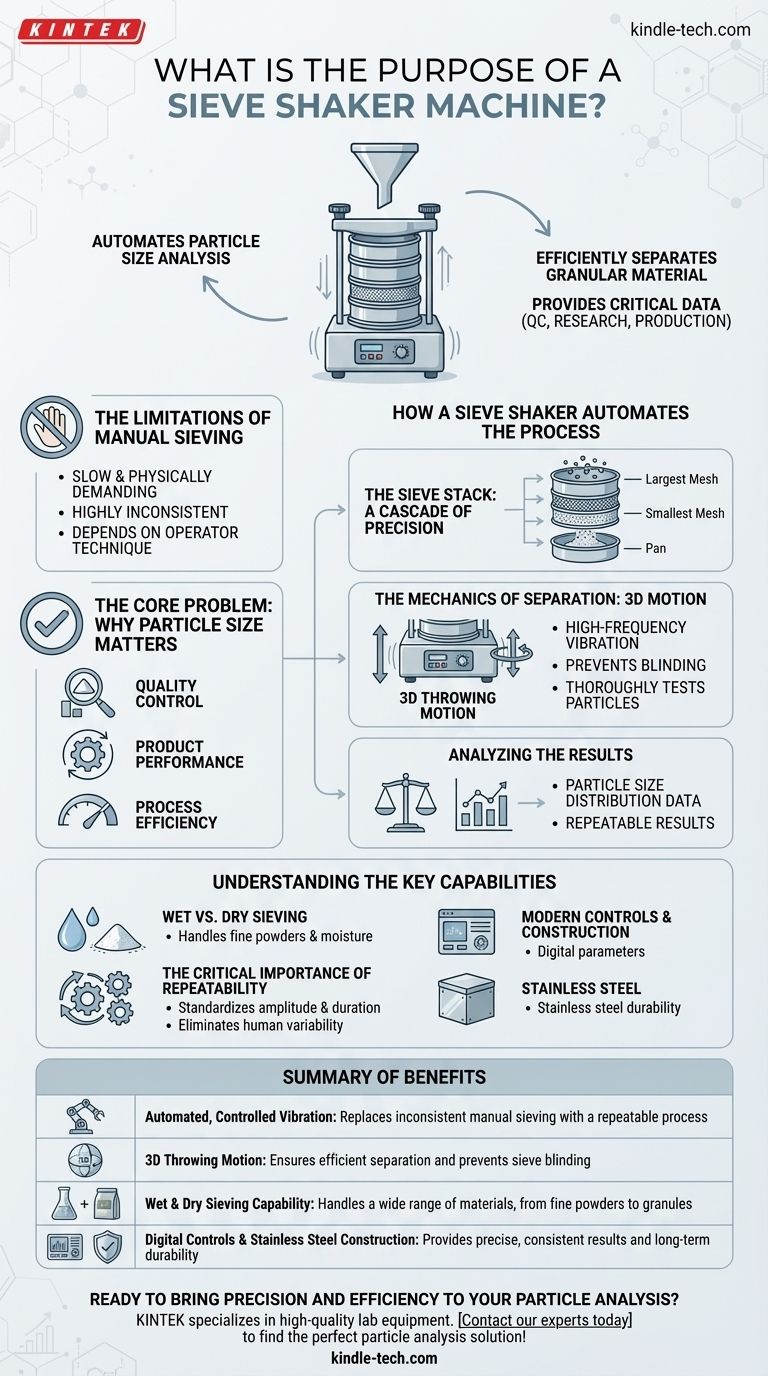

In short, a sieve shaker is a specialized instrument that automates the process of particle size analysis. It uses controlled vibration to agitate a stack of test sieves, efficiently separating granular material based on the size of its individual particles. This process provides critical data for quality control, research, and production across numerous industries.

While a sieve shaker physically separates particles by size, its true purpose is to replace inconsistent manual methods with an automated, highly repeatable process for particle size analysis. This provides the reliable data essential for modern quality control and research.

The Core Problem: Why Particle Size Matters

To understand the sieve shaker, you must first understand why particle size distribution is a critical variable. The size and range of particles in a material directly influence its physical properties, behavior, and quality.

From Quality Control to Product Performance

In manufacturing and research, particle size affects everything from a product's chemical reaction rate to its final texture. Consistent particle size ensures that concrete is strong, pharmaceuticals dissolve correctly, and food products have the desired consistency.

Without a reliable way to measure this, you cannot guarantee product quality or process efficiency.

The Limitations of Manual Sieving

Historically, particle analysis was done by hand. An operator would manually shake a sieve, a method that is slow, physically demanding, and highly inconsistent.

The results of manual sieving depend entirely on the individual operator's technique, duration, and force. This makes it impossible to achieve the repeatability required for modern scientific standards and quality assurance.

How a Sieve Shaker Automates the Process

A sieve shaker solves the problems of manual analysis by introducing mechanical precision and control. It transforms sieving from an art into a science.

The Sieve Stack: A Cascade of Precision

The process begins with a stack of test sieves. These are precision-woven mesh screens with certified aperture sizes, arranged vertically from the largest mesh opening at the top to the smallest at the bottom, with a solid pan at the base.

When the material sample is placed in the top sieve, the shaker's motion causes particles to cascade downward. A particle falls through successively smaller sieve openings until it is caught by a mesh it cannot pass through.

The Mechanics of Separation: 3D Motion

The shaker's effectiveness comes from its specialized movement. A high-frequency vibration motor drives the sieve stack in a controlled, 3D throwing motion, combining both vertical and orbital actions.

This motion ensures that every particle is continuously lifted and repositioned on the mesh screen. It prevents blinding (where particles block the openings) and guarantees that each particle is thoroughly tested against the apertures, providing a true and efficient separation.

Analyzing the Results

After the shaking cycle is complete, the machine is stopped. The material retained on each individual sieve is weighed.

This data allows you to calculate the particle size distribution of the sample, providing a precise percentage breakdown of the material by size range. Modern machines with integrated software can automate this analysis and reporting.

Understanding the Key Capabilities

Not all sieving tasks are the same. A sieve shaker's value lies in its flexibility and the reliability of its results.

Wet vs. Dry Sieving

Most materials can be analyzed in a dry state. However, for very fine powders or materials that tend to clump together due to static electricity or moisture, wet sieving is necessary.

In this process, a liquid (typically water) is used to disperse the particles and wash them through the sieve stack. A capable sieve shaker is designed to handle both wet and dry applications.

The Critical Importance of Repeatability

The single greatest advantage of a sieve shaker is repeatability. By standardizing the shaking amplitude, duration, and motion, the machine eliminates human variability.

This means that a test run today will yield the exact same results as a test run next year on an identical sample. This consistency is the foundation of any credible quality control program or research finding.

Modern Controls and Construction

Modern sieve shakers feature digital controls to precisely set and store testing parameters. They are typically built from durable materials like stainless steel to prevent sample contamination and ensure a long operational life in demanding industrial environments.

Making the Right Choice for Your Application

Selecting and using a sieve shaker depends entirely on your primary goal.

- If your primary focus is consistent production quality: Emphasize the machine's ability to deliver fast, repeatable results for ensuring product consistency batch after batch.

- If your primary focus is research and development: Prioritize a flexible machine that offers precise control over parameters and handles both wet and dry analysis for new materials.

- If your primary focus is operational efficiency: Focus on the significant gains in speed, accuracy, and reduced labor costs compared to tedious and error-prone manual sieving.

Ultimately, a sieve shaker gives you precise, actionable control over your material's fundamental physical properties.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Automated, Controlled Vibration | Replaces inconsistent manual sieving with a repeatable process |

| 3D Throwing Motion | Ensures efficient separation and prevents sieve blinding |

| Wet & Dry Sieving Capability | Handles a wide range of materials, from fine powders to granules |

| Digital Controls & Stainless Steel Construction | Provides precise, consistent results and long-term durability |

Ready to bring precision and efficiency to your particle analysis?

Whether your focus is on rigorous quality control, innovative R&D, or improving operational efficiency, the right sieve shaker is key to obtaining reliable data.

KINTEK specializes in high-quality lab equipment, including reliable sieve shakers designed to meet the demanding needs of modern laboratories. We provide the tools you need to ensure product consistency, accelerate research, and streamline your processes.

Contact our experts today to find the perfect particle analysis solution for your application!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits

- Can sieving be used to separate a solid substance from a liquid substance? Learn the Right Technique for Your Mixture

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What are the advantages and disadvantages of sieve analysis? A Guide to Cost-Effective Particle Sizing

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis