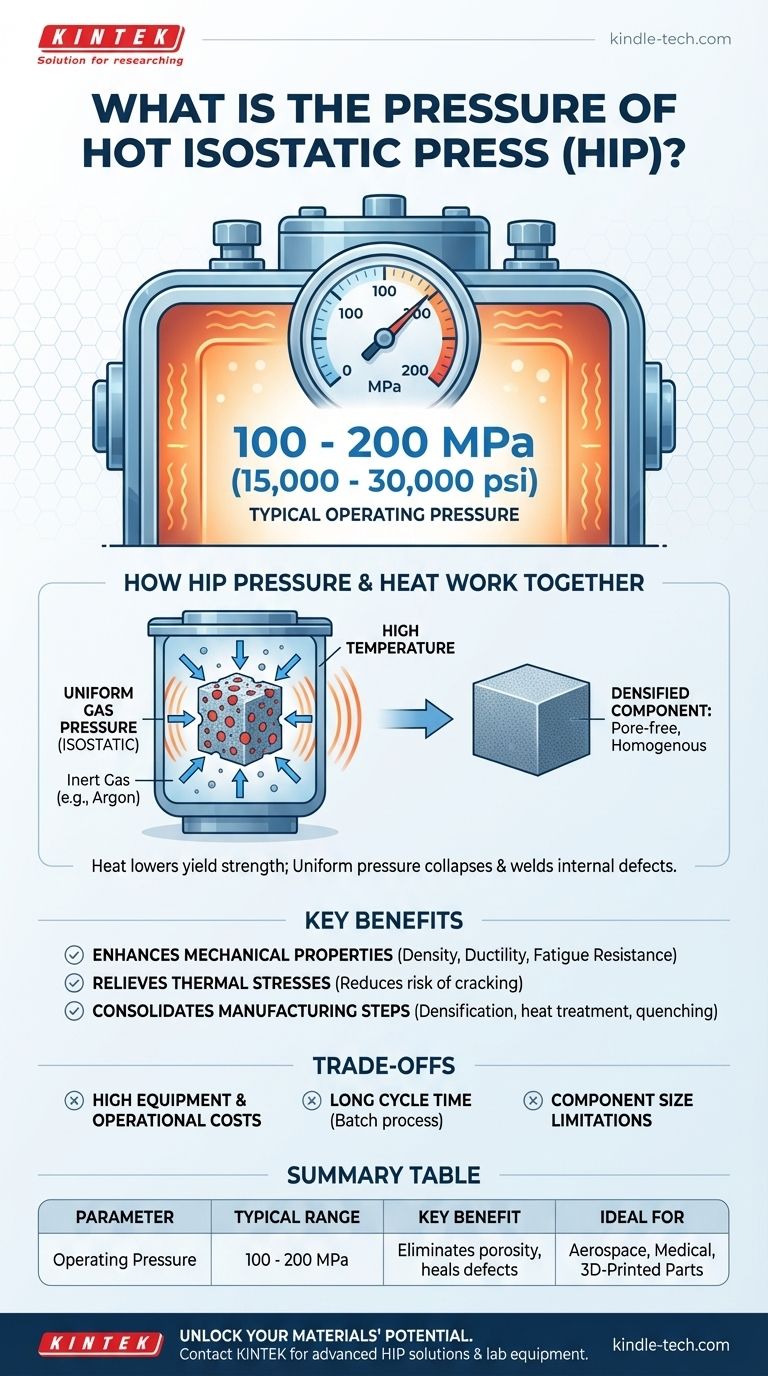

Hot isostatic pressing typically operates at pressures ranging from 100 to 200 MPa (approximately 15,000 to 30,000 psi), although the exact value depends on the material and the desired outcome. This immense pressure is applied uniformly in conjunction with elevated temperatures to densify materials and heal internal defects.

The core purpose of pressure in Hot Isostatic Pressing (HIP) is not merely to compact a part, but to create a force so uniform and powerful that it physically closes internal voids and fuses materials on a microscopic level, resulting in a fully dense, high-performance component.

How Pressure and Heat Work Together in HIP

Hot isostatic pressing is a sophisticated manufacturing process that subjects components to both high temperature and high, uniform gas pressure in a specialized vessel. This combination achieves results that neither heat nor pressure could accomplish alone.

The Principle of Uniform ("Isostatic") Pressure

The term isostatic is key. It means the pressure is applied equally from all directions.

This is achieved by using an inert gas, typically argon, as the pressure medium. This ensures that even components with complex geometries are compressed evenly, without the distortion that could occur in a conventional mechanical press.

The Critical Role of Temperature

While the pressure is high, it's the addition of heat that makes the process so effective.

The elevated temperature lowers the material's yield strength, making it more malleable. This allows the gas pressure to effectively collapse and weld shut internal pores, voids, or micro-cracks within the material.

The Goal: A Perfect, Uniform Microstructure

The combination of uniform pressure and high temperature eliminates porosity from processes like casting or 3D printing.

It also heals issues like poor layer adhesion in additively manufactured parts, creating a homogenous and uniform internal structure that dramatically improves the part's integrity.

The Key Benefits of the HIP Process

Applying this controlled pressure and temperature yields significant, measurable improvements in a material's final properties.

Enhancing Mechanical Properties

By eliminating internal defects, HIP drastically improves part density, ductility, and resistance to fatigue. This is critical for components that will be subjected to high stress or cyclical loading.

Relieving Thermal Stresses

The process is highly effective at relieving internal stresses that build up in parts during casting, sintering, or additive manufacturing. This reduces the risk of future cracking or failure.

Consolidating Manufacturing Steps

Modern HIP systems can integrate multiple processes into a single cycle. A part can undergo densification, heat treatment, quenching, and aging within the same machine, significantly reducing overall production time and handling.

Understanding the Trade-offs

While powerful, HIP is a specialized process with specific considerations. It is not the right solution for every application.

Equipment and Operational Costs

The machinery required to safely contain extreme pressures and temperatures is complex and expensive. The use of high-purity argon gas and significant energy consumption also adds to the operational cost.

Process Cycle Time

A typical HIP cycle can take several hours to complete. This includes the time needed to heat the vessel, hold at temperature and pressure, and cool down. It is a batch process, making it less suitable for high-volume, low-cost production.

Component Size Limitations

Parts must fit inside the HIP pressure vessel. While modern systems can be quite large—with diameters up to 80 inches (2000 mm)—this still places a physical constraint on the size of the components that can be treated.

Making the Right Choice for Your Goal

Deciding to use HIP depends entirely on the performance requirements of your final component.

- If your primary focus is maximum reliability and fatigue life: HIP is the definitive process for healing defects in critical components used in aerospace, medical, or energy applications.

- If your primary focus is improving 3D-printed metal parts: HIP is an essential post-processing step to achieve the density and strength of a traditionally wrought material.

- If your primary focus is manufacturing efficiency: HIP can provide a significant advantage by combining multiple heat treatment and stress relief steps into a single, controlled cycle.

Ultimately, hot isostatic pressing is a powerful finishing tool for achieving material properties and performance levels that are simply unattainable by other means.

Summary Table:

| Parameter | Typical Range |

|---|---|

| Operating Pressure | 100 - 200 MPa (15,000 - 30,000 psi) |

| Key Benefit | Eliminates porosity, heals defects, improves fatigue life |

| Ideal For | Aerospace, medical implants, high-performance 3D-printed parts |

Ready to unlock the full potential of your materials?

KINTEK specializes in advanced hot isostatic pressing solutions for laboratories and manufacturers. Our HIP systems are designed to deliver the uniform pressure and precise temperature control required to achieve full density, superior mechanical properties, and maximum reliability for your most critical components.

Whether you are working with castings, 3D-printed metals, or ceramics, our expertise can help you eliminate internal defects and enhance performance.

Contact KINTEK today to discuss how our lab equipment and consumables can meet your specific HIP needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the process of SPS? A Complete Guide to Spark Plasma Sintering

- How does 1.20 GPa pressure in vacuum hot pressing affect WC/Cu-Zr-Ti composites? Engineering Nanocrystalline Structures

- Why is a hot pressing sintering machine superior for nanocopper? Unlock Elite Material Density and Performance

- What is the cost of a spark plasma sintering system? A Detailed Breakdown of SPS Investment

- What are the advantages of a vacuum hot press furnace for W-50%Cu? Achieve 99.6% Density at Lower Temperatures

- Why is a precise pressure control system in a vacuum hot pressing furnace essential for Al/B4C composite manufacturing?

- What are the advantages of using a vacuum hot press furnace for sintering CNT/Cu composites? Superior Density & Bonding

- Why is 1 GPa critical for nano-tungsten during vacuum hot pressing? Achieve High Density at Low Temperatures