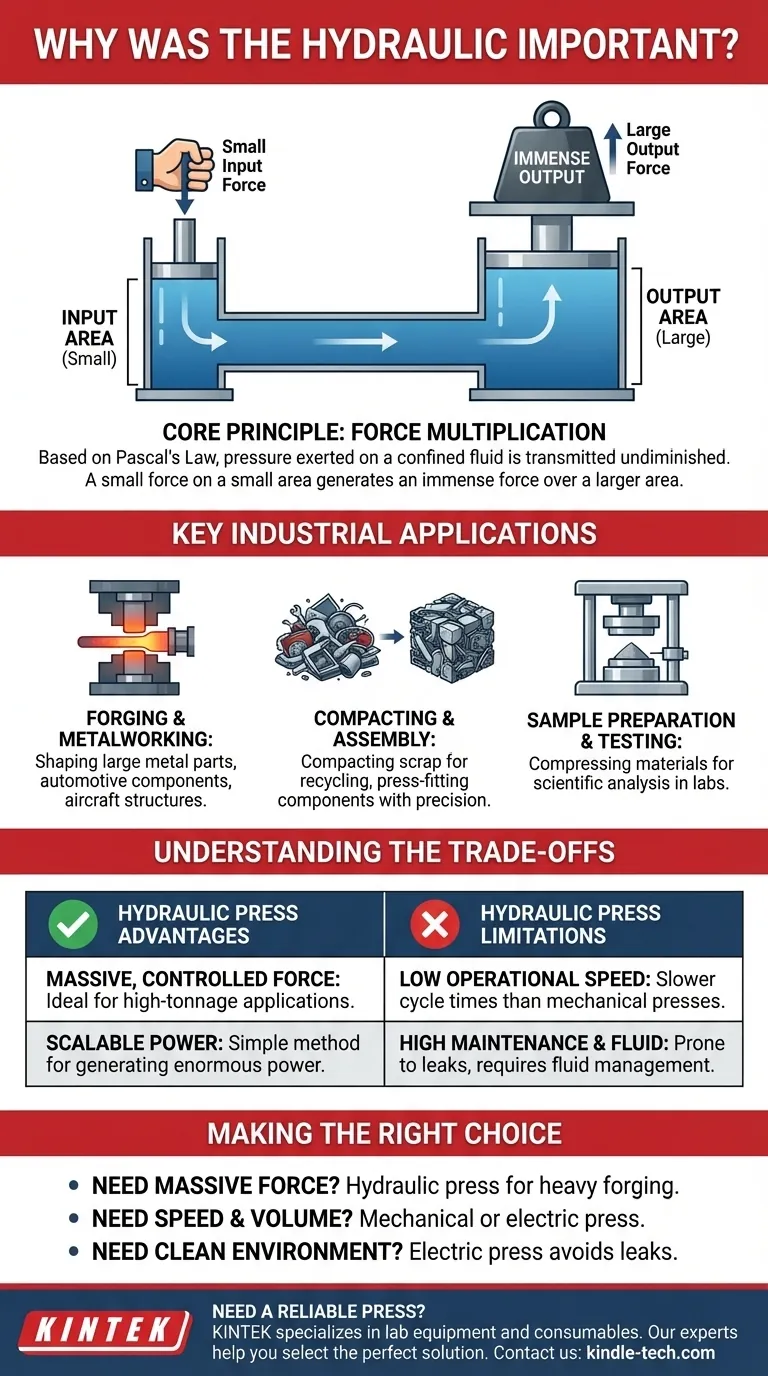

The importance of the hydraulic press stems from its unique ability to multiply force using a simple, incompressible fluid. Based on Pascal's Law, this technology allows a small, manageable input force applied to a small area to generate an immense output force over a larger area, making it possible to bend, shape, and compress materials that would otherwise be unworkable.

The hydraulic press is significant not merely as a machine, but as a direct application of fluid dynamics that acts as a force multiplier. Its invention fundamentally changed manufacturing and engineering by providing a scalable and relatively simple method for generating enormous power.

The Core Principle: Force Multiplication Explained

The genius of the hydraulic press is its elegant application of a basic law of physics. It transforms a small effort into a colossal output, a principle that became a cornerstone of modern industry.

Pascal's Law in Action

At the heart of the press is Pascal's Law, which states that pressure exerted on a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

Imagine a sealed U-shaped tube filled with oil, with a small piston on one end and a much larger piston on the other.

The Input vs. Output Equation

When you apply a small force to the small piston, you create pressure within the fluid (Pressure = Force / Area). This pressure travels equally throughout the fluid.

This same pressure now acts on the large piston. Because the large piston has a much bigger surface area, the resulting output force is proportionally magnified (Force = Pressure x Area). A tiny push becomes a powerful crush.

Why This Was a Game-Changer

Before hydraulic systems, generating extreme force required massive and complex systems of levers, gears, or screws, which had practical limits.

The hydraulic press offered a simple, reliable, and incredibly scalable way to generate tonnage previously unimaginable, unlocking new possibilities in manufacturing and construction.

Key Industrial Applications

The ability to generate controlled, immense force made the hydraulic press indispensable across numerous sectors. Its impact is still felt in almost every heavy industry today.

Forging and Metalworking

Hydraulic presses are essential for shaping and forging large metal parts, from automotive chassis components to aircraft structural elements. Their slow, powerful, and controlled stroke is ideal for deforming thick metal billets.

Compacting and Assembly

These presses are used for compacting scrap metal into dense bales, making recycling far more efficient. They are also used for "press-fitting" components, like forcing a bearing onto a shaft with immense precision and power.

Sample Preparation and Testing

In scientific and quality control settings, smaller hydraulic presses are used to compress powdered materials into solid pellets or thin films for analysis, a direct application mentioned for modern lab equipment.

Understanding the Trade-offs

Despite its power, the hydraulic press is not the ideal solution for every application. Its design comes with inherent limitations and operational costs that must be considered.

Low Operational Speed

The movement of fluid to build up pressure is a relatively slow process. For high-speed, repetitive tasks, mechanical or electric presses often provide much faster cycle times.

High Energy Consumption

Maintaining high pressure and cycling the hydraulic fluid requires significant energy. This can lead to higher operational costs compared to purely mechanical systems.

Maintenance and Fluid Management

Hydraulic systems are prone to leaks, which can create safety hazards and environmental concerns. The hydraulic fluid itself can be flammable and requires regular filtering and replacement, adding to the maintenance burden.

Making the Right Choice for Your Application

Selecting the right type of press depends entirely on balancing the need for force with requirements for speed, precision, and maintenance.

- If your primary focus is generating massive, controlled force: A hydraulic press is often the only viable option for high-tonnage applications like heavy forging or large-scale compacting.

- If your primary focus is speed and high-volume production: A mechanical or servo-electric press is likely a better choice due to its faster cycle times and lower energy use per part.

- If your primary focus is a clean, low-maintenance environment: An electric press avoids the risks of fluid leaks and the ongoing maintenance associated with hydraulic systems.

Ultimately, understanding the hydraulic press is understanding how a simple physical law unlocked unprecedented industrial power.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Core Principle | Applies Pascal's Law to multiply a small input force into a massive output force. |

| Primary Advantage | Generates immense, controlled tonnage for bending, shaping, and compressing tough materials. |

| Key Applications | Forging metal parts, compacting scrap for recycling, and scientific sample preparation. |

| Main Limitation | Slower operational speed and higher maintenance compared to mechanical or electric presses. |

Need a reliable press for your lab or production line?

KINTEK specializes in lab equipment and consumables, offering a range of presses tailored to your specific needs. Whether you require the immense force of a hydraulic system for sample preparation or a cleaner, faster electric alternative, our experts can help you select the perfect solution to enhance your efficiency and precision.

Contact us today to discuss your application and find the right press for you!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the function of a laboratory hydraulic press in the preparation of bulk tungsten? Achieve High Density Solids

- What is KBr disc method in IR spectroscopy? A Guide to Solid Sample Analysis

- What makes a press hydraulic? The Power of Fluid Mechanics for Unmatched Force

- Why is a laboratory hydraulic press used to apply 510 MPa for Li3PS4 and Na3PS4? Achieve Optimal Electrolyte Density

- What happens when a hydraulic system overheats? Prevent Costly Damage and Downtime

- How do desired diamond color and size influence the HPHT process? Balancing Growth Rates and Mechanical Stability

- What function does a laboratory hydraulic press serve in the preparation of LLZTO ceramic electrolyte pellets?

- What is the XRF method of preparation? Ensure Accurate Elemental Analysis with Proper Sample Prep