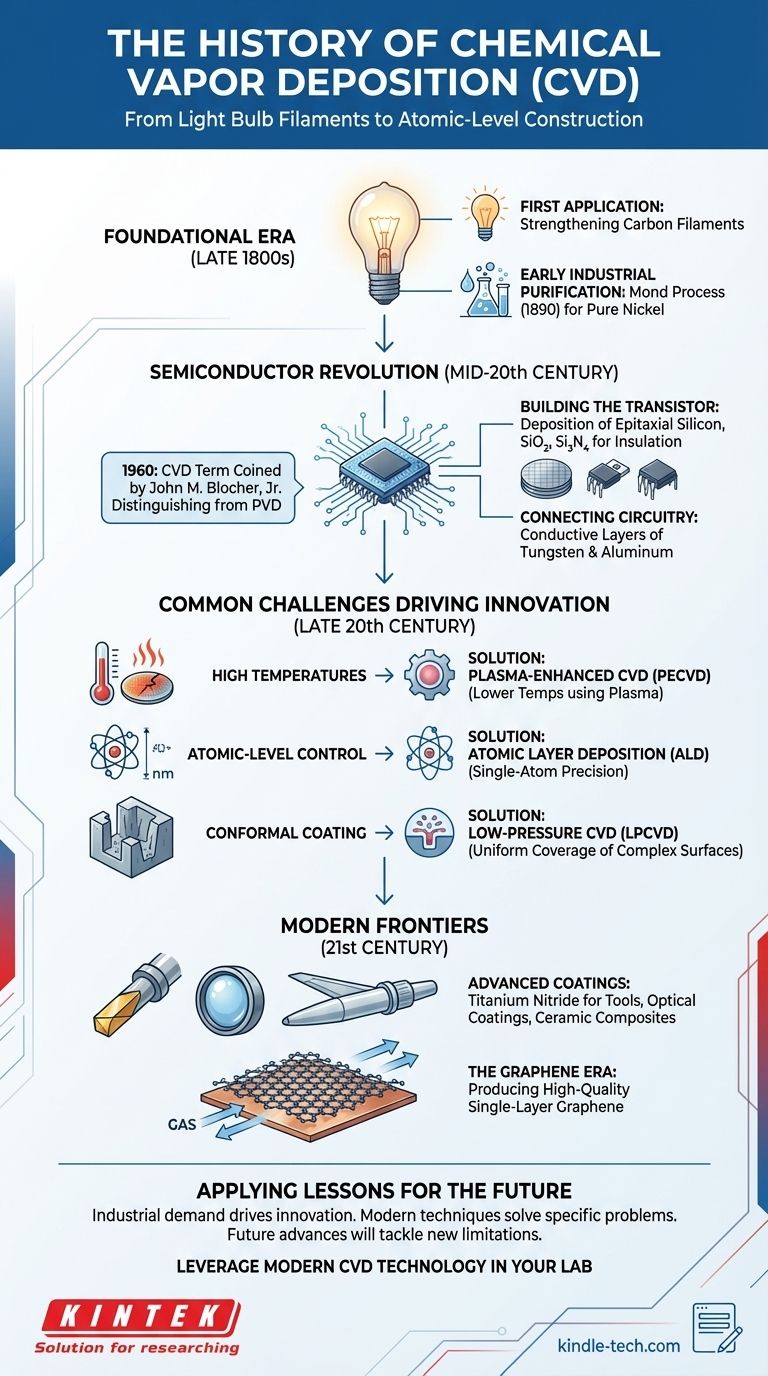

The history of chemical vapor deposition (CVD) reveals a technology whose core principles were observed over a century ago but were only formally defined and rapidly advanced with the dawn of the semiconductor age. While the term was coined by John M. Blocher, Jr. in 1960 to distinguish it from physical methods, its roots trace back to early experiments with incandescent light bulbs in the late 19th century.

The evolution of CVD is a clear story of a scientific principle being transformed by industrial necessity. It grew from a niche technique for simple coatings into the atomic-level construction tool that underpins virtually all modern electronics and advanced materials.

The Foundational Era: Early Discoveries

The fundamental concept of using a chemical reaction in a gaseous state to create a solid deposit has been in practice far longer than the formal name has existed.

The First Application: Light Bulb Filaments

In the late 1800s, innovators working on the incandescent light bulb faced the challenge of brittle carbon filaments. They discovered that heating these filaments in a hydrocarbon gas atmosphere would decompose the gas, depositing a layer of carbon that significantly increased the filament's strength and lifespan. This was, in essence, the first major industrial use of CVD.

Early Industrial Purification

Around the same time, the Mond process was developed in 1890 to refine nickel. This process involved reacting impure nickel with carbon monoxide to form a volatile gas (nickel carbonyl), which was then decomposed by heat in a separate chamber to deposit ultra-pure nickel. This demonstrated the power of CVD for creating materials of exceptionally high purity.

The Semiconductor Revolution: A New Demand for Precision

The mid-20th century marked the most critical turning point in CVD's history. The rise of the electronics industry created a demand that only CVD could meet.

A Formal Definition

In 1960, John M. Blocher, Jr. officially proposed the term Chemical Vapor Deposition. This act was crucial, as it formally established CVD as a distinct field of materials science, separating it from Physical Vapor Deposition (PVD), which involves processes like evaporation or sputtering.

Building the Transistor

The development of the integrated circuit required the ability to lay down incredibly thin, pure, and uniform layers of different materials. CVD became the go-to method for depositing the epitaxial silicon that forms the foundation of a microchip, as well as the silicon dioxide and silicon nitride films used for insulation.

Connecting the Circuitry

As circuits became more complex, CVD was also adapted to deposit conductive layers. Techniques were developed to deposit metals like tungsten and aluminum, which serve as the microscopic wiring connecting the millions of transistors on a single chip.

Common Challenges That Drove Innovation

The history of CVD is not just one of success, but also of overcoming fundamental limitations. These challenges were the primary catalysts for the development of more advanced CVD techniques.

The Problem of High Temperatures

Traditional CVD processes require very high temperatures to drive the necessary chemical reactions. This heat can damage or alter the delicate, pre-existing layers on a semiconductor wafer. This limitation directly led to the invention of Plasma-Enhanced CVD (PECVD), which uses an energy-rich plasma to allow deposition to occur at much lower, safer temperatures.

The Pursuit of Atomic-Level Control

As electronic components shrank to the nanometer scale, manufacturers needed to control film thickness with single-atom precision. This seemingly impossible demand spurred the development of Atomic Layer Deposition (ALD), a sub-class of CVD where precursor gases are pulsed into the chamber one at a time, allowing for the growth of a material one perfect atomic layer at a time.

The Need for Conformal Coating

Early CVD methods struggled to evenly coat the complex, three-dimensional trenches and structures of a modern microchip. This led to the creation of Low-Pressure CVD (LPCVD), a technique that improves the ability of precursor gases to reach and coat all surfaces uniformly, ensuring no gaps or defects.

Modern Frontiers: Beyond Electronics

While its development was driven by electronics, the applications of CVD have expanded dramatically into nearly every field of engineering and materials science.

Advanced Coatings and Materials

Today, CVD is used to apply ultra-hard titanium nitride coatings to cutting tools, create scratch-resistant optical coatings for lenses, and manufacture high-performance ceramic composites for the aerospace industry.

The Graphene Era

More recently, CVD has become the leading method for producing large, high-quality, single-layer sheets of graphene. By flowing methane gas over a heated copper foil, researchers can grow uniform graphene films, unlocking the material's potential for next-generation electronics, sensors, and composites.

Applying These Historical Lessons

Understanding the evolution of CVD provides a clear framework for appreciating its role in technology today.

- If your primary focus is process selection: Recognize that modern techniques like PECVD and ALD were developed to solve specific problems (heat and precision) inherent in older methods.

- If your primary focus is materials science: Note that industrial demand, particularly from the semiconductor sector, has been the single greatest driver of innovation in thin-film deposition.

- If your primary focus is future development: Understand that the next great advance in deposition technology will likely arise from a fundamental limitation encountered in producing tomorrow's technology.

CVD's journey from strengthening a simple filament to building the most complex devices known to humanity is a testament to its unparalleled versatility and control.

Summary Table:

| Era | Key Development | Impact |

|---|---|---|

| Late 1800s | Strengthening carbon filaments in light bulbs | First industrial use of CVD principles |

| 1890 | Mond process for nickel purification | Demonstrated CVD's ability to create high-purity materials |

| 1960 | Term "CVD" coined by John M. Blocher, Jr. | Formalized the field, distinguishing it from PVD |

| Mid-20th Century | Deposition of epitaxial silicon, SiO₂, Si₃N₄ for semiconductors | Became foundational to the integrated circuit and electronics industry |

| Late 20th Century | Development of PECVD, LPCVD, ALD | Solved challenges of high temperature, conformality, and atomic-level precision |

| 21st Century | Production of graphene and advanced coatings | Expanded into new materials for electronics, aerospace, and optics |

Ready to leverage the precision of modern CVD technology in your lab?

The history of CVD shows how solving material deposition challenges drives innovation. KINTEK specializes in providing the advanced lab equipment and consumables needed for cutting-edge research and production. Whether you are developing next-generation semiconductors, graphene-based devices, or high-performance coatings, we have the solutions to support your work.

Contact us today to discuss how our expertise can enhance your laboratory's capabilities. Let's build the future of materials science together. Get in touch via our contact form

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings