Ultimately, there is no single maximum temperature for a muffle furnace. The maximum temperature is a defining specification that varies significantly based on the furnace's design, heating elements, and intended application. While many standard laboratory models operate up to 1200°C, high-performance units can reach 1700°C, 1800°C, or in some specialized cases, even higher.

The maximum temperature of a muffle furnace is not a universal constant but a critical design parameter. It is determined by the furnace's construction—specifically its heating elements and insulation—which in turn dictates its suitability for different applications, from basic ashing to advanced materials research.

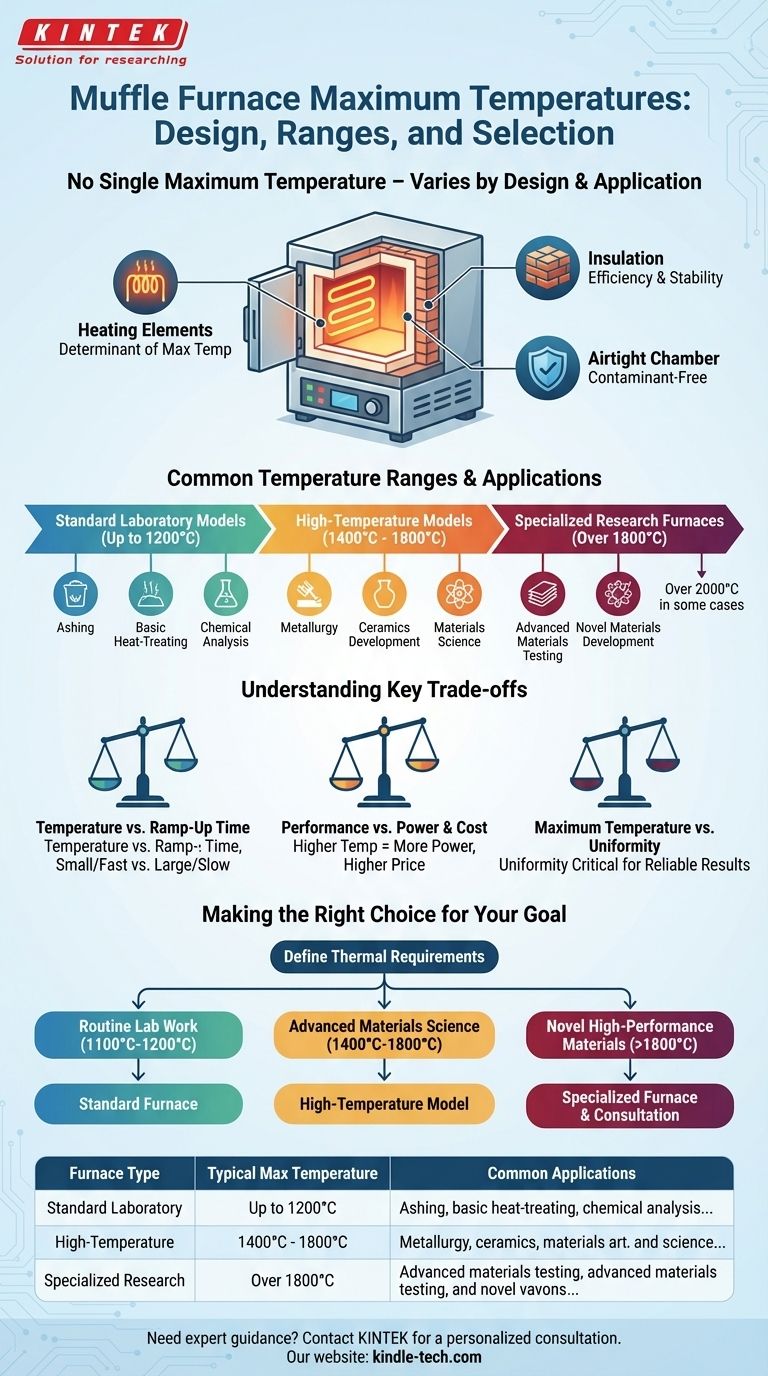

What Defines a Muffle Furnace's Maximum Temperature?

A muffle furnace's core function is to heat materials within a chamber while isolating them from the direct heat source and any potential contaminants, such as combustion byproducts. The factors that dictate its temperature ceiling are built into its fundamental design.

The Role of Heating Elements

Modern electric muffle furnaces are the most common type, offering excellent temperature control and uniformity. The material used for the electric heating elements is the primary determinant of the maximum achievable temperature. Different materials are required to reliably produce and withstand different heat levels.

The Importance of Insulation

To reach and maintain extreme temperatures efficiently, a furnace requires high-quality insulation. Materials range from low thermal mass insulation in smaller, faster-heating furnaces to dense refractory bricks in larger industrial units. The quality of this insulation dictates how well the furnace retains heat and maintains a stable, uniform temperature.

The Design Principle: A Contaminant-Free Chamber

The term "muffle" refers to the airtight inner chamber where the sample is placed. This design is crucial because it separates the material from the heating elements and atmospheric gases. This prevents contamination and unwanted chemical reactions, which is essential for precise scientific and industrial processes.

Common Temperature Ranges and Their Applications

The wide variance in maximum temperatures reflects the diverse tasks these furnaces are built for. They can be grouped into general performance tiers.

Standard Laboratory Models (Up to 1200°C)

This is the most common range for general-purpose laboratory work. Furnaces topping out at 1100°C or 1200°C are workhorses for applications like chemical analysis, ashing organic and inorganic samples, and simple heat-treating of metals.

High-Temperature Models (1400°C - 1800°C)

This category serves more demanding fields. Furnaces reaching 1400°C, 1700°C, or 1800°C are essential in metallurgy, ceramics development, materials science, and advanced research where higher thermal energy is required to alter material properties.

Specialized Research Furnaces (Over 1800°C)

A few highly specialized furnaces are designed to operate above 1800°C, with some research models even exceeding 2000°C. These are not standard equipment and are built for specific, cutting-edge applications involving high-performance materials.

Understanding the Key Trade-offs

Selecting a furnace isn't just about choosing the highest temperature. Higher performance comes with practical trade-offs that are critical to consider.

Temperature vs. Ramp-Up Time

The time it takes for a furnace to reach its maximum temperature can vary dramatically. A small lab furnace with lightweight insulation might reach 1100°C in as little as 20 minutes. In contrast, a larger, high-temperature furnace with dense refractory insulation may take several hours to safely reach its 1800°C setpoint.

Performance vs. Power and Cost

Higher maximum temperatures require more robust, exotic heating elements and thicker, more advanced insulation. This directly translates to a higher initial purchase price and significantly greater power consumption during operation.

Maximum Temperature vs. Uniformity

Simply reaching a high temperature is not enough; maintaining a uniform temperature throughout the entire chamber is critical for reliable results. High-performance models are engineered to minimize hot or cold spots, ensuring that the entire sample is processed under the same thermal conditions.

Making the Right Choice for Your Goal

To select the appropriate muffle furnace, you must first define the thermal requirements of your specific process.

- If your primary focus is routine lab work like ashing or basic heat treating: A standard furnace with a maximum temperature between 1100°C and 1200°C is the most practical and cost-effective choice.

- If your primary focus is advanced materials science, ceramics, or metallurgy: You will need to invest in a high-temperature model capable of reaching the 1400°C to 1800°C range.

- If your primary focus is creating or testing novel high-performance materials: You likely require a specialized furnace and should consult with manufacturers to find a unit that meets your specific high-temperature needs.

Choosing the right furnace means matching its capabilities directly to your application's requirements.

Summary Table:

| Furnace Type | Typical Max Temperature | Common Applications |

|---|---|---|

| Standard Laboratory | Up to 1200°C | Ashing, basic heat-treating, chemical analysis |

| High-Temperature | 1400°C - 1800°C | Metallurgy, ceramics, materials science |

| Specialized Research | Over 1800°C | Advanced materials testing and development |

Need expert guidance to select the perfect muffle furnace for your specific temperature and application requirements?

At KINTEK, we specialize in providing high-quality lab equipment, including a wide range of muffle furnaces for various laboratory needs. Our experts can help you navigate the trade-offs between temperature, cost, and performance to ensure you get a solution that delivers precise, reliable results for your work.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What are muffle furnaces used for? Achieve Precise, Contaminant-Free High-Temperature Processing

- What is the effect of temperature on calcination? Master Precise Heat Control for Material Properties

- How does the calcination process work? Master Thermal Decomposition for Material Purification

- At what temperature does quartz soften? Understand the practical limits for lab equipment