At its core, sintering is a heat treatment process used in powder metallurgy to transform a fragile, compressed powder shape into a strong, solid component. By heating the material in a furnace to a temperature just below its melting point, the individual metal particles fuse, creating strong metallurgical bonds that give the part its final strength and structural integrity.

Sintering is not about melting metal. It is the controlled process of using thermal energy to drive solid-state diffusion, causing adjacent powder particles to bond and densify, thereby converting a weakly-held powder compact into a robust, engineered part.

The Role of Sintering in Powder Metallurgy

Sintering is the critical transformation step that gives powder metal parts their useful mechanical properties. Without it, a compacted part would simply crumble.

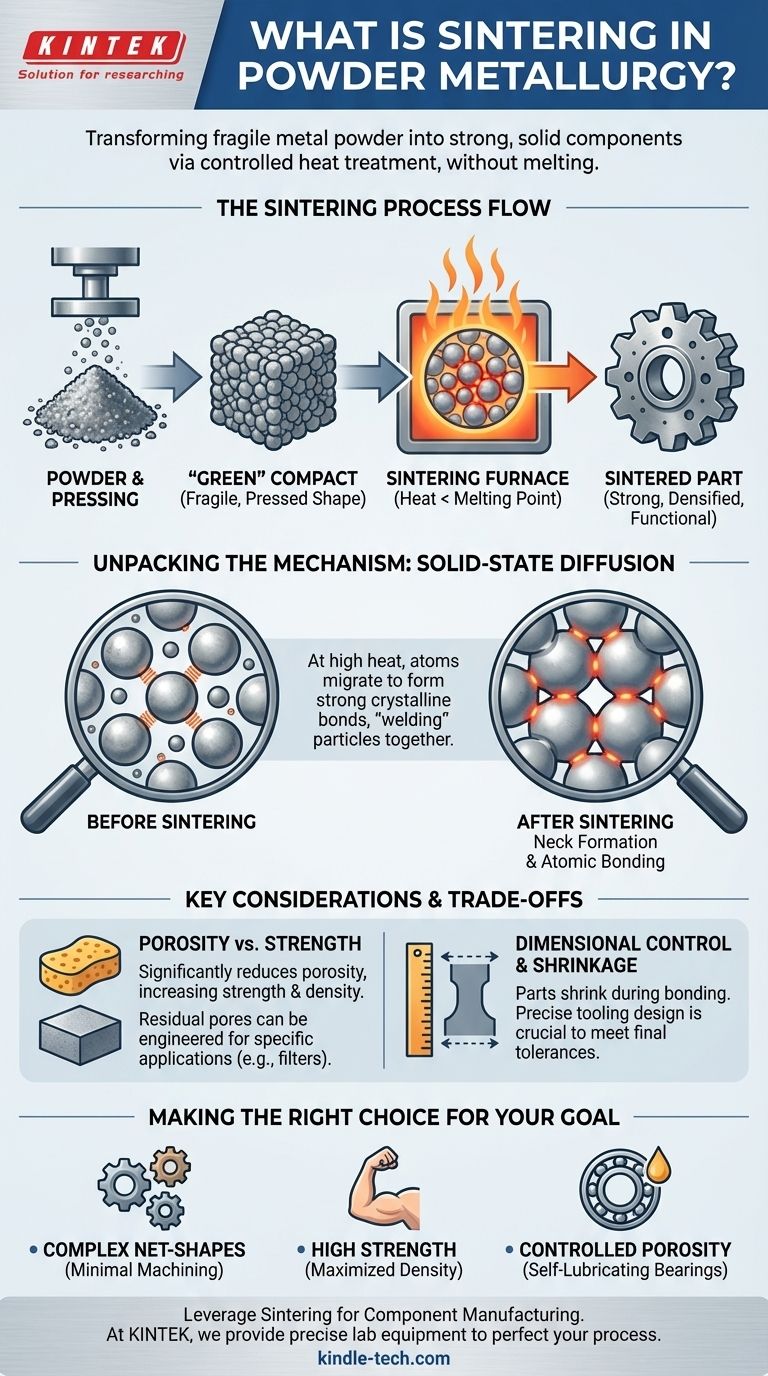

From "Green" Compact to Finished Part

Before sintering, metal powder is pressed into a mold under high pressure. The resulting shape is called a "green" compact.

This green compact is fragile, held together only by the mechanical interlocking of the particles. It has the desired shape but lacks the strength needed for any application. Sintering is what provides this strength.

The Goal: Strength Through Bonding

The primary objective of sintering is to heat the green compact in a controlled furnace. This thermal energy causes the atoms at the contact points of the particles to diffuse across the boundaries.

This atomic transport creates strong, crystalline bonds, effectively "welding" the particles together on a microscopic level. The result is a significant increase in the part's hardness, strength, and density.

Unpacking the Sintering Mechanism

The process works through a principle known as solid-state diffusion, which occurs without ever melting the bulk material.

The Power of Solid-State Diffusion

At high temperatures, atoms become more mobile. During sintering, atoms from adjacent particles migrate and rearrange to form connections, or "necks," at their points of contact.

Think of how two ice cubes left in a glass of water will slowly fuse at their contact points. Sintering achieves a similar effect for metal particles, but at much higher temperatures and resulting in a far stronger bond.

The Critical Role of Temperature

The sintering temperature is precisely controlled to be below the melting point of the primary metal.

This is crucial because it allows the part to densify and strengthen while maintaining its precise, compacted shape. If the material were to melt, dimensional control would be lost entirely.

A Controlled Furnace Environment

Sintering is performed in specialized furnaces with a carefully controlled atmosphere. This atmosphere is typically inert or reducing, preventing oxidation of the metal surfaces, which would otherwise inhibit proper bonding between particles.

Understanding the Trade-offs

While powerful, the sintering process involves key considerations that impact the final product.

Porosity vs. Strength

Sintering significantly reduces the empty space (porosity) between powder particles, but it rarely eliminates it completely.

This residual porosity means that a sintered part is often less dense and may have lower ultimate strength than a part made from solid, wrought metal. However, this porosity can be a design advantage for creating products like self-lubricating bearings or filters.

Dimensional Control

As the particles fuse and the pores shrink, the entire component undergoes a degree of shrinkage. This change must be accurately predicted and accounted for during the initial design of the compaction tooling to ensure the final part meets its required dimensional tolerances.

Making the Right Choice for Your Goal

Understanding sintering allows you to leverage the powder metallurgy process to achieve specific engineering outcomes.

- If your primary focus is producing complex, net-shape parts: Sintering is ideal, as it allows you to form intricate geometries that require little to no subsequent machining.

- If your primary focus is achieving high strength: Careful control over powder composition, compaction pressure, and sintering time, temperature, and atmosphere is critical to maximize density.

- If your primary focus is creating controlled porosity: Sintering is a unique process that enables the deliberate engineering of porous materials for applications like filters and oil-impregnated bearings.

Ultimately, sintering is the essential process that unlocks the potential of metal powders, transforming them into precise and durable engineered components.

Summary Table:

| Sintering Aspect | Key Detail |

|---|---|

| Primary Goal | Transform a fragile 'green' compact into a strong, solid part. |

| Core Mechanism | Solid-state diffusion bonds particles at temperatures below melting. |

| Key Outcome | Increased strength, hardness, and density of the final component. |

| Critical Factor | Controlled furnace atmosphere to prevent oxidation and ensure bonding. |

| Design Consideration | Predictable part shrinkage must be accounted for in tooling design. |

Ready to leverage sintering for your component manufacturing?

At KINTEK, we specialize in the precise lab equipment and consumables needed to perfect your powder metallurgy processes. Whether you are developing complex net-shape parts, optimizing for maximum strength, or engineering controlled porosity, our expertise and products support your goals.

Contact our experts today to discuss how we can help you achieve superior results in your laboratory.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

People Also Ask

- What does an annealing furnace do? Relieve Stress and Improve Material Workability

- Why is a vacuum drying oven required for Si-FG post-treatment? Preserving Chemical Integrity of Graphene

- What is the difference between a vacuum furnace and an inert gas furnace? Choose the Right Heat Treatment Process

- What does sintering do? Transform Powder into Strong, Dense Components

- What is the most commonly used quenching medium? Discover Why Oil is the Metallurgy Workhorse

- What is a low temperature form of brazing? Discover Solid-State Joining for Heat-Sensitive Materials

- What are the essential steps in brazing operation? A Guide to Strong, Reliable Metal Joints

- What is the primary function of a vacuum brazing furnace for Niobium Permeators? Achieve High-Integrity Hermetic Seals