In short, the potential of carbon nanotubes (CNTs) lies in their extraordinary electrical, thermal, and mechanical properties at the nanoscale. They are primarily used as a powerful additive to dramatically enhance the performance of other materials, from the batteries in our devices to next-generation composites and electronics.

Carbon nanotubes are best understood not as a standalone miracle material, but as a "master enhancer." Their true potential is realized when they are integrated into other materials to confer new properties, like conductivity and strength, that were previously unachievable.

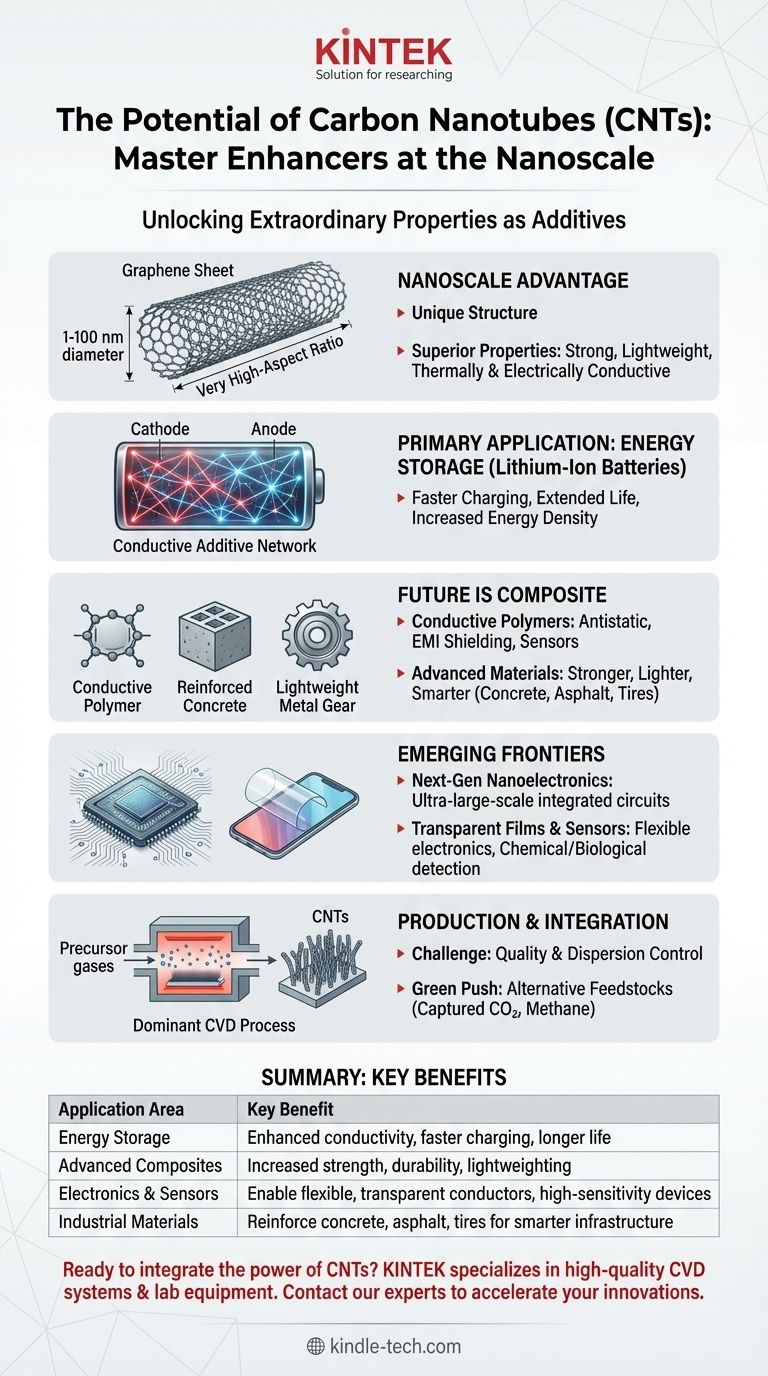

Why Carbon Nanotubes Matter: The Nanoscale Advantage

The Unique Structure of CNTs

Carbon nanotubes are cylindrical molecules made of rolled-up sheets of single-layer carbon atoms. They are a nanomaterial, meaning their size ranges from just 1 to 100 nanometers.

This structure gives them a very high-aspect ratio (length to diameter), which is critical for creating conductive and reinforcing networks within other materials.

Unlocking Superior Properties

At this tiny scale, CNTs exhibit a unique combination of properties. They are exceptionally strong, lightweight, and possess remarkable thermal and electrical conductivity.

It is this combination of traits that makes them a target for innovation across numerous industries.

Primary Application: Enhancing Energy Storage

The Critical Role in Lithium-Ion Batteries

The most significant commercial application for CNTs today is as a conductive additive in the electrodes of lithium-ion batteries.

By forming a highly conductive network within the cathode and anode, CNTs improve charging speeds, extend battery life, and increase overall energy density. This is a mature application with established supply chains.

The Future is Composite: Building Stronger, Smarter Materials

Conductive Polymers and Reinforced Plastics

When mixed with polymers, CNTs can make plastics electrically conductive, opening up applications in antistatic materials, EMI shielding, and sensors. They also significantly increase the strength and durability of fiber-reinforced composites.

Advanced Construction and Industrial Materials

Research is actively exploring the use of CNTs to reinforce concrete and asphalt, potentially increasing longevity and adding smart-sensing capabilities. They are also being developed for stronger, lighter metal composites and more durable, efficient tires.

Emerging Frontiers in Technology

Next-Generation Nanoelectronics

Specialized CNTs can be precisely deposited using methods like plasma-enhanced chemical vapor deposition (PECVD). This enables their integration into traditional microelectronics, paving the way for ultra-large-scale integrated circuits and advanced field-emission displays.

Transparent Films and Advanced Sensors

CNTs can be used to create transparent conductive films, a potential alternative to conventional materials in touch screens and flexible electronics. Their high surface area also makes them extremely effective in chemical and biological sensors.

Understanding the Trade-offs: Production and Integration

The Dominance of Chemical Vapor Deposition (CVD)

While older methods exist, Chemical Vapor Deposition (CVD) is the dominant commercial process for producing CNTs. This process offers scalability but requires careful control.

The Challenge of Quality and Control

The final properties of CNTs are highly sensitive to manufacturing parameters like temperature, carbon source, and residence time. Ensuring consistent quality and achieving proper dispersion into a host material remain key technical challenges.

The Push for Greener Production

To address sustainability, emerging methods are being developed to produce CNTs from alternative feedstocks. These include using captured carbon dioxide via electrolysis or breaking down methane, turning waste streams into high-value materials.

How to View the Potential of CNTs

Ultimately, evaluating the potential of carbon nanotubes depends entirely on your goal.

- If your primary focus is immediate commercial application: The most proven and scalable use is as a conductive additive to improve performance in lithium-ion batteries.

- If your primary focus is materials science and engineering: Explore their use in creating a new generation of advanced polymer, concrete, and metal composites with enhanced properties.

- If your primary focus is future technology and R&D: Investigate their game-changing potential in nanoelectronics, transparent conductive films, and novel green production methods.

The potential of carbon nanotubes is defined not by what they are, but by what they empower other materials to become.

Summary Table:

| Application Area | Key Benefit of CNTs |

|---|---|

| Energy Storage (Batteries) | Enhanced conductivity, faster charging, longer life |

| Advanced Composites | Increased strength, durability, and lightweighting |

| Electronics & Sensors | Enable flexible, transparent conductors and high-sensitivity devices |

| Industrial Materials | Reinforce concrete, asphalt, and tires for smarter infrastructure |

Ready to integrate the power of carbon nanotubes into your research or product development?

KINTEK specializes in providing high-quality lab equipment and consumables, including advanced chemical vapor deposition (CVD) systems essential for CNT research and production. Our expertise supports laboratories and industries in developing next-generation materials, from stronger composites to more efficient batteries.

Contact our experts today via our Contact Form to discuss how our solutions can accelerate your nanotechnology innovations.

Visual Guide

Related Products

- Laboratory CVD Boron Doped Diamond Materials

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Warm Isostatic Press for Solid State Battery Research

- Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

People Also Ask

- What is an example of sputtering? Creating Anti-Reflective Coatings and Advanced Materials

- What materials do you need to make a diamond? It's Simpler Than You Think

- Is CVD or HPHT better? Your Guide to Choosing the Right Lab-Grown Diamond

- Can silicon be sputtered? A Guide to RF & DC Methods for Thin Film Deposition

- What is the effect of deposition rate on thin film? Control Microstructure for Better Performance

- What are the applications of nanotubes in industry? Enhancing Strength, Conductivity, and Efficiency

- What are the applications of graphene properties? Unlocking Next-Generation Electronics & Materials

- Which of the following is an advantage of using carbon nanotubes? Unlock Unmatched Material Performance