While there is no universal "maximum PSI" for all hydraulic presses, the operating pressure is a design-specific variable. A typical industrial press may operate between 2,000 to 10,000 PSI (pounds per square inch), but this figure is determined by the machine's intended application, components, and required output force, not by a universal technological limit.

The critical concept to understand is that the force a press exerts (its tonnage) is a product of its internal hydraulic pressure (PSI) and the area of its piston. Therefore, focusing on a press's tonnage rating is a far more practical measure of its capability than its internal PSI alone.

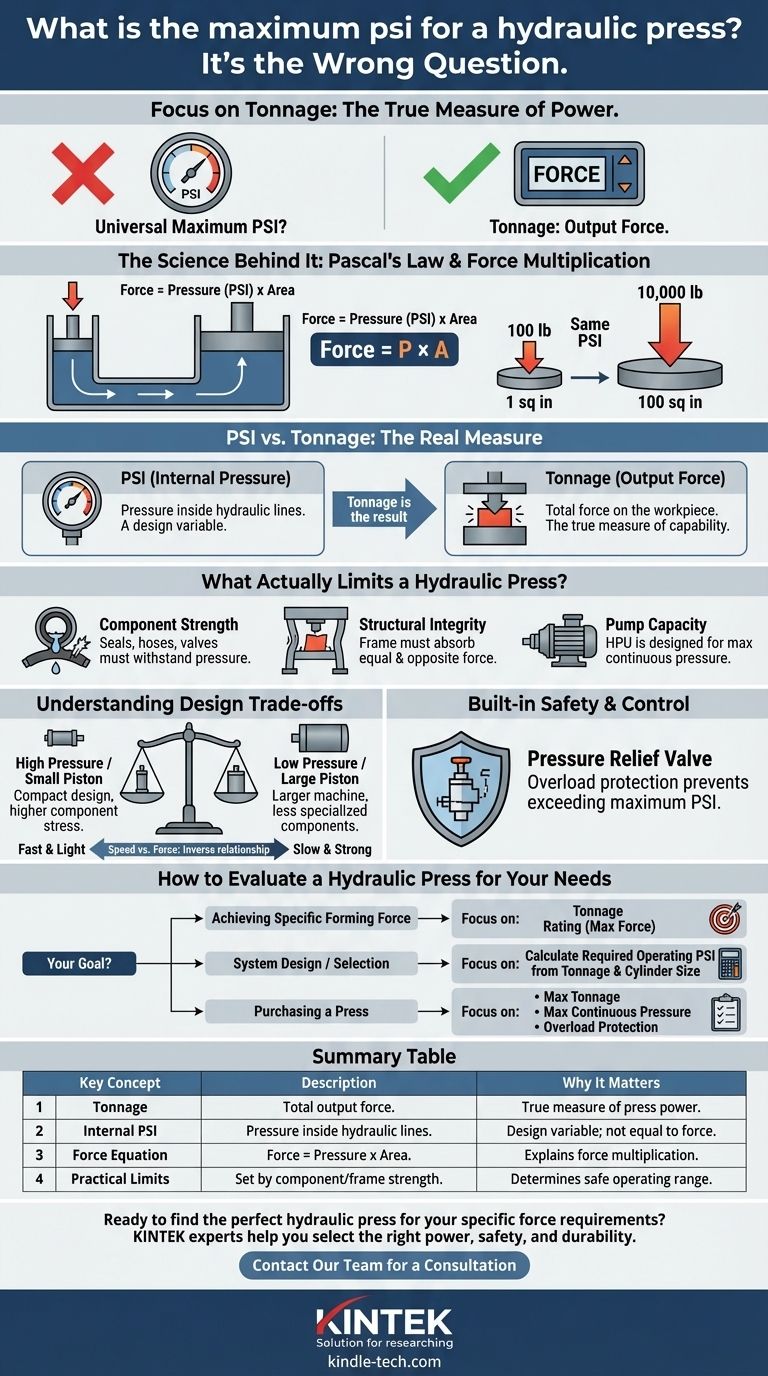

Why "Maximum PSI" Is the Wrong Question

Thinking in terms of a single maximum PSI can be misleading. The power of a hydraulic press comes from a fundamental principle of fluid dynamics, which allows for a wide range of designs.

The Foundation: Pascal's Law

A hydraulic press operates on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small amount of force on a small piston creates pressure in the hydraulic fluid. This pressure then acts on a much larger piston, multiplying the initial force significantly.

Force = Pressure (PSI) x Area

This equation is the key. A system with relatively low PSI can produce enormous force if the piston's surface area is large enough.

PSI vs. Tonnage: The Real Measure of Power

It's crucial to distinguish between the pressure within the system and the force it delivers.

- PSI (Pounds per Square Inch) is the measure of pressure inside the hydraulic lines and cylinder.

- Tonnage is the total output force the press can exert on the workpiece. This is the number that truly defines the machine's power.

A 20-ton press and a 2,000-ton press might even operate at the same internal PSI. The difference in their output force comes from the vastly different sizes of their pistons and the overall scale of their construction.

What Actually Limits a Hydraulic Press?

The theoretical limits of hydraulic pressure are extremely high, but a press is a complex system. Its practical limitations are determined by the weakest link in its design.

Component Strength

Every component must withstand the system's operating pressure. The limits are often set by the pressure ratings of:

- Seals: Prevent fluid from leaking past the piston. High pressure places immense stress on seals, and failure leads to a loss of force and potential safety hazards.

- Hoses and Fittings: Hydraulic hoses are rated for specific maximum pressures. Exceeding this can cause them to burst.

- Cylinders and Valves: The cylinder walls and control valves are engineered to a specific proof stress. Pushing past this limit risks catastrophic failure.

Structural Integrity

The frame of the press must safely absorb the equal and opposite force generated by the ram. A press rated for 100 tons must have a frame capable of withstanding that force without deforming or failing. Using a press beyond its rated tonnage can permanently damage the frame.

Pump Capacity

The hydraulic power unit (HPU) is the heart of the press. The pump is designed to generate a maximum pressure and a specific flow rate. While some pumps can spike to higher pressures, their continuous-duty rating is the true operational limit.

Understanding the Trade-offs

Engineers make specific design choices based on the intended application, which involves balancing competing factors.

Pressure vs. Piston Size

For a given tonnage requirement, a designer can choose between a high-pressure/small-piston system or a low-pressure/large-piston system.

- High-Pressure Systems: Allow for more compact cylinders and a smaller machine footprint. However, they require more robust and expensive components (seals, hoses, valves) to handle the stress.

- Low-Pressure Systems: Require larger, heavier cylinders to achieve the same force. The components may be less specialized, but the overall machine can be much larger.

Speed vs. Force

The speed of the press ram is determined by the fluid flow rate from the pump. There is often an inverse relationship between speed and force. A press can be designed to move very quickly with low force or move slowly with extremely high force.

Built-in Safety and Control

Modern hydraulic presses have built-in overload protection. A pressure relief valve automatically prevents the system from exceeding its designed maximum PSI, protecting both the machine and the operator. This feature makes them exceptionally safe compared to mechanical presses, which can fail catastrophically if overloaded.

How to Evaluate a Hydraulic Press for Your Needs

Instead of searching for a "maximum PSI," focus on the specific metrics that align with your goal.

- If your primary focus is achieving a specific forming force: The press's tonnage rating is the most important specification. This tells you the maximum force the machine can apply to your workpiece.

- If your primary focus is system design or component selection: You must work backward from the required tonnage and desired cylinder size to calculate the necessary system operating PSI.

- If your primary focus is purchasing a press: Look at the manufacturer's data sheet for the maximum tonnage and the maximum continuous operating pressure, and ensure it has certified safety features like overload protection.

Focus on the required output force for your application, as this is the true measure of a hydraulic press's capability.

Summary Table:

| Key Concept | Description | Why It Matters |

|---|---|---|

| Tonnage | The total output force exerted on the workpiece (e.g., 20 tons). | The true measure of a press's power and capability for your application. |

| Internal PSI | The pressure inside the hydraulic lines and cylinder. | A design variable; high PSI doesn't always mean high force. |

| Force Equation | Force = Pressure (PSI) x Piston Area | Explains how a press multiplies force; tonnage is the result. |

| Practical Limits | Set by component strength (seals, hoses) and structural frame. | Determines the safe operating range and prevents machine failure. |

Ready to find the perfect hydraulic press for your specific force requirements?

At KINTEK, we specialize in providing robust laboratory equipment, including hydraulic presses tailored to your exact tonnage and application needs. Our experts will help you navigate beyond simple PSI numbers to select a press with the right power, safety features, and durability for your lab.

Contact our team today for a personalized consultation and discover how KINTEK's solutions can enhance your productivity and safety.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- Why was the hydraulic press important? Unlocking Unprecedented Industrial Power

- How many pounds of force does a hydraulic press have? Find Your Ideal Tonnage for Any Application

- What are the features of a hydraulic press? Unlock Immense Force with Simple, Reliable Design

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing