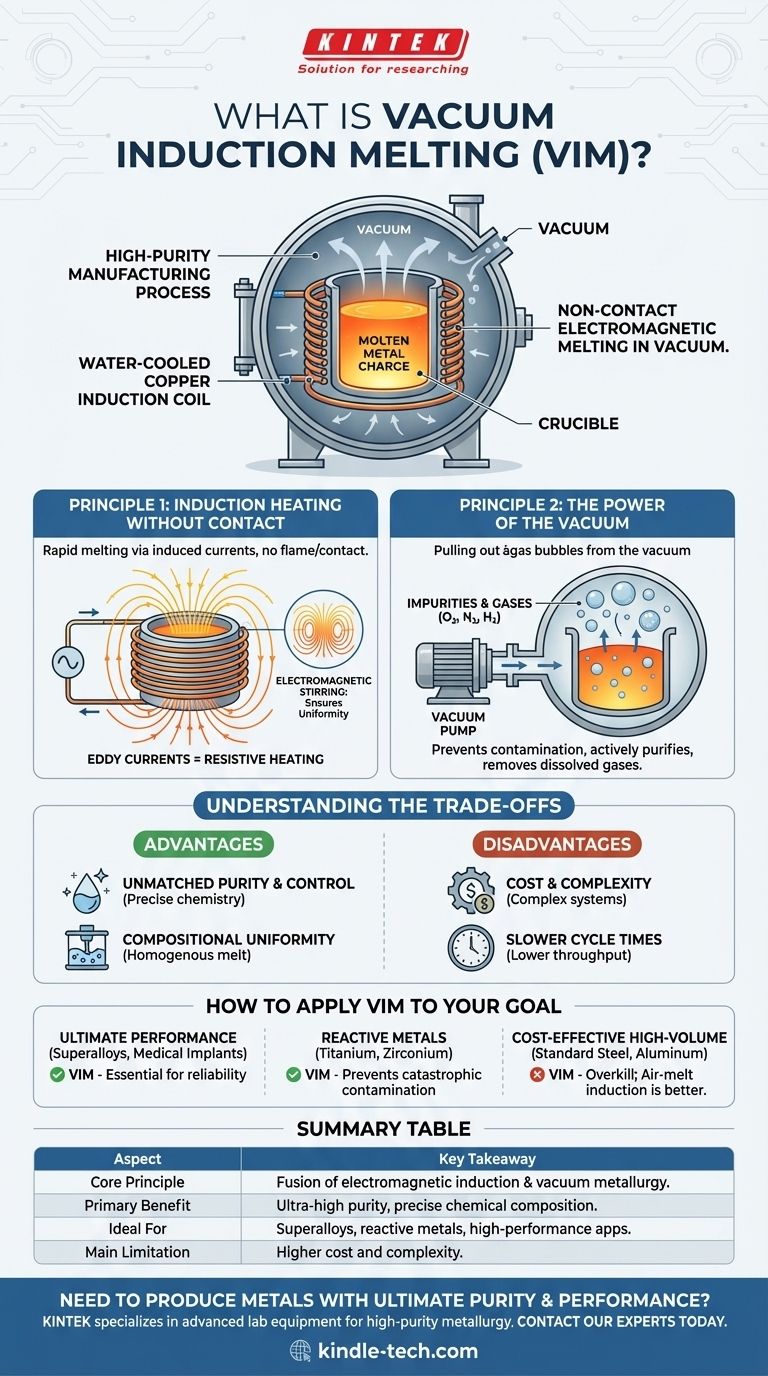

At its core, vacuum induction melting is a high-purity manufacturing process that uses non-contact electromagnetic forces to melt metal inside a vacuum-sealed chamber. This dual-action method first uses an induced electrical current to generate intense heat for melting, while the vacuum environment simultaneously removes harmful gases and prevents airborne contamination, resulting in exceptionally clean and uniform metals.

The critical takeaway is that vacuum induction melting (VIM) is not just a method for melting metal. It is a highly controlled refining process designed to produce materials with superior purity and precise chemical compositions that are impossible to achieve in an open-air environment.

Deconstructing the VIM Process: Two Core Principles

To truly understand VIM, you must see it as the fusion of two distinct physical principles working in concert: electromagnetic induction and vacuum metallurgy. One provides the clean heat source, and the other provides the pristine environment.

Principle 1: Induction Heating Without Contact

The "induction" in VIM is a method of generating heat directly within the metal itself. An alternating current (AC) is passed through a water-cooled copper coil that surrounds a crucible containing the solid metal charge.

This coil acts as the primary winding of a transformer. The metal inside the crucible effectively becomes a single-turn secondary winding.

The rapidly changing magnetic field generated by the coil induces powerful circulating electrical currents, known as eddy currents, within the metal. The metal's natural electrical resistance causes this current to generate intense heat (resistive heating), quickly raising the temperature to its melting point without any flame or external heating element touching the material.

The Added Benefit: Electromagnetic Stirring

The same electromagnetic forces that generate heat also exert a powerful force on the molten metal. This creates a natural, continuous stirring action within the crucible.

This electromagnetic stirring is a significant advantage. It ensures that any added alloying elements are mixed thoroughly and that the final temperature and composition of the melt are perfectly uniform, eliminating inconsistencies in the final product.

Principle 2: The Power of the Vacuum

The "vacuum" is the active refining agent in the process. The entire furnace—coil, crucible, and metal—is housed within an airtight chamber from which air is removed.

This accomplishes two critical goals. First, it prevents contamination. Many advanced alloys and reactive metals like titanium will readily react with oxygen and nitrogen in the air, forming undesirable oxides and nitrides that compromise material properties. The vacuum eliminates this possibility.

Second, it actively purifies the metal. As the metal melts, the low-pressure environment essentially pulls dissolved gases, such as hydrogen and oxygen, out of the liquid. This degassing step is crucial for creating metals with high strength, ductility, and fatigue resistance.

Understanding the Trade-offs of VIM

While VIM produces materials of exceptional quality, it is not the solution for every application. Understanding its advantages and disadvantages is key to deploying it correctly.

Advantage: Unmatched Purity and Control

The primary reason to use VIM is to achieve the lowest possible levels of gas impurities (oxygen, nitrogen, hydrogen) and volatile tramp elements. This results in ultra-clean metals with precisely controlled chemistry, essential for high-performance applications.

Advantage: Compositional Uniformity

The inherent electromagnetic stirring guarantees a homogenous melt from top to bottom. This is critical for complex alloys where even minor variations in composition can lead to defects or inconsistent mechanical properties.

Disadvantage: Cost and Complexity

VIM furnaces are complex systems that involve high-power electrical supplies, robust vacuum pumps, and sophisticated controls. This makes them significantly more expensive to build, operate, and maintain than standard air-melt induction or arc furnaces.

Disadvantage: Slower Cycle Times

The need to pump the chamber down to a deep vacuum for every batch adds significant time to the overall process. This lower throughput makes VIM less suitable for the high-volume production of common metals.

How to Apply This to Your Goal

Choosing a melting technology depends entirely on the final requirements of your material. The cost and complexity of VIM are only justified when the application demands the highest level of metallurgical quality.

- If your primary focus is ultimate performance and reliability (e.g., superalloys for jet engines, medical implants): VIM is the industry standard, as its ability to minimize impurities is non-negotiable for preventing material failure.

- If your primary focus is working with reactive metals (e.g., titanium, zirconium, specialty alloys): VIM is essential, as melting these materials in the presence of air would lead to catastrophic contamination and ruin their properties.

- If your primary focus is cost-effective, high-volume production (e.g., standard steel, cast iron, aluminum alloys): VIM is complete overkill. A simpler and faster air-melt induction furnace is the appropriate and economical choice.

Ultimately, vacuum induction melting is a specialized tool for a specialized job: creating the cleanest, most precise, and highest-performing metals possible.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Core Principle | Fusion of electromagnetic induction heating and vacuum metallurgy. |

| Primary Benefit | Production of ultra-high purity metals with precise chemical composition. |

| Ideal For | Superalloys, reactive metals (titanium), medical implants, and other high-performance applications. |

| Main Limitation | Higher cost and complexity compared to air-melting processes. |

Need to produce metals with ultimate purity and performance?

The principles of vacuum induction melting are critical for applications where material failure is not an option. KINTEK specializes in advanced lab equipment, including systems for high-purity metallurgy. Our expertise can help you select the right technology to meet your specific material goals, whether for R&D or production.

Contact our experts today to discuss how we can support your high-performance metal production needs.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting