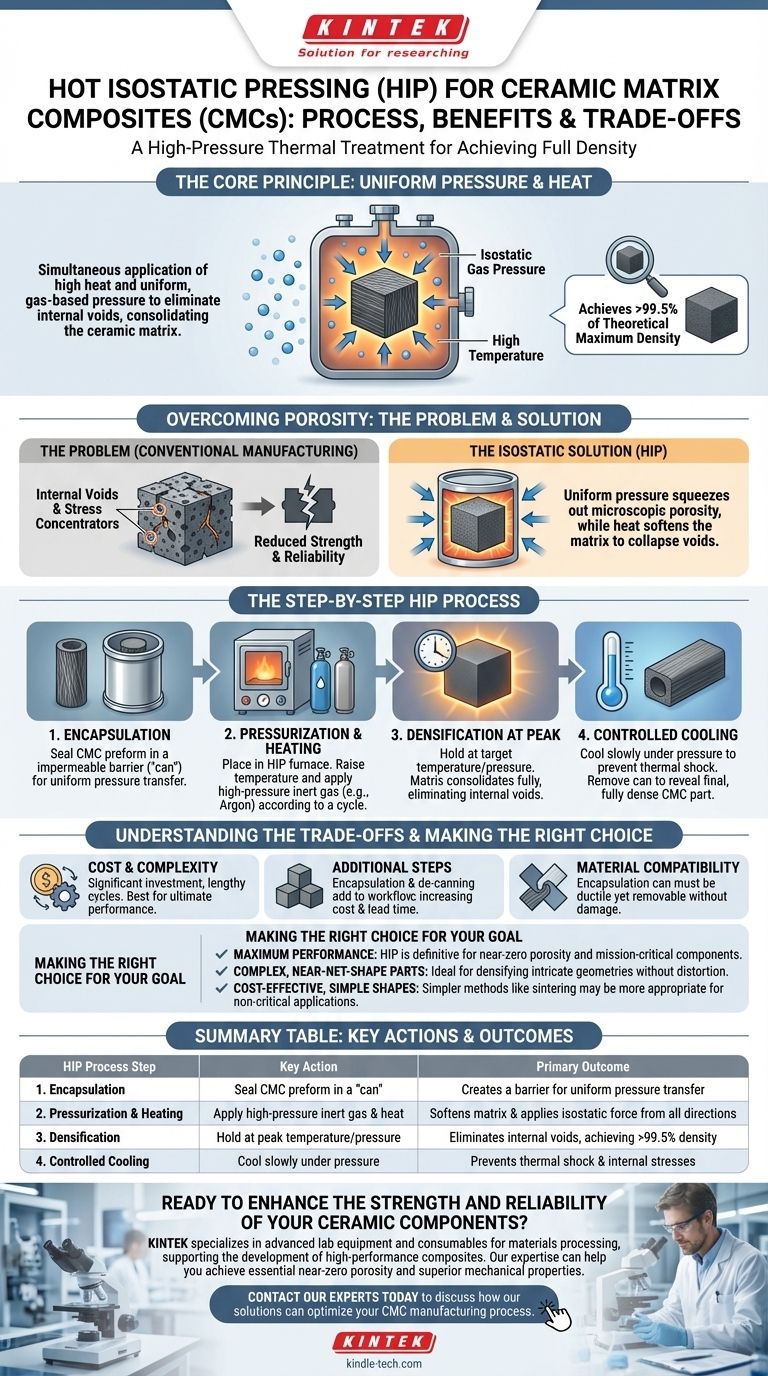

Hot Isostatic Pressing (HIP) is a high-pressure thermal treatment used to create fully dense ceramic matrix composites (CMCs). The process simultaneously applies high temperature and uniform, gas-based pressure to a component, effectively eliminating internal voids and consolidating the ceramic matrix around its reinforcing fibers.

The core principle of Hot Isostatic Pressing is the use of an inert gas, like argon, to apply uniform pressure from all directions. This "isostatic" pressure, combined with high heat, squeezes out microscopic porosity, resulting in a finished material with superior density, strength, and structural integrity.

The Core Principle: Overcoming Porosity

The Problem of Internal Voids

In conventional manufacturing, tiny pores or voids can remain trapped within the ceramic material after initial processing. These voids act as stress concentrators and are the primary points of failure, significantly reducing the material's overall strength and reliability.

The Isostatic Solution

Hot Isostatic Pressing solves this by placing the CMC component inside a sealed pressure vessel. The vessel is then filled with a high-pressure inert gas, which acts as a pressure-transfer medium.

Because gas pressure is uniform, it pushes on the component equally from every single direction. This is fundamentally different from mechanical pressing, which applies force along a single axis.

The Role of High Temperature

Simultaneously, the component is heated to a temperature high enough to soften the ceramic matrix on a microscopic level. This allows the material to flow and deform under the immense external pressure, collapsing the internal voids.

The Step-by-Step HIP Process for CMCs

1. Encapsulation

The CMC preform (the initial structure of fibers and partially processed matrix) is typically sealed within a metallic or glass container, often called a "can." This can acts as a solid, impermeable barrier that the gas can press against, transferring the force to the ceramic part inside.

2. Pressurization and Heating

The encapsulated component is placed inside the HIP furnace. The system is sealed, and both temperature and pressure are raised according to a precise, pre-programmed cycle tailored to the specific material.

3. Densification at Peak Conditions

The component is held at the target temperature and pressure for a specific duration. During this "hold time," the combination of heat and pressure forces the ceramic matrix to consolidate fully, achieving a density that is often greater than 99.5% of its theoretical maximum.

4. Controlled Cooling

After the hold time is complete, the component is cooled under pressure. This controlled cooling is critical to prevent thermal shock and the formation of new internal stresses. Once cooled, the outer can is removed, revealing the final, fully dense CMC part.

Understanding the Trade-offs

Process Cost and Complexity

HIP systems are a significant capital investment, and the process cycles can be lengthy. This makes it more expensive than conventional sintering and best reserved for components where ultimate performance is the primary driver.

Additional Processing Steps

The need for encapsulation and subsequent de-canning adds steps to the manufacturing workflow. This can increase both cost and lead time compared to processes that do not require this containment.

Material Compatibility

The material used for the encapsulation can must be carefully chosen. It needs to be ductile enough to deform at the HIP temperature without failing, yet easily removable after the process is complete without damaging the finished part.

Making the Right Choice for Your Goal

When deciding if HIP is the correct process, consider the final application of your component.

- If your primary focus is maximum performance and reliability: HIP is the definitive choice for creating mission-critical components with near-zero porosity and superior mechanical properties.

- If your primary focus is producing complex, near-net-shape parts: The uniform pressure of HIP is ideal for densifying intricate geometries without the risk of distortion common in other methods.

- If your primary focus is cost-effective production of simple shapes: For non-critical applications, simpler and less expensive methods like conventional sintering may be a more appropriate choice.

By leveraging the unique power of uniform heat and pressure, Hot Isostatic Pressing transforms advanced ceramic composites into components capable of withstanding the most demanding environments.

Summary Table:

| HIP Process Step | Key Action | Primary Outcome |

|---|---|---|

| 1. Encapsulation | Seal CMC preform in a 'can' | Creates a barrier for uniform pressure transfer |

| 2. Pressurization & Heating | Apply high-pressure inert gas (e.g., Argon) and heat | Softens matrix and applies isostatic force from all directions |

| 3. Densification | Hold at peak temperature/pressure | Eliminates internal voids, achieving >99.5% density |

| 4. Controlled Cooling | Cool slowly under pressure | Prevents thermal shock and internal stresses |

Ready to enhance the strength and reliability of your ceramic components?

KINTEK specializes in advanced lab equipment and consumables for materials processing, including technologies that support the development of high-performance composites. Our expertise can help you achieve the near-zero porosity and superior mechanical properties essential for mission-critical applications.

Contact our experts today to discuss how our solutions can optimize your CMC manufacturing process.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What critical processing conditions does a Vacuum Hot-Press Sintering Furnace provide? Achieve High-Performance Composites

- Why must vacuum hot pressing equipment have high-tonnage pressure control for WC/Cu-Zr-Ti amorphous composites?