In Hot Isostatic Pressing (HIP), the process typically operates under extremely high pressures, generally ranging from 100 to 200 megapascals (MPa), which is equivalent to approximately 15,000 to 30,000 pounds per square inch (psi). This immense, uniform pressure is applied via a high-temperature inert gas to consolidate materials and eliminate internal defects.

The specific pressure value in Hot Isostatic Pressing is less important than its function. The goal is to apply pressure that is high enough and uniform enough to physically close all internal voids, creating a fully dense part with superior mechanical properties.

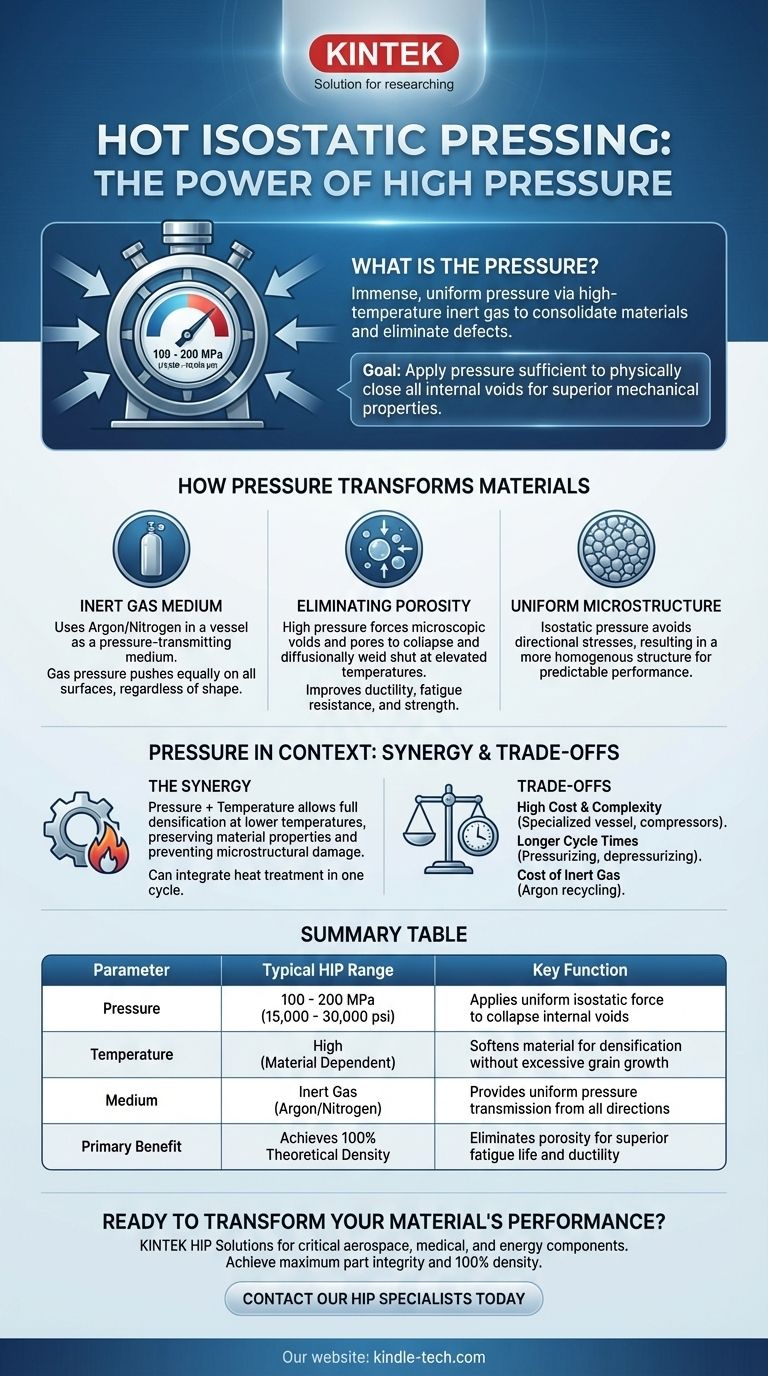

How High Pressure Transforms Materials

The primary function of pressure in the HIP process is to subject a component to a force that is uniform from every direction. This isostatic pressure, combined with elevated temperature, fundamentally alters the material's internal structure for the better.

The Role of Inert Gas

Unlike mechanical pressing, HIP does not use a physical die to apply force. Instead, the component is placed in a high-pressure vessel that is then filled with an inert gas, such as argon or nitrogen.

This gas is heated and compressed, acting as the pressure-transmitting medium. Because gas pressure is inherently uniform, it pushes on every surface of the component with equal force, regardless of the part's geometric complexity.

Eliminating Porosity at a Microscopic Level

The core benefit of HIP is the complete removal of internal porosity. At elevated temperatures, the material becomes soft enough (plastic) for the high external gas pressure to cause microscopic voids, pores, and cracks to collapse and diffusionally weld shut.

This process transforms a cast, sintered, or 3D-printed part with potential internal flaws into a fully dense, solid object. The result is a significant improvement in ductility, fatigue resistance, and overall strength.

Creating a Uniform Microstructure

Because the pressure is isostatic (uniform), it consolidates the material without introducing the directional stresses that are common in other forming processes like forging or extrusion.

This leads to a more homogenous and uniform microstructure throughout the part. This uniformity is critical for applications where performance predictability is non-negotiable.

Pressure in Context: More Than Just a Number

The pressure in a HIP cycle does not work in isolation. It is part of a precisely controlled thermal-mechanical process where it interacts directly with temperature and time.

The Synergy of Pressure and Temperature

HIP allows for full densification at temperatures significantly lower than those required for conventional sintering or hot pressing. The high pressure provides the driving force for consolidation, reducing the need for extreme heat.

This is a critical advantage, as it allows materials to be processed without the risk of grain growth, phase changes, or other microstructural damage that can occur at higher temperatures, thereby preserving or enhancing material properties.

Combining Manufacturing Steps

Modern HIP systems can integrate heat treatment, quenching, and aging processes into a single cycle. By precisely controlling the pressure, temperature, and cooling rates, it's possible to consolidate a part and achieve its final required heat-treated properties simultaneously. This dramatically reduces overall production time and handling.

Understanding the Trade-offs

While incredibly effective, the high pressures used in HIP introduce specific technical and economic considerations.

Equipment Cost and Complexity

Generating and containing gas pressures up to 30,000 psi at high temperatures requires specialized and robust equipment. The high-pressure vessel is a critical, expensive component, and the associated compressors, pumps, and control systems add to the complexity and cost.

Cycle Time and Throughput

Safely pressurizing and depressurizing a large vessel takes time. The overall cycle time for a HIP run can be several hours, which can impact production throughput compared to faster, lower-pressure methods.

The Cost of the Pressure Medium

As noted, the process relies on expensive inert gases like argon. While these gases are recovered and recycled, the initial investment and the infrastructure to handle them contribute to the operational cost.

Making the Right Choice for Your Goal

The decision to use HIP is a function of your final component requirements. The pressure is the tool used to achieve a specific end.

- If your primary focus is maximum part integrity: HIP is the definitive solution for eliminating internal defects in critical components, such as aerospace turbine blades or medical implants.

- If your primary focus is improving additively manufactured parts: HIP is essential for healing porosity and improving layer-to-layer bonding, transforming a 3D-printed part into a fully dense, high-performance component.

- If your primary focus is cost-effective production: The high cost of HIP must be justified by the performance gains; for less critical applications, other densification methods may be sufficient.

Ultimately, the high pressure of Hot Isostatic Pressing is the key that unlocks a material's full theoretical density and performance potential.

Summary Table:

| Parameter | Typical HIP Range | Key Function |

|---|---|---|

| Pressure | 100 - 200 MPa (15,000 - 30,000 psi) | Applies uniform isostatic force to collapse internal voids |

| Temperature | High (Material Dependent) | Softens material for densification without excessive grain growth |

| Medium | Inert Gas (Argon/Nitrogen) | Provides uniform pressure transmission from all directions |

| Primary Benefit | Achieves 100% Theoretical Density | Eliminates porosity for superior fatigue life and ductility |

Ready to transform your material's performance?

Hot Isostatic Pressing is the definitive solution for achieving maximum part integrity in critical applications. If you work with castings, sintered materials, or additive manufacturing (3D printing) and require components with superior fatigue resistance, ductility, and 100% density, KINTEK's HIP expertise is your answer.

We specialize in providing advanced lab equipment and consumables to meet the demanding needs of the aerospace, medical, and energy sectors. Let us help you unlock the full potential of your materials.

Contact our HIP specialists today to discuss how our solutions can enhance your laboratory's capabilities and product quality.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Double Plate Heating Press Mold for Lab

- Touchscreen Automatic Vacuum Heat Press

People Also Ask

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What advantages does a warm isostatic press offer over a traditional uniaxial press for Li6PS5Cl electrolyte sheets?

- Why is a Hot Isostatic Press (HIP) required for Eu:Y2O3 samples? Unlock Optical-Grade Ceramic Transparency

- Why is Hot Isostatic Pressing (HIP) Required for Additive Inconel 718? Achieve 100% Theoretical Density

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density

- What is the application of HIP? Eliminate Porosity for Superior Material Performance

- What is the temperature and pressure for hot isostatic pressing? Achieve 100% Dense, High-Performance Materials