The weight of a hydraulic press varies dramatically, scaling directly with its power. A small benchtop press used for workshop tasks might weigh as little as 20 kg (about 44 lbs), as seen in some specifications. However, massive industrial presses used for forging or manufacturing can weigh many hundreds of tons.

The essential takeaway is that a press's weight is not an arbitrary number; it is a direct consequence of its design purpose. The machine's frame must be heavy and strong enough to safely contain the immense forces it generates.

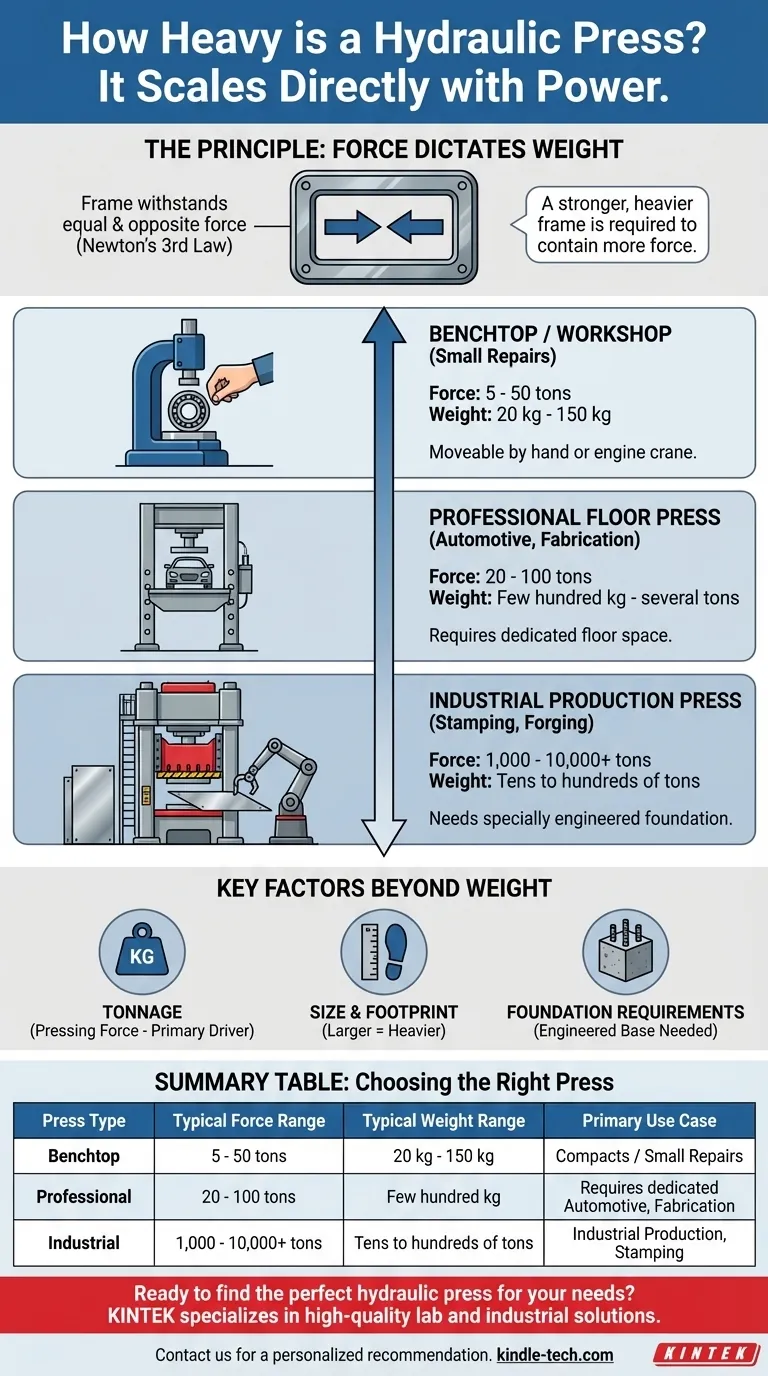

The Principle: Why Force Dictates Weight

A hydraulic press operates by using a hydraulic cylinder to generate a large compressive force. The machine's frame must withstand this exact same force trying to push it apart. This fundamental principle of physics (Newton's Third Law) is the primary driver of a press's weight.

The Frame as a Force Container

Think of the press's frame as a container for force. A stronger, thicker, and heavier frame can contain more force without deforming or failing catastrophically.

This is why a press rated for 10 tons of force is significantly lighter than one rated for 1,000 tons. The latter requires an exponentially larger and more robust steel structure to handle the load.

Benchtop and Workshop Presses

For smaller applications, like pressing bearings or for use in a home garage, presses are relatively lightweight. The 20 kg press mentioned in the technical data is a perfect example of this category.

These presses typically range from 20 kg to a few hundred kilograms and can often be moved with an engine crane or by a few people. Their force capacity is usually between 5 and 50 tons.

Industrial Production Presses

At the other end of the spectrum are industrial presses used for applications like automotive stamping, aerospace component forging, or large-scale molding.

These machines can exert thousands or even tens of thousands of tons of force. To contain this energy, their frames are monumental structures of high-strength steel, with total machine weights easily reaching into the hundreds or even thousands of tons.

Understanding the Key Factors

Weight is just one part of the equation. When evaluating a hydraulic press, its weight is intrinsically linked to several other critical specifications.

Tonnage (Pressing Force)

This is the single most important factor. The tonnage, or the maximum force the press can exert, dictates the required strength and therefore the weight of the frame. The 15-ton maximum power mentioned in the specifications requires a frame that results in a 20 kg machine weight. A 150-ton press would be substantially heavier.

Physical Size and Footprint

A heavier press is almost always a larger press. The space the machine will occupy (its footprint) and the overhead clearance required (its height) are critical logistical considerations that go hand-in-hand with its weight.

Foundation Requirements

You cannot place a multi-ton industrial press on a standard concrete floor. The floor would crack and fail. Heavy presses require specially engineered, deep concrete foundations to safely distribute their static weight and absorb the dynamic forces during operation.

Making the Right Choice for Your Goal

Selecting a press starts with understanding your operational needs, which will determine the required force and, consequently, the machine's scale and weight.

- If your primary focus is small repairs or a home workshop: A benchtop or small H-frame floor press weighing between 20 kg and 150 kg will be more than sufficient.

- If your primary focus is professional automotive or fabrication work: You will likely need a floor-standing press from 20 to 100 tons, with a weight ranging from a few hundred kilograms to several tons.

- If your primary focus is heavy industrial manufacturing: You are in the realm of custom-engineered solutions weighing tens to hundreds of tons, requiring significant infrastructure planning and investment.

Ultimately, understanding that a press's weight is a function of its power empowers you to select the right tool for your specific application.

Summary Table:

| Press Type | Typical Force Range | Typical Weight Range | Primary Use Case |

|---|---|---|---|

| Benchtop / Workshop | 5 - 50 tons | 20 kg - 150 kg | Small repairs, home garage, pressing bearings |

| Professional Floor Press | 20 - 100 tons | Few hundred kg - several tons | Automotive, fabrication, professional workshops |

| Industrial Production Press | 1,000 - 10,000+ tons | Tens to hundreds of tons | Automotive stamping, aerospace forging, large-scale molding |

Ready to find the perfect hydraulic press for your specific needs?

At KINTEK, we specialize in providing high-quality lab equipment and industrial machinery, including hydraulic presses tailored for workshops, professional fabrication, and heavy industrial applications. Our experts will help you select a press with the right tonnage, footprint, and weight for your operation, ensuring safety and efficiency.

Contact us today to discuss your requirements and get a personalized recommendation. Let KINTEK be your trusted partner in powering your projects. Get in touch with our specialists now!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis