Heat treatment of steel is a highly controlled process of heating and cooling the metal to deliberately alter its internal microstructure. The primary methods include annealing, hardening (quenching), tempering, and case hardening, with each process designed to achieve specific mechanical properties like ductility, hardness, or toughness for a particular application.

Heat treatment is not a single action but a set of precise metallurgical tools. By carefully controlling temperature and cooling rates, you can strategically trade one property (like extreme hardness) for another (like toughness) to engineer the steel's final performance.

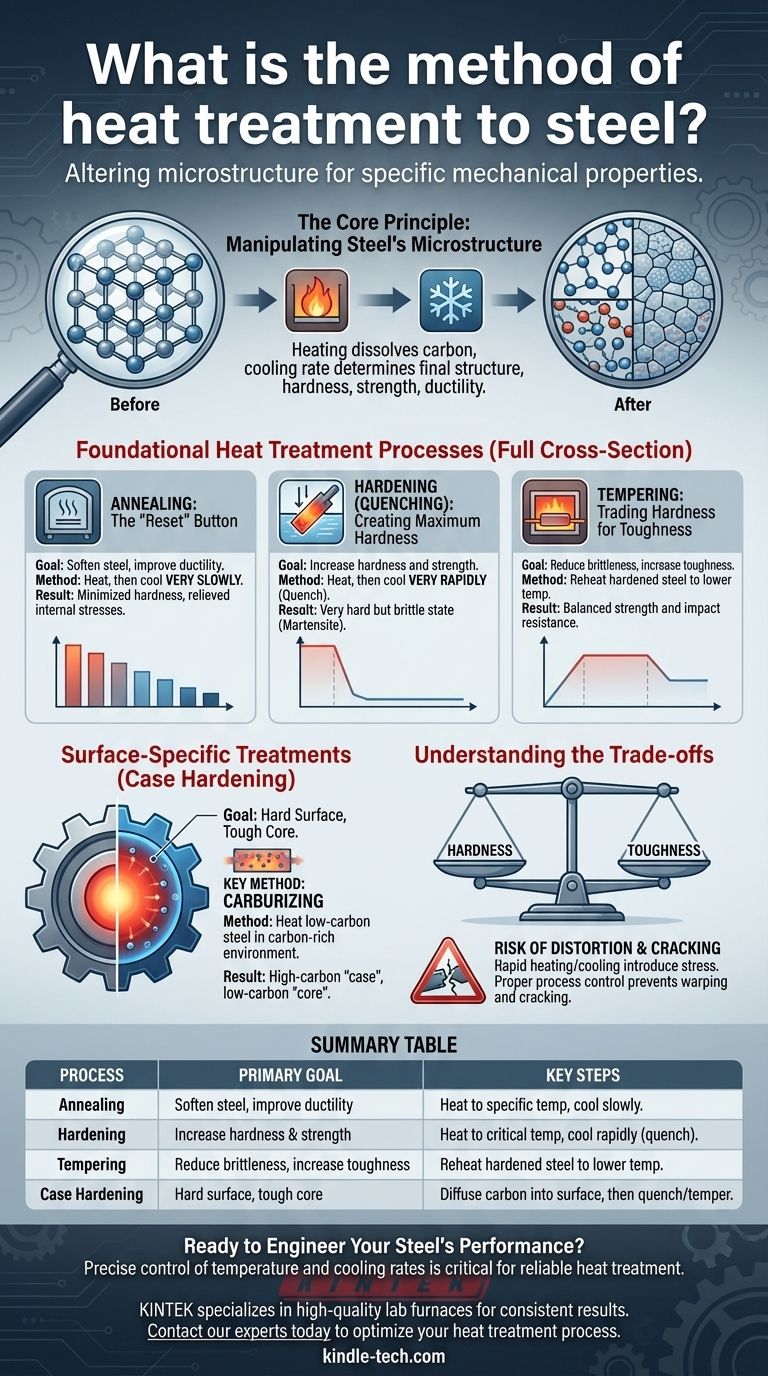

The Core Principle: Manipulating Steel's Microstructure

What Heat Treatment Actually Does

At a microscopic level, steel is a crystal structure of iron and carbon atoms. The way these crystals are arranged, known as the microstructure, dictates the steel's mechanical properties.

Heat treatment works by changing these arrangements. Heating the steel dissolves carbon into a specific crystal structure (austenite), and the speed at which it's cooled determines the final structure and, therefore, its hardness, strength, and ductility.

Foundational Heat Treatment Processes

These processes affect the entire cross-section of the steel part, altering its properties through and through.

Annealing: The "Reset" Button

The primary goal of annealing is to soften steel. This process makes the material more ductile and easier to machine or form.

It involves heating the steel to a specific temperature and then cooling it very slowly. This slow cooling allows the microstructure to form in a way that minimizes hardness and relieves internal stresses leftover from manufacturing.

Hardening (Quenching): Creating Maximum Hardness

Hardening is used to make steel significantly harder and stronger, increasing its resistance to wear.

The process involves heating the steel to a critical temperature until its structure transforms, then cooling it very rapidly. This rapid cooling, known as quenching, is often done in water, oil, or air and "traps" the steel in a very hard but brittle state called martensite.

Tempering: Trading Hardness for Toughness

A part that has been hardened is often too brittle for practical use. Tempering is the essential follow-up process to reduce that brittleness.

The hardened steel is reheated to a much lower temperature and held for a specific time. This process sacrifices some of the maximum hardness gained during quenching in exchange for a significant increase in toughness—the ability to absorb impact without fracturing.

Surface-Specific Treatments (Case Hardening)

Sometimes, you need a component with two different sets of properties: a wear-resistant surface and a tough, shock-absorbent interior. This is the goal of case hardening.

The Goal: A Hard Surface and a Tough Core

Think of gears or bearings. They need an extremely hard surface to resist constant friction and wear, but the core must remain tough and ductile to handle operational loads without cracking.

Case hardening creates this dual-property state by altering only the chemical composition of the steel's surface layer.

Key Method: Carburizing

Carburizing is a common case-hardening method. It involves heating a low-carbon steel in a carbon-rich environment.

Carbon atoms diffuse into the surface of the part, creating a high-carbon "case" or skin. The part is then quenched and tempered, resulting in a hard, wear-resistant outer layer while the low-carbon core remains tough and resilient.

Understanding the Trade-offs

Choosing a heat treatment method is never about maximizing a single property; it's about finding the right balance for the intended function.

The Hardness vs. Toughness Spectrum

This is the most fundamental trade-off in steel heat treatment. Increasing hardness almost always leads to a decrease in toughness (an increase in brittleness).

Tempering is the process used to navigate this spectrum, allowing engineers to dial in the precise balance required for a component to be both strong and durable.

The Risk of Distortion and Cracking

The rapid heating and, especially, the rapid cooling involved in quenching introduce massive internal stresses into the material.

If not managed correctly through proper process control, these stresses can cause the part to warp, distort, or even crack during or after treatment. This is a critical consideration in manufacturing.

Matching the Process to the Application

Your choice of heat treatment method should be driven entirely by the final performance requirements of the steel component.

- If your primary focus is machinability or stress relief: Annealing is the correct process to soften the material and make it workable.

- If your primary focus is extreme wear resistance on a surface: Case hardening techniques like carburizing will create a hard exterior while maintaining a tough core.

- If your primary focus is a balance of high strength and impact resistance: Hardening via quenching, followed by a precise tempering process, is the essential combination.

Ultimately, mastering heat treatment is about understanding that you are not just changing a material, but engineering its performance from the inside out.

Summary Table:

| Process | Primary Goal | Key Steps |

|---|---|---|

| Annealing | Soften steel, improve ductility | Heat to specific temperature, cool slowly |

| Hardening (Quenching) | Increase hardness and strength | Heat to critical temperature, cool rapidly (quench) |

| Tempering | Reduce brittleness, increase toughness | Reheat hardened steel to lower temperature |

| Case Hardening (e.g., Carburizing) | Hard surface, tough core | Diffuse carbon into surface, then quench and temper |

Ready to Engineer Your Steel's Performance?

Choosing the right heat treatment process is critical for achieving the perfect balance of hardness, strength, and toughness in your components. The precise control of temperature and cooling rates required for processes like quenching and tempering demands reliable equipment.

KINTEK specializes in high-quality lab furnaces and ovens designed for consistent and accurate heat treatment applications. Whether you are annealing, hardening, or carburizing, our equipment helps you achieve repeatable results and avoid issues like distortion.

Let us help you optimize your heat treatment process. Contact our experts today to discuss your specific laboratory needs and find the right solution for your application.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the necessity of using a high-temperature box furnace for the 300°C heat treatment? Curing & Adhesion Experts

- How is a high-temperature muffle furnace utilized in RTAC for catalyst preparation? Master Thermal Shock Engineering

- What is the function of a laboratory high-temperature furnace during LCFA calcination? Achieve Pure Perovskite Oxides

- What is a ceramic furnace? The Essential Tool for Transforming Clay into Durable Ceramics

- What is the meaning of muffle furnace? The Key to Pure, High-Temperature Processing

- What role does a high-temperature sintering furnace play in the crystalline phase formation of Li4Ti5O12?

- What is muffle furnace working principle and application? Achieve Contamination-Free High-Temperature Processing

- What is the power rating of a muffle furnace? Choose the Right Voltage & Power for Your Lab