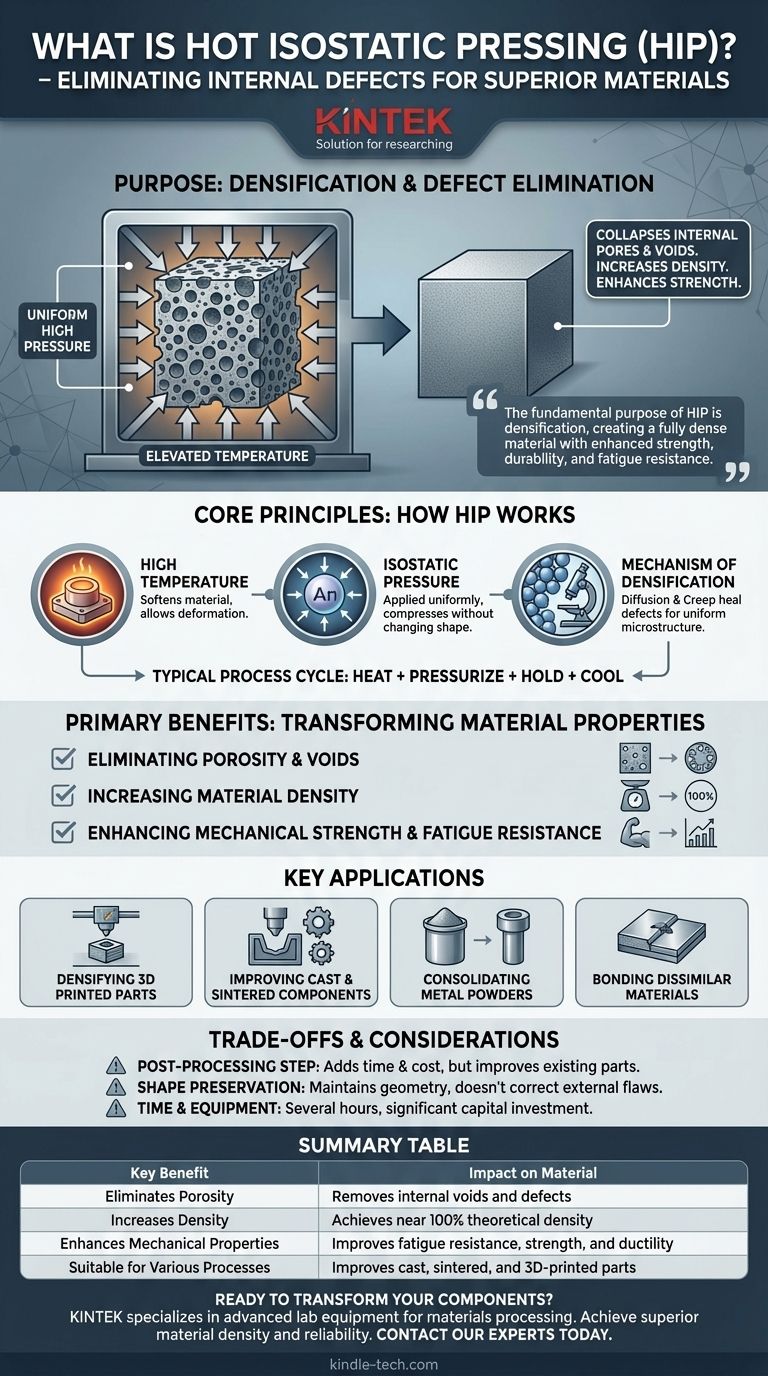

At its core, hot isostatic pressing (HIP) is a manufacturing process designed to eliminate internal defects from materials. It uses a combination of high, uniform pressure and elevated temperature to compress and fuse metals, ceramics, or composites, effectively removing microscopic voids and increasing the material's density. This results in components with vastly superior mechanical properties and reliability.

The fundamental purpose of HIP is densification. By subjecting a part to uniform, high-pressure gas at high temperatures, the process collapses internal pores and voids, creating a fully dense material with enhanced strength, durability, and fatigue resistance.

How Hot Isostatic Pressing Works: The Core Principles

To understand the benefits of HIP, it's essential to grasp its core mechanism. The process relies on the precise control of three key elements: temperature, pressure, and a controlled atmosphere.

The Role of High Temperature

The component is heated in the HIP chamber to a temperature below its melting point. This heat softens the material, making it pliable enough for plastic deformation to occur under pressure.

The Function of Isostatic Pressure

Simultaneously, the chamber is filled with a high-pressure inert gas, typically argon. This pressure is isostatic, meaning it is applied uniformly from all directions, ensuring the part is compressed without changing its net shape.

The Mechanism of Densification

The combination of heat and pressure causes the internal voids or pores within the material to collapse. At the atomic level, this pressure forces material to diffuse and creep into the empty spaces, permanently healing the defects and creating a solid, uniform microstructure.

The Typical Process Cycle

A standard HIP cycle involves loading parts into the vessel, heating them to the target temperature, pressurizing the chamber, holding these conditions for a set duration, and finally, a controlled depressurization and cooling phase. This entire process can be integrated with other heat treatment steps, such as quenching and aging, to consolidate manufacturing stages.

The Primary Benefits: Transforming Material Properties

The elimination of internal porosity is not just a cosmetic fix; it fundamentally transforms a material's performance characteristics, making it suitable for demanding applications.

Eliminating Porosity and Voids

The most direct outcome of HIP is the removal of internal defects. This is especially critical for parts made through casting, sintering, or additive manufacturing (3D printing), which are often prone to microscopic porosity.

Increasing Material Density

By collapsing voids, HIP drives the material toward 100% theoretical density. This uniform density is directly correlated with improved and more predictable material performance.

Enhancing Mechanical Strength and Fatigue Resistance

Pores act as stress concentration points where cracks can initiate and propagate. By eliminating these defects, HIP dramatically increases a component's fatigue resistance, ductility, and overall tensile strength.

Key Applications Across Manufacturing

HIP is not a standalone fabrication method but a powerful post-processing step that enhances parts made by other means.

Densifying 3D Printed (Additive) Parts

Additive manufacturing often creates parts with internal porosity or imperfect bonding between layers. HIP is a critical step to densify these components, making them suitable for high-stress applications in aerospace and medical industries.

Improving Cast and Sintered Components

Traditional casting and sintering can leave behind residual porosity. HIP is used to heal these internal flaws, salvaging parts that might otherwise be scrapped and upgrading their performance.

Consolidating Metal Powders

HIP can be used to consolidate metal powders into a fully dense solid. The powder is placed in a sealed metallic container or 'can,' which is then subjected to the HIP cycle, creating a "near-net-shape" part with properties that can exceed those of traditionally forged materials.

Bonding Dissimilar Materials

The intense pressure and heat of the HIP process can also be used to create strong, diffusion-based bonds between two or more different materials, enabling the creation of complex, clad components.

Understanding the Trade-offs and Considerations

While highly effective, HIP is a specific tool with its own set of operational realities. Understanding these is key to its proper application.

It Is a Post-Processing Step

HIP does not create a part; it improves an existing one. It adds time and cost to the overall manufacturing workflow, which must be justified by the need for enhanced material properties.

Shape Preservation, Not Reshaping

The isostatic nature of the pressure ensures that a part's overall geometry is maintained. It will not correct external dimensional inaccuracies or surface flaws; it only addresses internal defects.

Process Time and Equipment

HIP cycles can take several hours, and the equipment represents a significant capital investment. This makes the process most suitable for high-value components where performance and reliability are non-negotiable.

Making the Right Choice for Your Goal

Applying HIP should be a deliberate decision driven by specific performance requirements.

- If your primary focus is maximum performance for critical components: Use HIP to eliminate all internal defects in aerospace, medical, or energy components to guarantee reliability and fatigue life.

- If your primary focus is improving additively manufactured parts: Specify HIP as a mandatory post-processing step to achieve the mechanical properties required for functional, load-bearing applications.

- If your primary focus is creating fully dense parts from metal powders: Employ the powder metallurgy HIP route to produce near-net-shape parts with superior, uniform material properties.

- If your primary focus is salvaging cast parts with internal porosity: Implement HIP to heal casting defects, improving yield and ensuring the structural integrity of the final component.

Ultimately, hot isostatic pressing serves as a powerful final step to transform good components into exceptional ones by perfecting their internal structure.

Summary Table:

| Key Benefit | Impact on Material |

|---|---|

| Eliminates Porosity | Removes internal voids and defects |

| Increases Density | Achieves near 100% theoretical density |

| Enhances Mechanical Properties | Improves fatigue resistance, strength, and ductility |

| Suitable for Various Processes | Improves cast, sintered, and 3D-printed parts |

Ready to transform your components with hot isostatic pressing?

KINTEK specializes in advanced lab equipment and consumables for materials processing. Our expertise can help you integrate HIP technology to achieve superior material density, enhanced mechanical properties, and unparalleled reliability for your most critical components in aerospace, medical, and energy applications.

Contact our experts today to discuss how our solutions can meet your specific laboratory and manufacturing needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What is the role of a vacuum hot press furnace in TiC-steel composites? Achieve 99% Density with Precision

- What is spark plasma sintering process? Fast-Track to Dense, Fine-Grained Materials

- How does the precise temperature control of a vacuum hot press sintering furnace facilitate in-situ reactions in SiC/B4C?

- Why are graphite molds used during the vacuum hot-press sintering of MoSi2-based composite materials? Key Benefits

- How does vacuum hot pressing equipment improve the densification of metal-matrix composites? Achieve Over 90% Density

- What are the advantages of using a vacuum hot press furnace for sintering CNT/Cu composites? Superior Density & Bonding