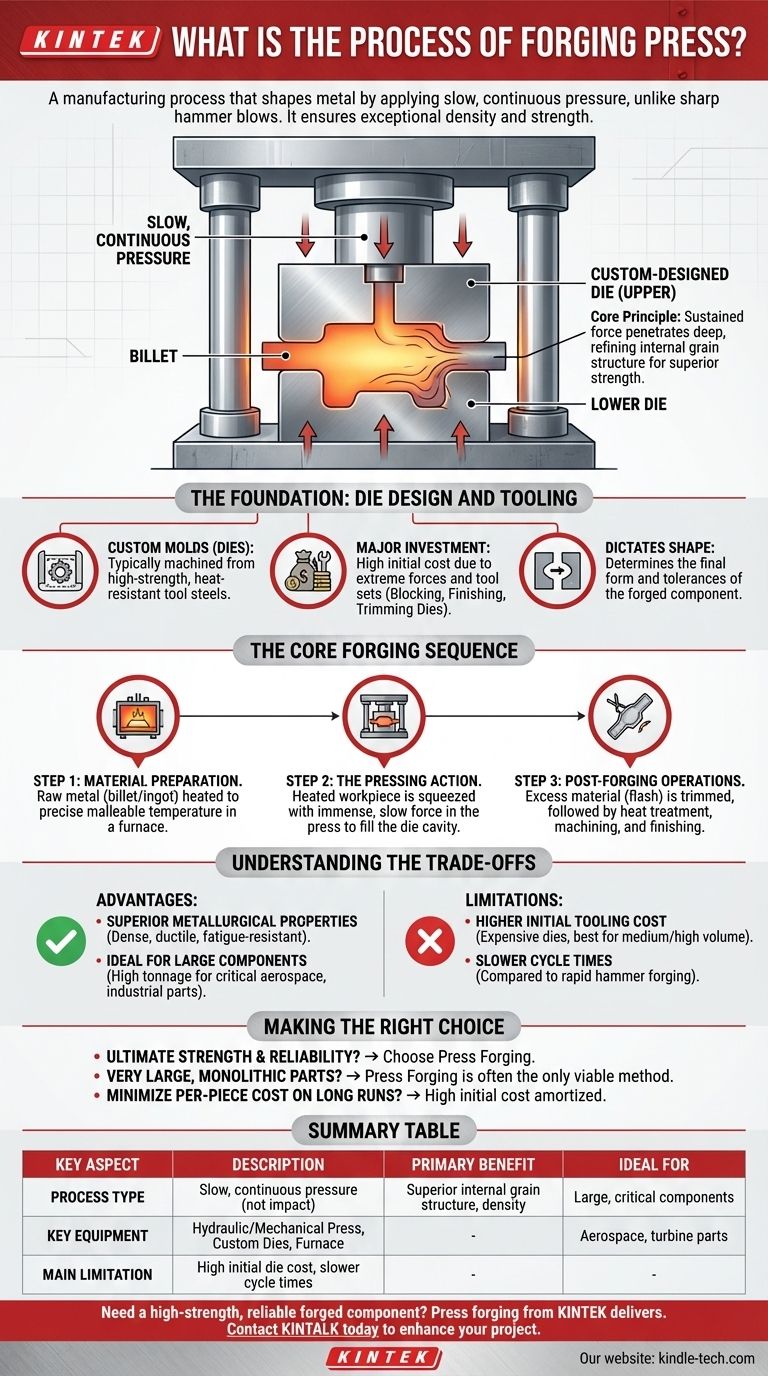

In short, press forging is a manufacturing process that shapes metal by applying slow, continuous pressure using a mechanical or hydraulic press. Unlike the sharp blows of hammer forging, this controlled squeezing action deforms the metal workpiece, forcing it to conform to the shape of a custom-designed die.

The core principle of press forging is its use of sustained, controlled force. This method penetrates deep into the metal, refining its internal grain structure to produce components with exceptional density, minimal voids, and superior mechanical strength, especially for large and critical applications.

The Foundation: Die Design and Tooling

The success of any press forging operation begins long before metal is heated. The design and creation of the dies are the most critical and cost-intensive phase.

The Role of Dies

Dies are the custom molds that dictate the final shape of the forged component. They are typically machined from high-strength, heat-resistant tool steels capable of withstanding immense, repeated pressure and high temperatures.

Why Tooling is a Major Investment

The reference to high die costs is a critical point. Unlike casting molds, forging dies must endure extreme forces. The initial investment is higher because it often includes a set of tools, not just a single mold.

This set frequently includes blocking dies for initial shaping, finishing dies for final geometry, and trimming dies used in a later step to shear away excess material, known as flash.

The Core Forging Sequence

Once the tooling is complete, the production process follows a clear, sequential path from raw material to a near-net-shape part.

Step 1: Material Preparation

The process begins with a raw piece of metal, often a billet or ingot. This workpiece is heated in a furnace to a precise temperature, making it malleable and plastic but not molten.

This temperature control is critical; too cold, and the metal may crack under pressure, while too hot, and its metallurgical properties could be compromised.

Step 2: The Pressing Action

The heated workpiece is placed on the lower die within the forging press. The press then activates, moving a ram to slowly squeeze the metal with immense force.

This deliberate pressure forces the metal to flow and fill every cavity of the die impression. The slow application of force ensures deep and uniform deformation throughout the material's entire volume.

Step 3: Post-Forging Operations

After the pressing is complete, the part is removed. It often has a small amount of excess material (flash) that squeezed out between the die halves.

This flash is removed in a secondary operation, often using the dedicated trimming dies mentioned earlier. The part may then undergo further processes like heat treatment to optimize strength, machining for tight tolerances, and surface finishing.

Understanding the Trade-offs

Press forging is a powerful process, but it is not the universal solution. Its advantages are balanced by specific limitations that make it suitable for certain applications over others.

Advantage: Superior Metallurgical Properties

The slow, continuous pressure refines the metal's internal grain structure, aligning it with the component's shape. This results in parts with exceptional density, ductility, and fatigue resistance compared to castings or machined parts.

Advantage: Ideal for Large Components

Hydraulic presses can generate enormous tonnage, making press forging one of the only viable methods for producing very large components, such as aircraft structural parts, turbine disks, and heavy industrial equipment.

Limitation: Higher Initial Tooling Cost

As noted, the robust and complex nature of forging dies makes the initial setup expensive. This process is most cost-effective for medium to high-volume production runs where the tooling cost can be amortized across many parts.

Limitation: Slower Cycle Times

Compared to the rapid impacts of hammer forging, the deliberate squeezing action of a press results in a slower production rate. This makes it less suitable for very high-volume, low-cost commodity items.

Making the Right Choice for Your Application

Selecting the correct manufacturing process depends entirely on your project's priorities.

- If your primary focus is ultimate strength and reliability: Press forging is the superior choice for critical components where internal integrity cannot be compromised.

- If your primary focus is producing very large, monolithic parts: Press forging is often the only feasible method to achieve the necessary deformation and material properties at that scale.

- If your primary focus is minimizing per-piece cost on a long production run: The high initial tooling cost of press forging can be justified, delivering strong, near-net-shape parts that require less subsequent machining.

Ultimately, press forging is a deliberate choice for applications where performance and internal quality are paramount.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Manufacturing using slow, continuous pressure (not impact) |

| Primary Benefit | Superior internal grain structure, density, and strength |

| Key Equipment | Hydraulic/Mechanical Press, Custom Dies, Furnace |

| Ideal For | Large, critical components (e.g., aerospace, turbine parts) |

| Main Limitation | High initial die cost, slower cycle times |

Need a high-strength, reliable forged component?

Press forging from KINTEK delivers the exceptional density and mechanical properties your critical applications demand. Our expertise in lab and industrial equipment manufacturing ensures your parts meet the highest standards for performance and reliability.

Contact KINTALK today to discuss how our forging solutions can enhance your project's strength and durability.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Anti-Cracking Press Mold for Lab Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the difference between hot mounting and cold mounting? Choose the Right Method for Your Sample

- How should a sample be installed onto the sample holder? Ensure Mechanical Stability & Electrical Integrity

- How should an RVC sheet be handled and set up during an experiment? Ensure Precision and Data Integrity

- What are the advantages of an electrolytic polishing device for EK-181 steel TEM samples? Ensure Peak Sample Integrity

- What role do laboratory grinding and polishing systems play in nitriding? Ensure Superior Mirror-Finish & Ion Penetration