In short, physical deposition is a process that uses mechanical or thermal energy to transfer a material from a source to a substrate, forming a thin film. It accomplishes this inside a vacuum chamber by turning the solid source material into a vapor, which then travels and condenses onto a cooler surface. Unlike chemical deposition, no chemical reactions are involved in creating the final film.

The core principle of physical deposition is a phase change, not a chemical change. The process physically liberates atoms from a solid source, transports them through a vacuum, and re-solidifies them onto a target surface to build a film atom by atom.

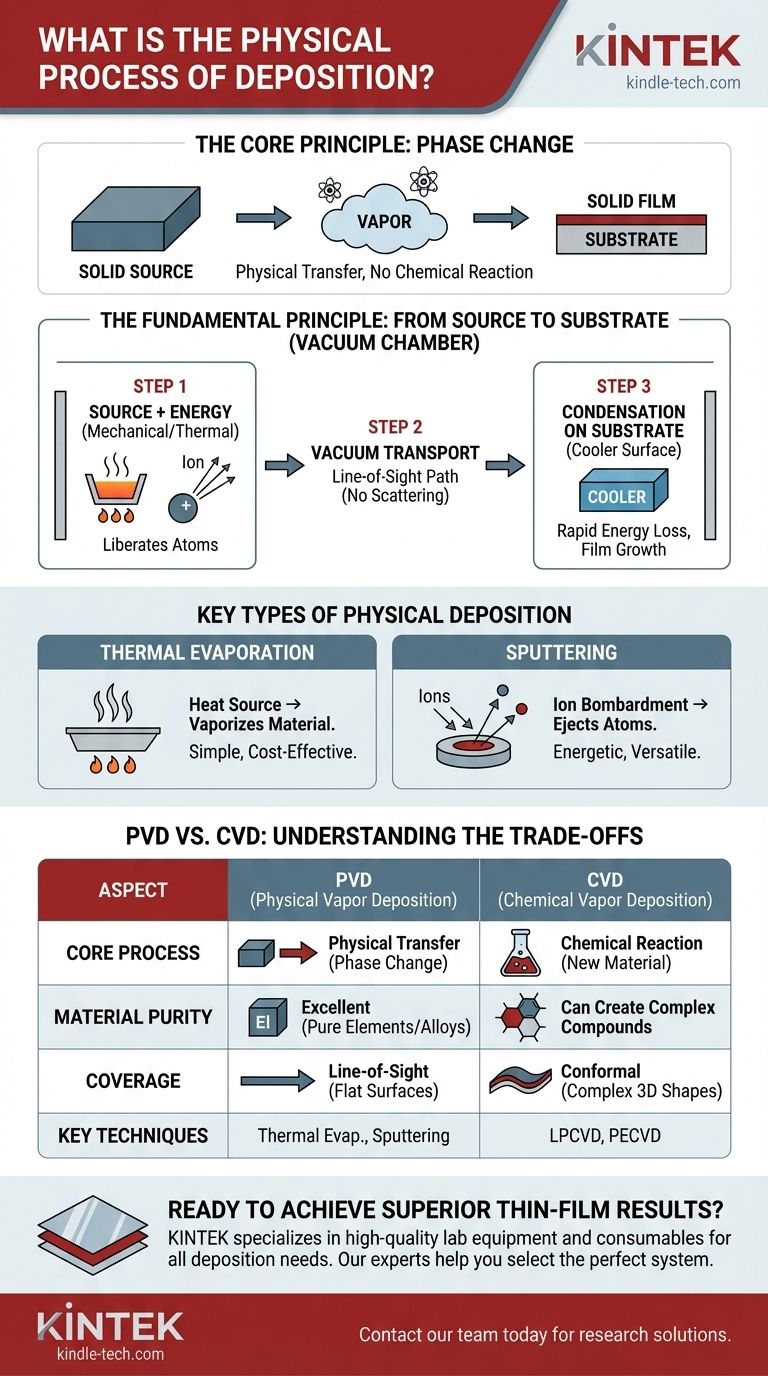

The Fundamental Principle: From Source to Substrate

Physical Vapor Deposition (PVD) is a family of processes built on a straightforward concept: moving matter from point A (the source) to point B (the substrate) without altering its chemical identity.

The Source Material and Energy

The process begins with a solid material, known as the "source" or "target," which is the substance you wish to deposit as a thin film.

Energy is then applied to this source to liberate individual atoms or molecules from its surface. This energy transfer is the "physical" mechanism at the heart of the process.

The Importance of a Vacuum

All PVD processes occur inside a vacuum chamber. This high-vacuum environment is critical because it removes air and other gas particles that would otherwise collide with and scatter the liberated source atoms.

A vacuum ensures the atoms can travel in a straight line from the source directly to the substrate, a concept often called line-of-sight deposition.

Condensation on the Substrate

When the stream of vaporized atoms strikes the target object, known as the "substrate," it encounters a much cooler surface.

This temperature difference causes the atoms to rapidly lose energy and condense back into a solid state, gradually building up a thin, uniform film on the substrate's surface.

Key Types of Physical Deposition

While the principle is the same, the method of applying energy to the source defines the specific type of PVD process. The two most common methods are thermal evaporation and sputtering.

Thermal Evaporation

This is one of the oldest and simplest PVD techniques. The source material is heated in the vacuum chamber until its temperature is high enough to cause it to evaporate, turning it directly into a vapor.

This vapor then travels through the chamber and condenses on the substrate, just like steam condensing on a cold mirror.

Sputtering

Sputtering uses electromechanical force instead of heat. In this process, a solid target is bombarded with high-energy ions (typically from an inert gas like Argon) that have been accelerated in a plasma.

These energetic ions act like atomic-scale sandblasters, physically knocking atoms off the target material. These "sputtered" atoms are ejected into the chamber and subsequently deposit onto the substrate.

Understanding the Trade-offs: Physical vs. Chemical Deposition

The most common alternative to PVD is Chemical Vapor Deposition (CVD). Understanding their differences is key to choosing the right tool for a job.

The Core Distinction: Phase Change vs. Chemical Reaction

The fundamental difference is simple. PVD physically moves an existing material. The film on your substrate is chemically identical to the source material it came from.

CVD chemically creates a new material. It introduces reactive precursor gases into a chamber that then react on the substrate's surface to form a solid film. The resulting film is a product of that chemical reaction.

Purity and Simplicity

Because PVD is a physical transfer process, it is an excellent method for depositing extremely pure elemental materials and simple alloys. There are no complex precursors or chemical byproducts to manage.

Coverage and Conformality

PVD is primarily a line-of-sight process. This makes it excellent for coating flat surfaces but can make it difficult to uniformly coat complex, three-dimensional shapes with undercuts or trenches.

CVD gases, by contrast, can flow around objects and react on all exposed surfaces, generally providing better conformal coverage over intricate geometries.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning the process capabilities with your technical and economic goals.

- If your primary focus is depositing a pure elemental material or simple alloy: PVD is often the most direct and effective choice due to its physical nature.

- If your primary focus is creating a complex compound film (like silicon nitride): CVD is likely necessary, as it builds the material through chemical reactions on the surface.

- If your primary focus is coating an intricate 3D object uniformly: CVD's ability to provide conformal coverage often makes it the superior option.

- If your primary focus is a simple, cost-effective metallic film: Thermal evaporation, a PVD method, is a mature and highly economical technology.

Ultimately, understanding whether you need to physically move a material or chemically create it is the key to mastering deposition technology.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Process | Physical transfer via phase change | Chemical reaction on the surface |

| Material Purity | Excellent for pure elements/simple alloys | Can create complex compounds |

| Coverage | Line-of-sight (good for flat surfaces) | Conformal (good for complex 3D shapes) |

| Key Techniques | Thermal Evaporation, Sputtering | LPCVD, PECVD |

Ready to achieve superior thin-film results with the right deposition technology?

KINTEK specializes in providing high-quality lab equipment and consumables for all your deposition needs. Whether you are exploring PVD for pure metal coatings or require solutions for complex CVD applications, our experts can help you select the perfect system for your laboratory's specific challenges.

Contact our team today to discuss your project and discover how KINTEK's solutions can enhance your research and development.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing