In essence, vapor deposition is a family of manufacturing processes used to apply extremely thin, high-performance coatings to an object. This is achieved by converting a solid or liquid coating material into a vapor within a vacuum chamber, allowing it to travel and then solidify onto the target object’s surface, known as the substrate.

The fundamental principle of vapor deposition is transformation and transport. A material is converted into a gaseous phase, transported to a substrate, and then condensed or reacted back into a solid state to form a functional film. The key differentiator between methods is how the vapor becomes a solid—either through a physical process or a chemical one.

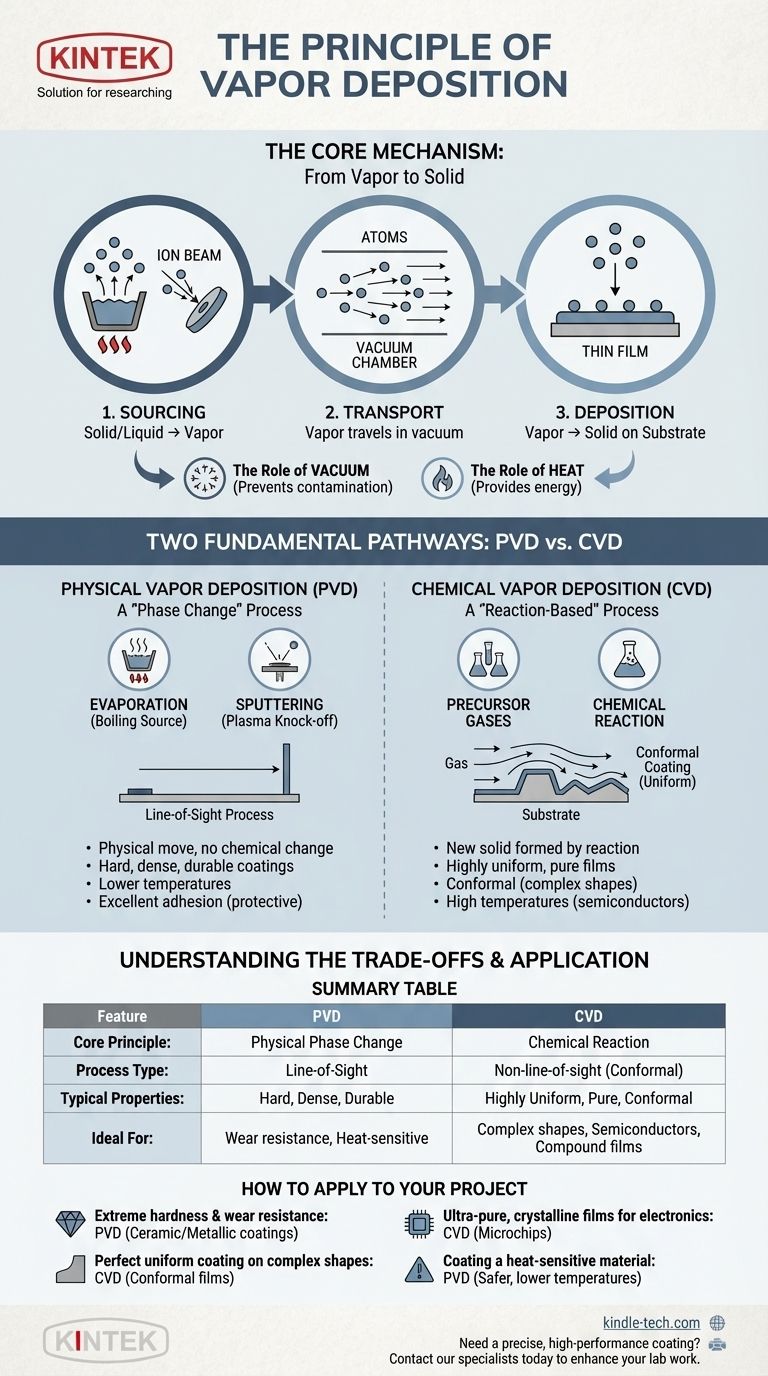

The Core Mechanism: From Vapor to Solid

Vapor deposition isn't a single technique but a foundational concept built on a few key steps. Understanding this sequence is crucial to grasping how it works.

The Three Essential Steps

- Sourcing: A material (the "source") is converted into a vapor. This can be done by heating it until it evaporates or by bombarding it with ions to knock atoms loose.

- Transport: The resulting vapor travels through a controlled, low-pressure (vacuum) environment from the source to the substrate. The vacuum is critical for preventing contamination from air and ensuring a clear path.

- Deposition: The vapor reaches the substrate and converts back into a solid, forming a thin, uniform film. This final step is where the major techniques diverge.

The Role of Vacuum and Heat

Nearly all vapor deposition processes occur in a vacuum. This removes unwanted particles that could contaminate the film or interfere with the vapor's path.

Heat is the engine of the process. It provides the energy needed to either vaporize the source material or to drive the chemical reactions on the substrate's surface.

The Two Fundamental Pathways: PVD vs. CVD

The primary distinction in vapor deposition lies in whether the process is physical or chemical. This choice dictates the equipment, materials, and final properties of the coating.

Physical Vapor Deposition (PVD): A "Phase Change" Process

Physical Vapor Deposition (PVD) is a physical process, much like water vapor condensing on a cold glass. The coating material itself is physically moved from the source to the substrate without a chemical change.

The two main PVD methods are evaporation and sputtering. Evaporation involves heating the source material until it boils into a vapor, which then condenses on the substrate. Sputtering uses a high-energy plasma to knock atoms off the source material, which then deposit onto the substrate.

PVD is fundamentally a line-of-sight process where atoms travel in a straight line from the source to the target.

Chemical Vapor Deposition (CVD): A "Reaction-Based" Process

Chemical Vapor Deposition (CVD) is a chemical process where the coating is not simply moved, but created on the substrate's surface.

In CVD, one or more precursor gases are introduced into the chamber. When these gases come into contact with the heated substrate, they undergo a chemical reaction or decomposition, forming a new solid material that deposits as a film. The film is a chemical product of the reaction, not the original precursor material.

Because the process relies on gas filling the chamber, CVD can produce highly uniform (conformal) coatings even on complex, non-flat shapes.

Understanding the Trade-offs

Choosing between PVD and CVD depends entirely on the desired outcome, the materials involved, and the geometry of the part being coated.

When to Choose PVD

PVD excels at depositing very hard, dense, and durable coatings. It is the go-to process for materials with extremely high melting points that are difficult to vaporize.

Because it can often be performed at lower temperatures than CVD, PVD is suitable for coating materials that cannot withstand intense heat. Its excellent adhesion makes it ideal for protective coatings.

When to Choose CVD

CVD's primary advantage is its ability to create exceptionally uniform and pure films that conform perfectly to intricate surfaces. This makes it indispensable in the semiconductor industry.

The final film is a new material formed by a reaction, allowing for the creation of compounds (like silicon nitride) that would be impossible to deposit with PVD. However, the high temperatures required for many CVD processes can limit the types of substrates that can be used.

How to Apply This to Your Project

Your choice between PVD and CVD should be driven by the specific properties you need in the final product.

- If your primary focus is extreme hardness and wear resistance: PVD is often the ideal choice for depositing ceramic or metallic coatings on tools and components.

- If your primary focus is a perfectly uniform coating on a complex shape: CVD is superior due to the way precursor gases can reach every nook and cranny of a surface.

- If your primary focus is creating ultra-pure, crystalline films for electronics: CVD is the undisputed industry standard for manufacturing microchips.

- If your primary focus is coating a heat-sensitive material: PVD generally operates at lower temperatures and is the safer option to avoid damaging the substrate.

Understanding the core difference between physical condensation and chemical reaction is the key to selecting the right vapor deposition process for your material challenge.

Summary Table:

| Feature | Physical Vapor Deposition (PVD) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Core Principle | Physical phase change (evaporation/sputtering) | Chemical reaction on the substrate |

| Process Type | Line-of-sight | Non-line-of-sight (conformal) |

| Typical Coating Properties | Hard, dense, durable coatings | Highly uniform, pure, conformal coatings |

| Ideal For | Wear resistance, heat-sensitive substrates | Complex shapes, semiconductors, compound films |

Need a precise, high-performance coating for your lab equipment or components?

At KINTEK, we specialize in providing advanced lab equipment and consumables for vapor deposition processes. Whether your project requires the extreme hardness of a PVD coating or the perfect conformity of a CVD film, our experts can help you select the right solution to enhance performance, durability, and functionality.

Contact our specialists today to discuss your specific coating challenges and discover how KINTEK can add value to your laboratory work.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating