At its core, lamination is a process of bonding a protective or enhancing layer to a base material. This technique is used to create a composite material that combines the properties of its individual layers, resulting in a final product that is stronger, more stable, more durable, or has a better appearance than the original material alone.

Lamination is fundamentally a strategy for material enhancement. It goes beyond simple protection to create a new, composite material with specific, engineered properties that the individual layers could not achieve on their own.

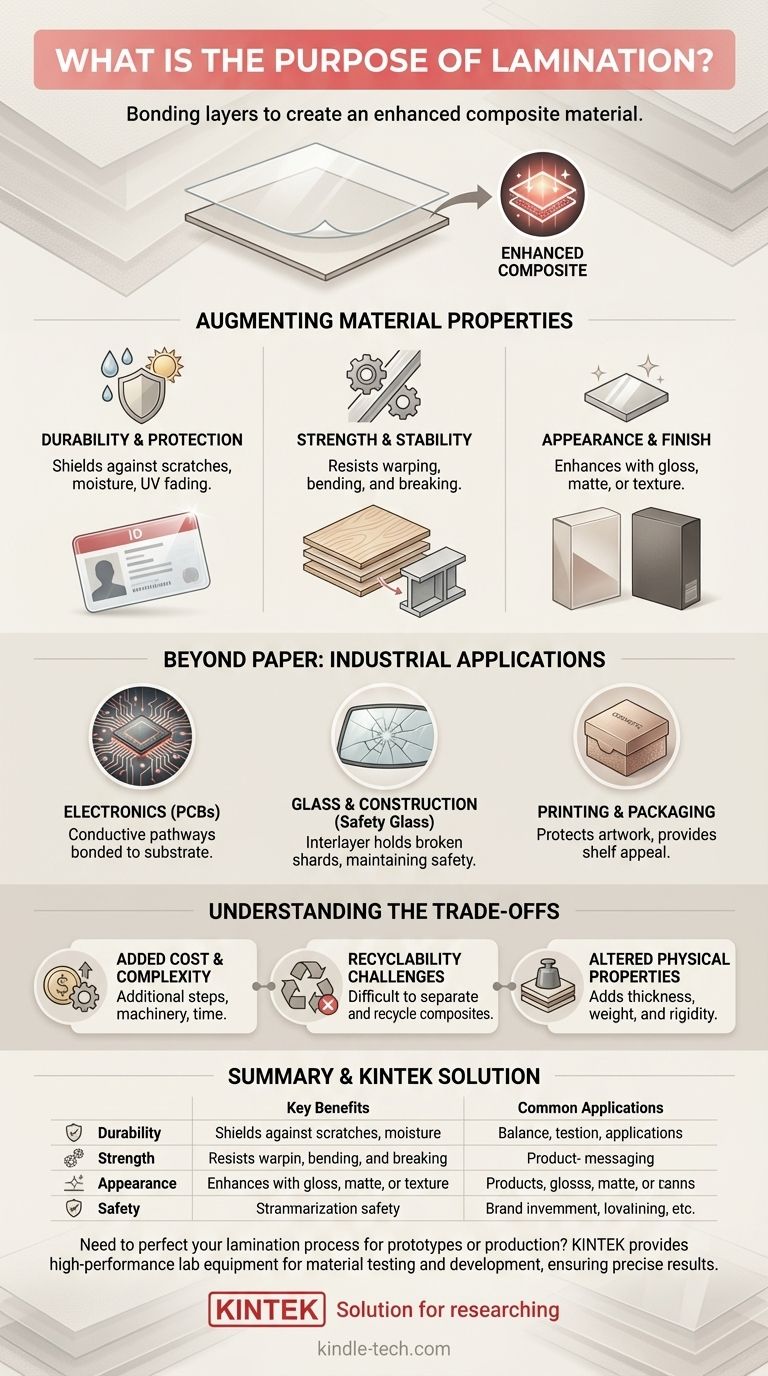

The Primary Goal: Augmenting Material Properties

Lamination is not a single action but a category of processes designed to improve a material's inherent characteristics. The specific goal determines the materials and method used.

Enhancing Durability and Protection

This is the most common and widely understood purpose of lamination. A plastic film is bonded to a printed material, acting as a physical shield.

This process offers robust protection against scratches, smudges, and spills. It also safeguards against environmental factors like moisture and UV light, which prevents colors from fading over time.

Improving Strength and Stability

In manufacturing, lamination is used to create materials that are structurally superior. By bonding multiple layers, often with different grain directions or properties, the final composite resists bending, warping, and breaking.

A classic example is plywood, where thin sheets of wood are laminated together to create a strong and stable building material. This same principle applies to high-performance components in various industries.

Modifying Appearance and Finish

Lamination is also a powerful tool for aesthetic enhancement. It can completely change the look and feel of a surface.

Applying a gloss laminate can make colors appear more vibrant and rich. A matte laminate can reduce glare and provide a sophisticated, subtle finish. Other specialty films can add texture, holographic effects, or a soft-touch feel.

Beyond Paper: Common Industrial Applications

While office lamination is common, the most critical applications are found in industrial manufacturing, where it is essential for function and safety.

In Electronics

Lamination is fundamental to the creation of printed circuit boards (PCBs). The process involves bonding layers of copper foil to a non-conductive substrate material, creating the intricate pathways that allow electronic components to function.

In Glass and Construction

Safety glass, used in automobile windshields and architectural windows, is a product of lamination. A thin layer of clear polymer is bonded between two panes of glass.

If the glass shatters, the interlayer holds the broken pieces together, preventing dangerous shards from flying loose and maintaining the structural barrier.

In Printing and Packaging

High-quality product packaging almost always involves lamination. It protects the printed artwork during shipping and handling while also providing the desired shelf appeal, whether that is a high-gloss, premium matte, or durable textured finish.

Understanding the Trade-offs

While powerful, lamination is not always the right solution. It introduces specific trade-offs that must be considered.

Added Cost and Complexity

Lamination is an additional manufacturing step. It requires specialized machinery, materials, and time, all of which add to the final cost of the product.

Impact on Recyclability

This is a significant environmental consideration. Bonding different materials, such as plastic and paper, creates a composite that is often difficult or impossible to separate and recycle through standard processes.

Altered Physical Properties

Lamination adds thickness, weight, and rigidity. While often desirable, this can be a drawback if the goal is to maintain the original material's flexibility or delicate feel.

Making the Right Choice for Your Goal

Selecting the right approach depends entirely on your end goal.

- If your primary focus is preservation and daily use: Simple thermal lamination is perfect for protecting documents, ID cards, or menus from frequent handling and wear.

- If your primary focus is product quality and appearance: Professional print lamination offers specific finishes (gloss, matte, soft-touch) to elevate marketing materials, book covers, or packaging.

- If your primary focus is structural integrity or safety: Industrial lamination is the required process for creating robust, reliable components like circuit boards or safety glass.

Ultimately, lamination allows you to engineer a final material that is far more capable than its individual parts.

Summary Table:

| Purpose | Key Benefits | Common Applications |

|---|---|---|

| Durability & Protection | Resists scratches, moisture, UV fading | Documents, ID cards, menus |

| Strength & Stability | Reduces warping and breaking | Plywood, industrial components |

| Appearance & Finish | Adds gloss, matte, or texture | Packaging, marketing materials |

| Safety & Function | Holds shattered glass, creates PCBs | Safety glass, electronics |

Need to perfect your lamination process for prototypes or production? KINTEK specializes in providing high-performance lab equipment and consumables for material testing and development. Whether you're working on durable packaging, electronic components, or new composite materials, our solutions help you achieve precise and reliable results. Contact our experts today to discuss how we can support your laboratory's specific lamination and material enhancement needs!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Touchscreen Automatic Vacuum Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- How does hot pressing work? Achieve Maximum Density for Advanced Materials