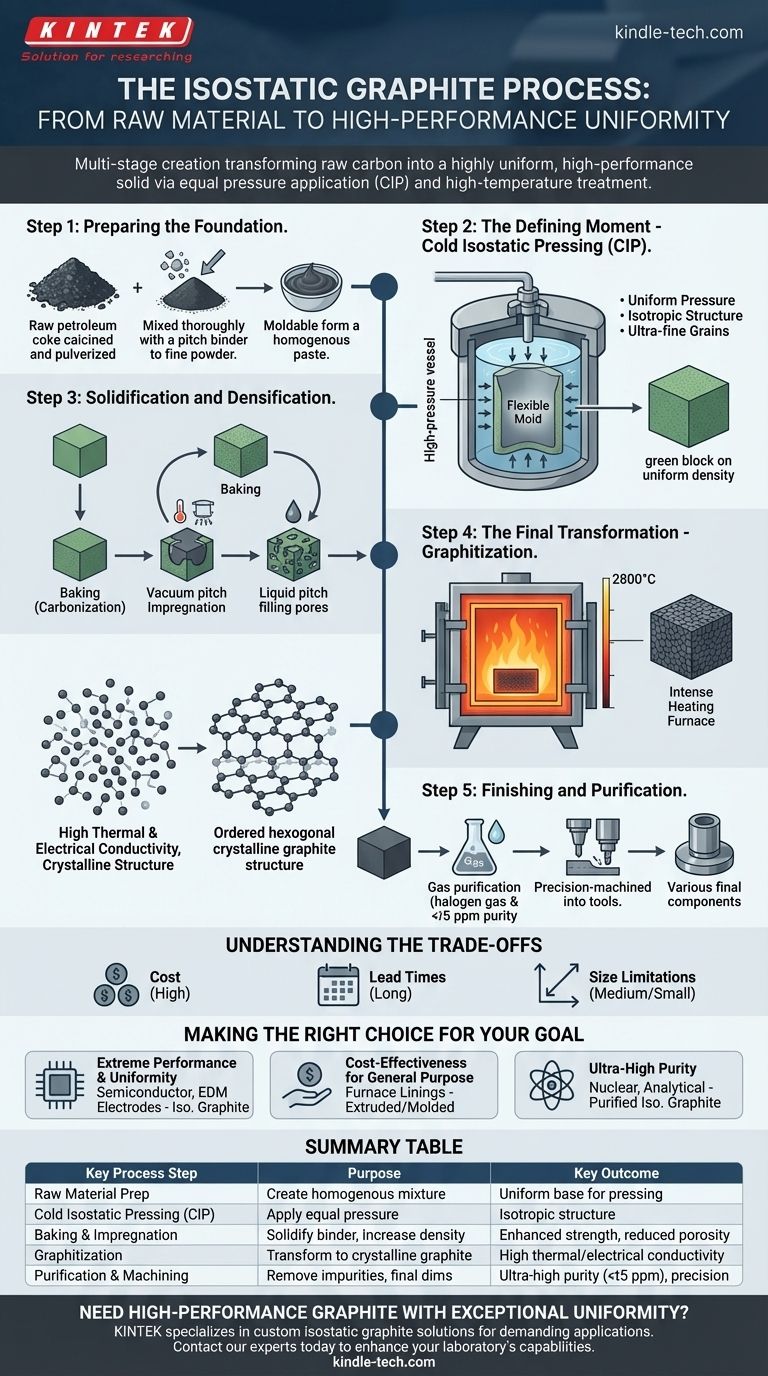

At its core, the creation of isostatic graphite is a multi-stage process designed to transform raw carbon materials into a highly uniform, high-performance solid. The journey involves preparing a fine powder from coke and a pitch binder, compressing it under immense and equal pressure from all sides, and then using a series of high-temperature treatments to develop its final, stable graphitic structure.

The defining characteristic of this process is Cold Isostatic Pressing (CIP), which applies pressure uniformly from all directions. This unique forming method is directly responsible for creating isostatic graphite's exceptionally uniform (isotropic) structure and ultra-fine grains, which are the source of its superior mechanical and thermal properties.

The Manufacturing Journey: From Raw Material to Finished Component

The production of isostatic graphite is a controlled and deliberate sequence. Each step is engineered to contribute to the final material's exceptional characteristics, which are required for some of the world's most advanced equipment.

Step 1: Preparing the Foundation

The process begins with high-quality petroleum or pitch coke. This raw material is calcined (heat-treated) and then pulverized into a very fine powder.

This powder is then meticulously mixed and kneaded with a pitch binder. The goal is to create a homogenous, moldable paste where every coke particle is uniformly coated.

Step 2: The Defining Moment - Cold Isostatic Pressing (CIP)

The prepared mixture is sealed in a flexible mold and submerged in a fluid within a high-pressure vessel.

Pressure is then applied to the fluid, which transmits it equally and simultaneously to all surfaces of the mold. This is the "isostatic" part of the process.

Unlike extrusion or single-axis molding which create directional grain, CIP ensures the material has no preferred orientation. The result is a "green" block with a remarkably uniform density and an isotropic (non-directional) internal structure.

Step 3: Solidification and Densification

The green block undergoes an initial baking stage, often called carbonization. This slow heating process solidifies the block by converting the pitch binder into solid carbon, creating a hard, porous carbon material.

To achieve maximum density and strength, this baked block is often subjected to pitch impregnation. It is placed in a vacuum, flooded with liquid pitch to fill the pores, and then re-baked to convert the new pitch into carbon. This cycle can be repeated multiple times.

Step 4: The Final Transformation - Graphitization

The densified carbon block is heated in an inert atmosphere to extremely high temperatures, typically between 2500°C and 2800°C.

This intense heat treatment forces the disordered carbon atoms to rearrange into the ordered, hexagonal crystalline structure of graphite. This step is what develops the material's signature high thermal and electrical conductivity.

Step 5: Finishing and Purification

After graphitization, the large graphite block is ready for final processing. This often begins with an optional purification step, where the block is heated again in a halogen gas atmosphere to remove impurities, achieving purity levels as high as <5 parts per million (ppm).

Finally, the purified block is machined with high precision into the final components specified by the customer. A final surface treatment may be applied before inspection and shipment.

Understanding the Inherent Trade-offs

Isostatic graphite's superior properties come from a complex and resource-intensive process. It is critical to understand the associated trade-offs when specifying this material.

The Cost of Performance

The specialized equipment, particularly the CIP vessel and the high-temperature graphitizing furnaces, along with the multi-step nature of the process, make isostatic graphite significantly more expensive than other grades like extruded or vibration-molded graphite.

Longer Manufacturing Lead Times

The process is inherently slow. Each baking, impregnation, and graphitization cycle can take weeks to complete. This means lead times for custom-produced blocks are considerable compared to more conventional materials.

Size and Geometry Limitations

The dimensions of the isostatic press chamber place an upper limit on the size of the initial block that can be produced. While large blocks are possible, the process is generally better suited for producing small to medium-sized components where material uniformity is paramount.

Making the Right Choice for Your Goal

Selecting the correct grade of graphite is a matter of matching the material's engineered properties to the demands of your application.

- If your primary focus is extreme performance and material uniformity: Isostatic graphite is the correct choice, as its manufacturing process guarantees isotropic properties for demanding thermal and mechanical applications like semiconductor crucibles or EDM electrodes.

- If your primary focus is cost-effectiveness for general-purpose applications: An extruded or molded graphite will likely provide sufficient performance for applications like furnace linings or casting molds at a lower price point.

- If your primary focus is ultra-high purity for nuclear or analytical use: You must specify a grade of isostatic graphite that has undergone the optional high-temperature purification step to remove catalytic and neutron-absorbing impurities.

By understanding this manufacturing process, you can confidently specify a material whose properties are precisely engineered for your specific challenge.

Summary Table:

| Key Process Step | Purpose | Key Outcome |

|---|---|---|

| Raw Material Preparation | Create homogenous coke/pitch mixture | Uniform base for pressing |

| Cold Isostatic Pressing (CIP) | Apply equal pressure from all directions | Isotropic (non-directional) structure |

| Baking & Impregnation | Solidify binder and increase density | Enhanced strength and reduced porosity |

| Graphitization | Transform carbon to crystalline graphite | High thermal/electrical conductivity |

| Purification & Machining | Remove impurities and achieve final dimensions | Ultra-high purity (<5 ppm) and precision |

Need high-performance graphite components with exceptional uniformity? KINTEK specializes in premium lab equipment and consumables, including custom graphite solutions for demanding applications like semiconductor manufacturing, EDM electrodes, and high-temperature furnaces. Our expertise ensures you get the right material properties for your specific challenge. Contact our experts today to discuss how our isostatic graphite can enhance your laboratory's capabilities and performance.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the basic principle of graphite furnace atomic absorption spectroscopy? Achieve Ultra-Trace Element Detection

- What is the function of the graphite furnace? Achieve Extreme Heat for Analysis & Materials Processing

- What are the disadvantages of graphite furnace? Key Limitations and Operational Costs

- What is the temperature range of a graphite furnace? Unlock up to 3000°C for advanced materials processing.

- What is the high temperature graphite material? The Ultimate Solution for Extreme Heat Applications

- What are the advantages of graphite? Unlock Superior Performance in High-Temperature Processes

- What is isostatic graphite? The Ultimate Material for High-Tech and High-Temperature Applications

- What is the maximum working temperature of graphite? Unlock High-Temp Performance with the Right Atmosphere