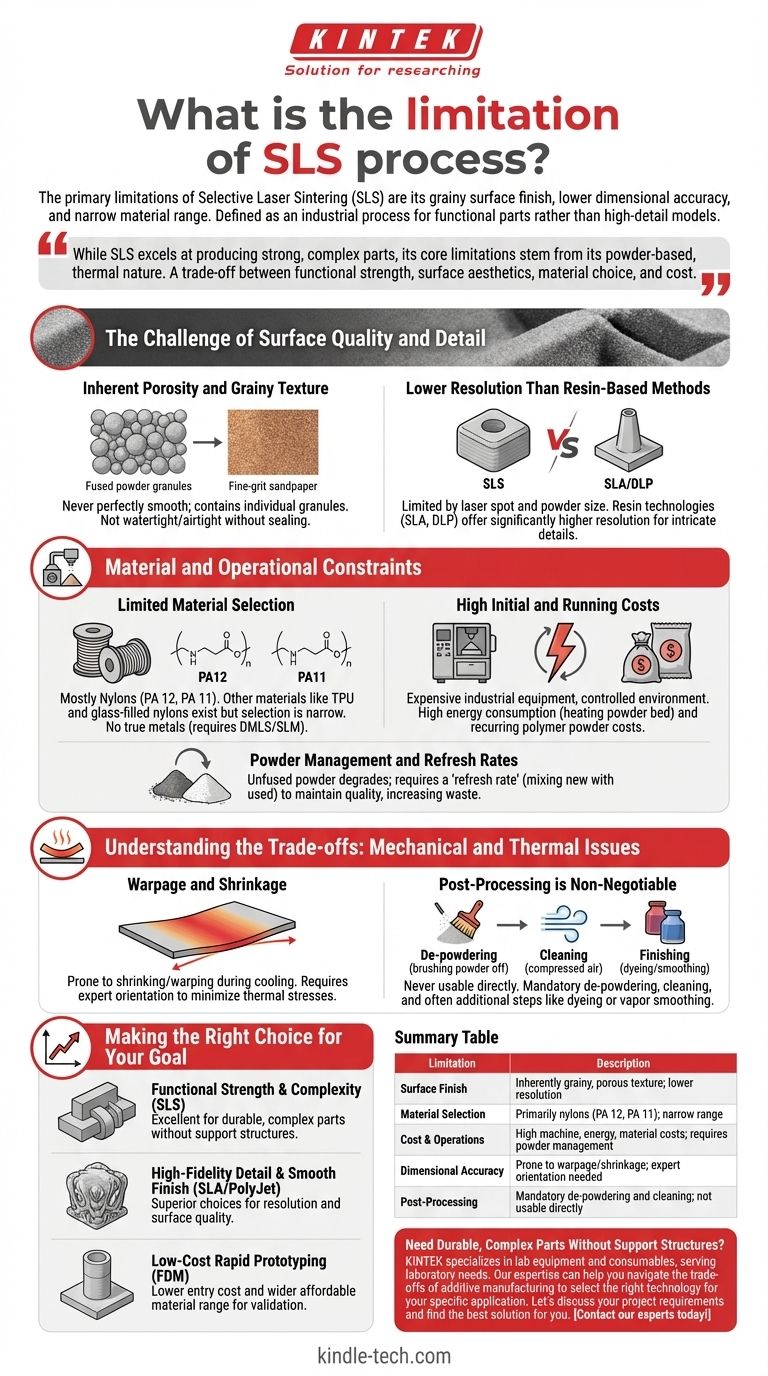

The primary limitations of Selective Laser Sintering (SLS) are its grainy surface finish, lower dimensional accuracy compared to other methods, and a relatively narrow range of available materials. These factors, combined with high operational costs and the necessity for post-processing, define its use case as an industrial process for functional parts rather than high-detail aesthetic models.

While SLS excels at producing strong, geometrically complex parts without support structures, its core limitations stem from its powder-based, thermal nature. A project's success depends on accepting a trade-off between functional strength and surface aesthetics, material choice, and cost.

The Challenge of Surface Quality and Detail

The most immediately noticeable limitation of SLS is the quality of the finished part's surface. This is a direct result of the core printing process.

Inherent Porosity and Grainy Texture

SLS works by partially melting and fusing polymer powder particles together. The final surface is never perfectly smooth because it is composed of these individual granules, leaving a texture similar to fine-grit sandpaper.

This inherent porosity also means that standard SLS parts are not watertight or airtight without a secondary sealing process.

Lower Resolution Than Resin-Based Methods

The precision of an SLS part is limited by the laser's spot size and the size of the powder particles.

For applications requiring razor-sharp edges, micro-features, or intricate textures, resin-based technologies like Stereolithography (SLA) or Digital Light Processing (DLP) offer significantly higher resolution.

Material and Operational Constraints

Unlike more common 3D printing methods, SLS is a specialized industrial process with significant operational demands that limit its accessibility and material options.

Limited Material Selection

The vast majority of SLS printing is done with nylons, primarily PA 12 and PA 11. While other materials like TPU (for flexibility) and glass-filled nylons (for stiffness) exist, the selection is narrow compared to the vast polymer libraries available for FDM or SLA.

True metals cannot be printed with SLS; that requires a different technology called Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM).

High Initial and Running Costs

SLS machines are expensive industrial equipment requiring a controlled environment. The energy consumption is high, as the entire powder bed must be heated to just below its melting point for the duration of the print.

Furthermore, the polymer powder itself is a significant recurring cost.

Powder Management and Refresh Rates

Not all of the unfused powder in the print bed can be reused indefinitely. It degrades from prolonged exposure to heat.

To maintain part quality, a "refresh rate" is required, meaning a specific percentage of used powder must be mixed with new, virgin powder for the next print. This adds to material cost and waste.

Understanding the Trade-offs: Mechanical and Thermal Issues

The thermal nature of the SLS process introduces mechanical challenges that must be accounted for during both design and production.

Warpage and Shrinkage

As the sintered parts cool from a high temperature, they are prone to shrinking and warping. This is especially problematic for large, flat parts.

Experienced operators must carefully orient parts within the build volume to minimize these thermal stresses and ensure dimensional accuracy.

Post-Processing is Non-Negotiable

SLS parts are never usable directly out of the printer. The first step is "de-powdering," where the part is excavated from the surrounding powder cake.

This is followed by cleaning with compressed air or bead blasting to remove all residual powder. For many applications, parts then require additional steps like dyeing, vapor smoothing for a sealed surface, or painting.

Making the Right Choice for Your Goal

The key is to align the known limitations of SLS with the non-negotiable requirements of your project.

- If your primary focus is functional strength and geometric complexity: The grainy surface is a minor trade-off for producing durable, complex parts like enclosures, living hinges, or interlocking assemblies without support structures.

- If your primary focus is high-fidelity detail and a smooth finish: Technologies like SLA or PolyJet are superior choices, as SLS cannot match their resolution or surface quality directly from the printer.

- If your primary focus is low-cost rapid prototyping: FDM printing offers a much lower cost of entry and a wider range of affordable materials for early-stage design validation.

Understanding these limitations allows you to leverage SLS as a powerful industrial tool for the right applications, rather than a universal solution.

Summary Table:

| Limitation | Description |

|---|---|

| Surface Finish | Inherently grainy, porous texture; lower resolution than resin-based methods. |

| Material Selection | Primarily limited to nylons (PA 12, PA 11); narrow range compared to FDM/SLA. |

| Cost & Operations | High machine, energy, and material costs; requires careful powder management. |

| Dimensional Accuracy | Prone to warpage and shrinkage due to thermal process; requires expert part orientation. |

| Post-Processing | Mandatory de-powdering and cleaning; not usable directly from the printer. |

Need Durable, Complex Parts Without Support Structures?

While SLS has its limitations, it's an unparalleled technology for producing strong, functional prototypes and end-use parts with complex geometries.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise can help you navigate the trade-offs of additive manufacturing to select the right technology for your specific application, ensuring optimal performance and cost-efficiency.

Let's discuss your project requirements and find the best solution for you. Contact our experts today!

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Small Injection Molding Machine for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- What products are blown film extrusion? From Grocery Bags to Industrial Sheeting

- What are the advantages of blown film extrusion? Boost Your Film Production Efficiency

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What is the blown film extrusion technique? Mastering Biaxial Orientation for Superior Film Strength