In essence, a controlled atmosphere (CA) is an agricultural storage method that actively regulates the air composition within a sealed space. By precisely managing the levels of oxygen, carbon dioxide, and nitrogen, along with temperature and humidity, it dramatically extends the shelf life of produce. This technique is used for both fresh items like fruits and vegetables and dry commodities.

The fundamental goal of a controlled atmosphere is not just to cool produce, but to slow its natural life cycle—respiration, ripening, and decay—to a near standstill. This preserves the quality, freshness, and nutritional value of food for months longer than conventional refrigeration allows.

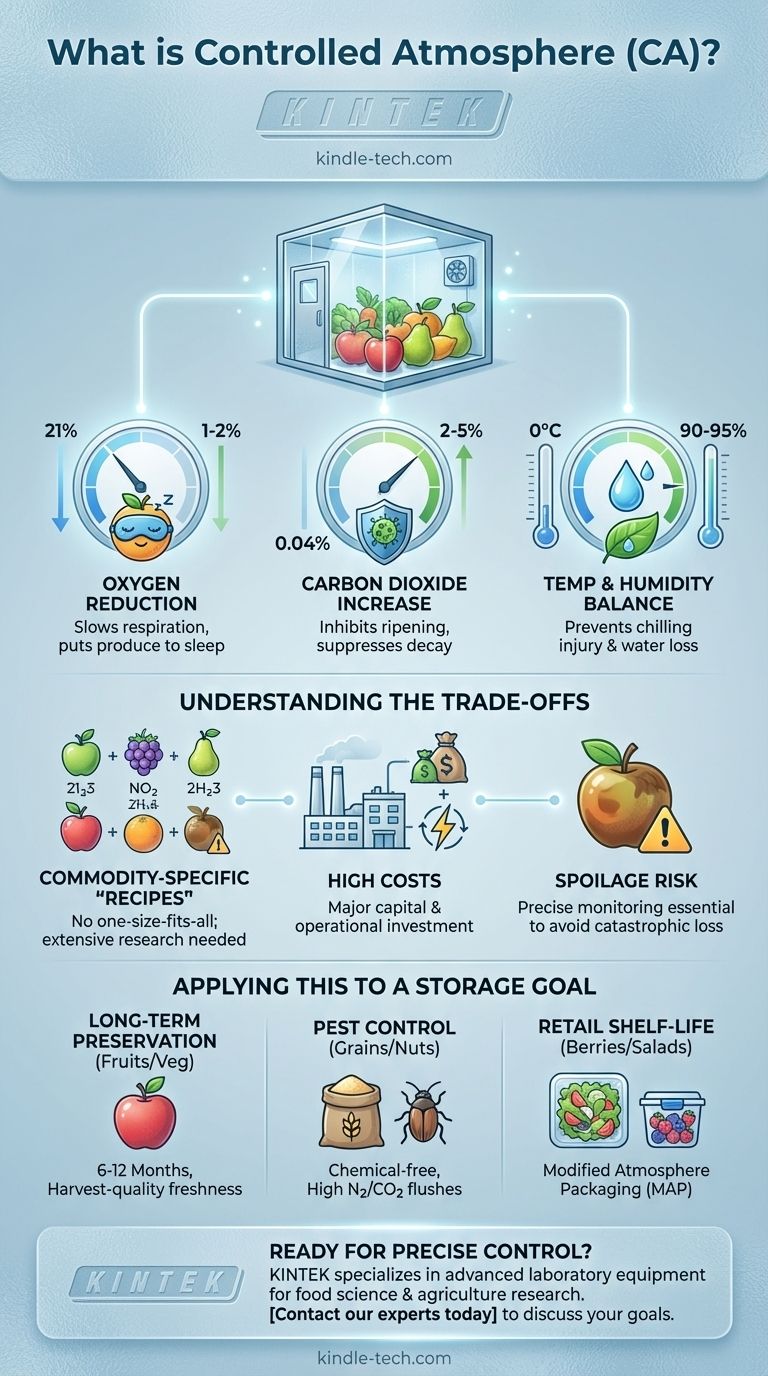

How a Controlled Atmosphere Works

A controlled atmosphere puts produce into a state of hibernation by manipulating the very air it breathes. This process hinges on managing the key elements that influence the rate of aging and decay in harvested crops.

The Critical Role of Oxygen Reduction

Once harvested, fruits and vegetables continue to "breathe" or respire, consuming oxygen and breaking down stored sugars for energy. This is the primary process that leads to ripening and eventual decay.

A CA storage facility reduces the ambient oxygen level from the normal 21% in our air to as low as 1-2%. This drastic reduction significantly slows the respiration rate, effectively putting the produce to sleep and preserving its stored sugars, firmness, and flavor.

The Function of Carbon Dioxide

While oxygen is reduced, carbon dioxide (CO2) levels are often increased. Normal air has very little CO2 (around 0.04%), but in a CA room, it might be elevated to 2-5% or higher, depending on the commodity.

Elevated CO2 acts as a further brake on the respiration and ripening processes. It can also help suppress the growth of certain molds and decay-causing pathogens, adding another layer of protection.

Balancing Temperature and Humidity

Temperature and humidity are the final pieces of the puzzle. The storage facility is kept at the lowest possible temperature that will not cause chilling injury to the specific fruit or vegetable.

High humidity (typically 90-95%) is also maintained. This prevents the produce from losing water through transpiration, which would otherwise lead to shriveling, weight loss, and a decline in quality.

Understanding the Trade-offs

While highly effective, implementing a controlled atmosphere is a significant undertaking with specific challenges. It is not a simple or universally applicable solution.

Commodity-Specific "Recipes"

There is no one-size-fits-all formula for a controlled atmosphere. Every fruit and vegetable has a unique tolerance for low oxygen and high carbon dioxide.

An apple might thrive in 2% oxygen, but the same conditions could suffocate or damage a different type of produce. Extensive research is required to determine the precise atmospheric "recipe" for each commodity to maximize storage life without causing physiological damage.

High Initial and Operational Costs

Building a CA storage facility is a major capital investment. The rooms must be completely airtight, insulated, and equipped with specialized gas generation and monitoring systems.

These systems require constant energy and precise computer control to maintain the delicate atmospheric balance, leading to significant operational costs compared to standard cold storage.

The Risk of Spoilage

If the atmospheric composition is not perfectly maintained, it can lead to catastrophic losses. Too little oxygen can cause fermentation and cell death, while incorrect CO2 levels can result in discoloration, off-flavors, or internal browning.

This makes precise monitoring and control systems absolutely essential for success.

Applying This to a Storage Goal

The decision to use a controlled atmosphere depends entirely on the specific preservation goal and the commodity being stored.

- If your primary focus is long-term preservation of high-value produce like apples or pears: A true controlled atmosphere system is the industry standard for maintaining harvest-quality freshness for 6 to 12 months.

- If your primary focus is preventing insect infestation in grains or nuts: A simplified version called a "modified atmosphere," often using high nitrogen or CO2 flushes, is a highly effective, chemical-free pest control method.

- If your primary focus is extending the shelf life of berries or salads for retail: Modified Atmosphere Packaging (MAP), which uses specialized bags or containers to trap a beneficial mix of gases, applies the same principles on a smaller scale.

Ultimately, a controlled atmosphere is a powerful scientific tool that enables us to manage the biological processes of food, reducing waste and ensuring quality from farm to consumer.

Summary Table:

| Key Aspect | Function in Controlled Atmosphere |

|---|---|

| Oxygen Level | Reduced to 1-2% to slow respiration and decay. |

| Carbon Dioxide | Increased to 2-5% to further inhibit ripening and mold. |

| Temperature & Humidity | Precisely controlled to prevent chilling injury and water loss. |

| Primary Goal | Puts produce into a state of hibernation to preserve quality for months. |

Ready to implement precise environmental control in your operations? KINTEK specializes in advanced laboratory equipment and consumables for research and quality control in food science and agriculture. Whether you are developing new storage 'recipes' or need reliable monitoring systems, our solutions help you achieve optimal results. Contact our experts today to discuss how we can support your preservation and storage goals.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- What is the necessity of a controlled atmosphere furnace for corrosion research? Replicating Realistic Industrial Risks

- How does a lab atmosphere furnace help synthesize PdCuAu alloys? Optimize Your Material Research Results

- What is an atmosphere oven? Achieve Precise Thermal Processing in a Controlled Gas Environment

- What is a reducing atmosphere? Key Applications and Benefits for Industrial Processes

- What is the role of the furnace atmosphere? Master Precise Metallurgical Control for Your Heat Treatment

- What is an atmosphere furnace? A Guide to Controlled Environment Heating

- What are the disadvantages of an inert gas system? Understanding the Safety and Operational Risks

- Why does a reducing atmosphere produce a dark firing core? Unlock the Chemistry of Ceramic Firing