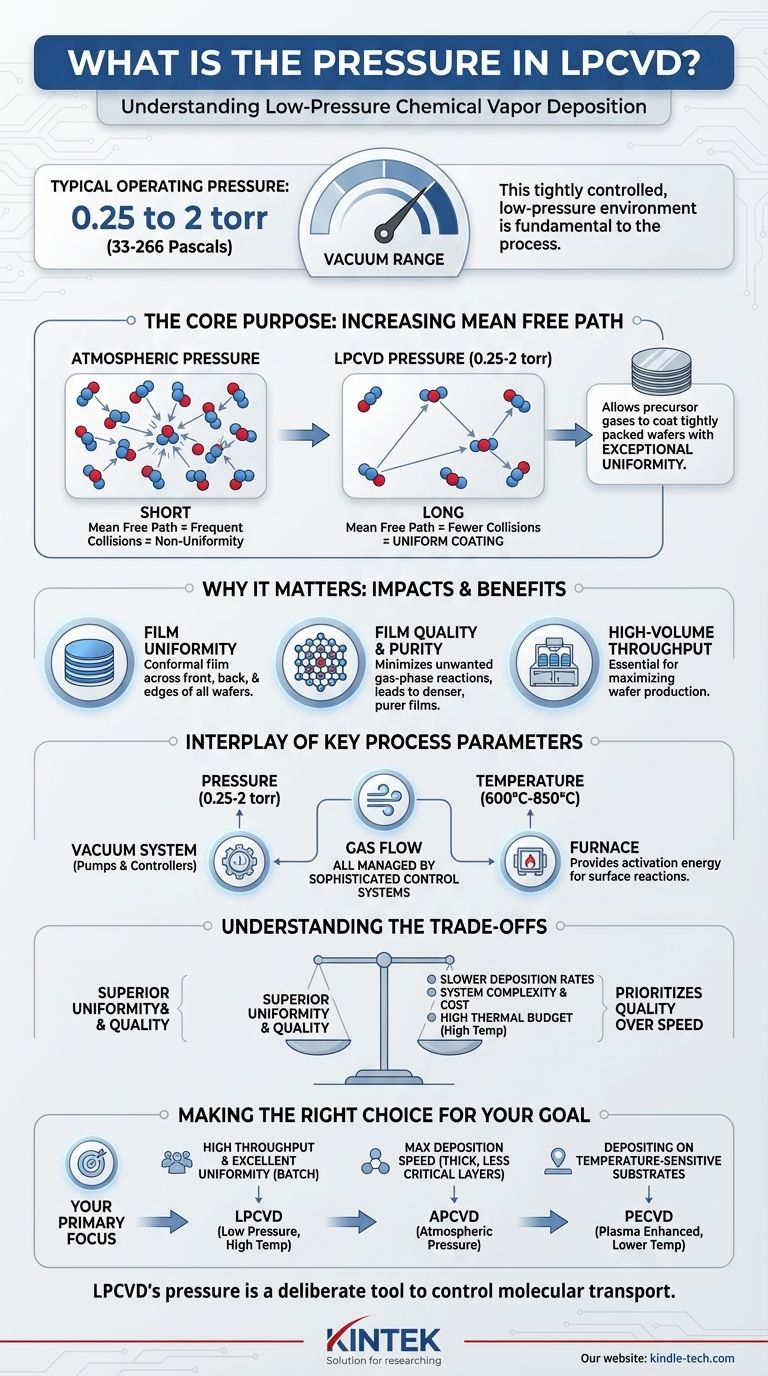

The typical operating pressure for Low-Pressure Chemical Vapor Deposition (LPCVD) falls within a tightly controlled vacuum range of 0.25 to 2 torr (approximately 33 to 266 Pascals). This low-pressure environment is fundamental to the process, differentiating it from atmospheric pressure methods and enabling its primary advantages in semiconductor manufacturing.

The core purpose of using low pressure in LPCVD is not arbitrary; it is a strategic choice to increase the "mean free path" of gas molecules. This allows precursor gases to coat tightly packed wafers with exceptional uniformity, making it a cornerstone for high-volume, high-quality film deposition.

Why This Specific Pressure Range Matters

The decision to operate in a vacuum is central to how LPCVD achieves its results. The pressure directly dictates the behavior of the reactive gases within the chamber, influencing everything from film quality to manufacturing throughput.

The Critical Role of Mean Free Path

The mean free path is the average distance a gas molecule travels before colliding with another. This concept is the key to understanding LPCVD.

At atmospheric pressure, the mean free path is extremely short, meaning molecules collide constantly. This leads to gas-phase reactions and non-uniform deposition.

By reducing the pressure to the 0.25-2 torr range, we drastically decrease the number of gas molecules in the chamber. This extends the mean free path, allowing molecules to travel further without interference before reaching a surface.

The Impact on Film Uniformity

A long mean free path is what enables the exceptional film uniformity of LPCVD. Precursor gases can travel deep into the spaces between wafers that are stacked vertically and close together.

This ensures all surfaces—front, back, and edges—receive a similar concentration of reactants, resulting in a highly conformal and uniform film across every wafer in the batch. This capability is essential for maximizing wafer throughput.

Enhancing Film Quality and Purity

Low pressure minimizes unwanted gas-phase reactions. Instead of reacting in the space between wafers, the chemical reaction is designed to occur primarily on the hot wafer surface.

This surface-reaction-limited process leads to a denser, more stoichiometric, and higher-purity film with better electrical and mechanical properties compared to films grown in high-pressure environments.

The Interplay of Key Process Parameters

Pressure does not work in isolation. It is part of a carefully balanced system with temperature and gas flow, all managed by sophisticated control systems.

The Function of Vacuum Systems

Achieving and maintaining this low pressure requires a robust vacuum system. Vacuum pumps are used to evacuate the chamber, while precise pressure control systems modulate gas flow and pumping speed to keep the pressure constant throughout the deposition process.

The Necessity of High Temperature

The reference temperature range of 600°C to 850°C is directly linked to the low-pressure environment. The reduction in pressure also reduces the thermal energy transfer within the chamber.

Therefore, high temperatures are required to provide the necessary activation energy for the chemical reaction to proceed efficiently on the wafer surface.

Understanding the Trade-offs

While highly effective, the low-pressure approach of LPCVD comes with inherent compromises that make it suitable for some applications but not others.

Slower Deposition Rates

A primary trade-off of reducing reactant concentration (i.e., lowering pressure) is a slower deposition rate compared to Atmospheric Pressure CVD (APCVD). The process prioritizes quality and uniformity over raw speed.

System Complexity and Cost

Operating under a vacuum introduces significant equipment complexity. The need for high-performance vacuum pumps, seals, and advanced control systems increases the capital and maintenance costs of an LPCVD system.

Thermal Budget Limitations

The high temperatures required for LPCVD can be a limitation. This high "thermal budget" can damage previously fabricated structures on a wafer or be incompatible with temperature-sensitive substrates.

Making the Right Choice for Your Goal

The operating pressure is a defining feature of a deposition technique. Your specific goal determines whether the low-pressure environment of LPCVD is the correct choice.

- If your primary focus is high throughput and excellent film uniformity across many wafers: LPCVD is the superior choice due to its ability to process densely packed vertical batches.

- If your primary focus is maximum deposition speed for thick, less-critical layers: An atmospheric pressure process (APCVD) may be more efficient, though at the cost of film quality and conformity.

- If your primary focus is depositing films on temperature-sensitive substrates: You should consider Plasma-Enhanced CVD (PECVD), which uses plasma energy instead of high heat to drive the reaction at lower temperatures.

Ultimately, understanding that LPCVD's pressure is a deliberate tool to control molecular transport is the key to leveraging the process effectively.

Summary Table:

| Parameter | Typical LPCVD Range | Purpose & Impact |

|---|---|---|

| Operating Pressure | 0.25 - 2 torr | Increases mean free path for exceptional film uniformity and conformity. |

| Temperature | 600°C - 850°C | Provides activation energy for surface reactions in the low-pressure environment. |

| Primary Advantage | Superior step coverage & batch uniformity | Ideal for high-volume semiconductor manufacturing. |

| Key Trade-off | Slower deposition rate | Sacrifices speed for ultimate film quality and conformity. |

Need precise, high-quality film deposition for your lab? The controlled pressure environment of LPCVD is critical for success. KINTEK specializes in high-performance lab equipment, including vacuum and thermal systems essential for processes like LPCVD. Let our experts help you select the right equipment to achieve superior uniformity and throughput in your semiconductor or materials research.

Contact our team today to discuss your specific laboratory needs and discover how KINTEK's solutions can enhance your research and development.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the chemical solution deposition method also known as? Discover the Sol-Gel Process for Thin Films

- What is chemical vapour deposition of graphene synthesis? A Guide to Scalable, High-Quality Graphene Production

- What are the steps of chemical vapor deposition? Build Superior Thin Films Atom by Atom

- What are the applications of graphene nanocomposites? From Aerospace to Biomedicine

- What is the general process of growing diamonds using the CVD method? Master Precision Lab-Grown Diamond Technology

- Which gas is used in CVD process? Unlocking the Precise Gas Mixtures for Superior Thin Films

- Why is it preferred to use carbon nanotubes as catalysts in chemical industries? Maximize Catalytic Performance & Efficiency

- What is the precursor in CVD graphene? The Key to High-Quality, Large-Area Films